Introduction: Where 3D Printing Meets Jet Technology

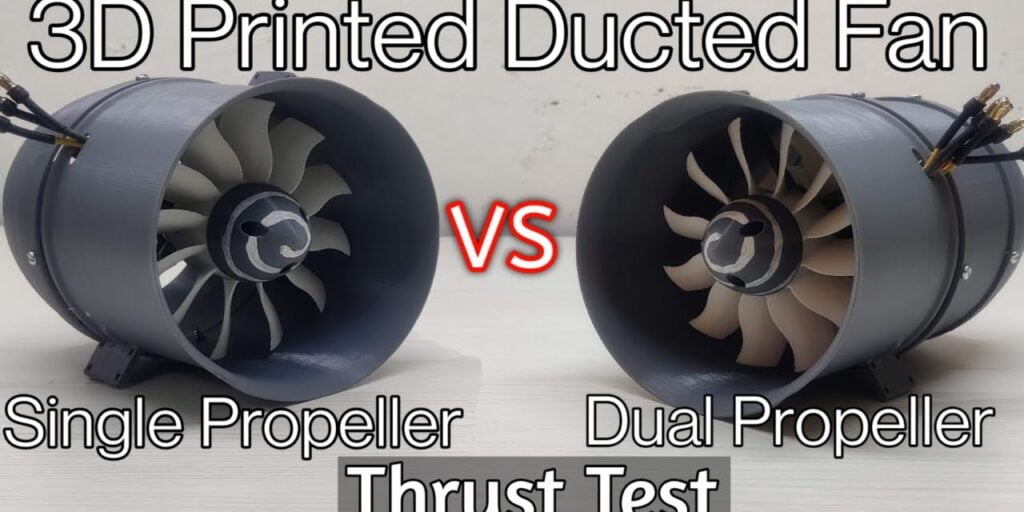

Welcome back to the MechNinja 🚀 Today, we’re diving into a project that combines two of my favorite things—3D printing and aviation technology. If you’ve ever watched a fighter jet roar across the sky, you’ve probably marveled at how much engineering goes into controlling thrust and maneuverability. One of the most fascinating pieces of that puzzle is the variable nozzle.

In this project, we recreated a variable nozzle for an Electric Ducted Fan (EDF) engine using 3D printing. Our goal? To test how these nozzles affect thrust, efficiency, and overall performance in small-scale EDF setups.

Whether you’re an engineer, a maker, or just someone curious about how jets work, this project has something for you. By the end of this blog, you’ll have a clear understanding of:

What variable nozzles are and why they matter.

How we designed and 3D printed our prototype.

The results of our thrust tests with different battery setups.

Lessons learned and what’s next for improving efficiency.

So, grab your favorite drink, settle in, and let’s explore how a piece of fighter jet tech can be recreated on a workbench with nothing more than a 3D printer, some servos, and curiosity.

Understanding Variable Nozzles

What Is a Variable Nozzle?

At its simplest, a variable nozzle is a nozzle whose opening can expand or contract. By adjusting the size and shape of the nozzle, engineers can:

Control thrust direction (vectoring the exhaust)

Increase or decrease exhaust velocity.

Balance efficiency and raw power depending on conditions.

For example:

- A converging nozzle (narrower exit) increases exhaust velocity, creating higher thrust at the expense of efficiency.

- A diverging nozzle (wider exit) can improve efficiency at lower speeds.

This is why fighter jets, rockets, and even commercial engines often rely on variable geometry nozzles—they make engines more adaptable.

Why Bring This to EDF Engines?

EDF engines are essentially mini jet engines for hobbyists. They use an electric motor to spin a fan that pushes air through a duct, generating thrust. By adding a variable nozzle, we can simulate what real jets do and explore how airflow dynamics change.

For the maker community, this experiment is exciting because it blends:

- 3D printing innovation (custom nozzles, parts, and mechanisms).

- Aviation engineering principles (fluid dynamics, thrust, efficiency).

- Hands-on learning (building, testing, iterating).

It’s like bringing a fighter jet lab to your desk.

Designing and 3D Printing the Variable Nozzle

Turning the Idea into a Model

The heart of this project was designing a variable nozzle mechanism controlled by servos. Our design featured:

Two servos that moved a slider system.

The slider controlled nozzle blades, allowing them to converge or diverge.

A structure light enough for EDF use but strong enough to withstand airflow forces.

The design wasn’t just about mechanical movement. We had to think about airflow—any gap, rough edge, or uneven blade alignment could cause turbulence and reduce thrust.

Printing the Components

We printed the parts using an FDM 3D printer with the following specs:

- Layer Height: 0.2mm for main parts (balance of speed and detail).

- Infill: 30% for strength without excess weight.

- Propeller Printing: 0.1mm layer height for smoother surface finish.

Material choice: PLA+—durable enough for testing, but for future iterations, we may try PETG or Nylon for better heat resistance.

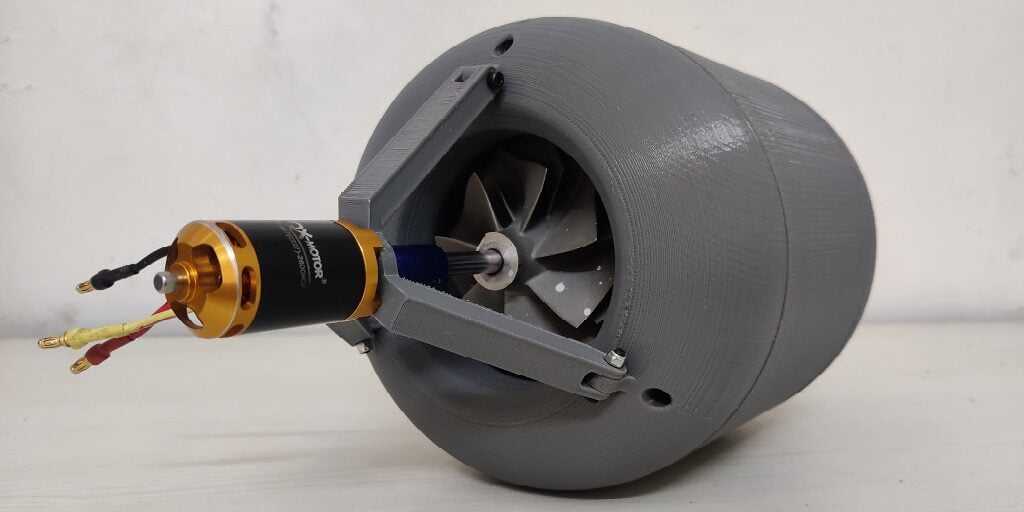

Assembly and Motor Selection

The nozzle was attached to an EDF engine powered by a 2500 KV Racer Star 2207 motor. Why this motor?

- High rotational speed.

- Lightweight design.

- Ability to generate 165 grams of thrust on its own.

The assembly process was fairly straightforward: mount the motor, attach the EDF housing, and integrate the servo mechanism for nozzle control.

Setting Up the Test Rig

Building the Measurement Setup

To measure performance, we built a test rig with:

- A wattmeter to track power usage.

- A USB connection to log data into a laptop.

- A load cell to measure thrust output.

Now, I’ll admit—the test rig is still a work in progress. The load cell wasn’t fully calibrated, so raw thrust readings needed manual adjustment. Still, it gave us enough reliable data to analyze trends and identify where improvements were needed.

Building the Measurement Setup

Testing with Different Batteries

We started by running the EDF with a 40 MPCC setup, achieving 460 grams of thrust. Since the load cell wasn’t calibrated, we added 100 grams to the readings for more accurate values.

Then we tested the engine with both 3S and 4S batteries.

Results Without Converging the Nozzle

Here’s what we observed when the nozzle blades were left wide open:

- 3S Battery:

- Thrust: 570 grams

- Efficiency: 2.01

- Thrust: 570 grams

- 4S Battery:

Thrust: 772 grams

Efficiency: 1.51

What does this mean?

On a 4S battery, thrust increased but efficiency dropped—meaning more power was consumed without proportional thrust gains.

On a 3S battery, the system was more efficient (better thrust-to-power ratio).

Why Did Efficiency Drop?

We traced the issue to the gaps between nozzle blades. These gaps created turbulence, disrupting smooth airflow. For a nozzle to increase fluid velocity effectively, it must guide air through a smooth, converging path. Our prototype didn’t achieve this, so instead of boosting velocity, it created drag.

Iterating the Design

Lessons from Prototype 1

Our first prototype was ambitious but flawed. It featured a converging mechanism that worked by tilting parts inward. Unfortunately, the motion wasn’t smooth, and airflow suffered.

Instead of scrapping the idea, we treated it as a learning step. Iteration is the heart of engineering.

Planned Improvements

For the next design, we plan to:

- Redesign nozzle blades for a tighter seal and smoother airflow.

- Experiment with curved internal surfaces instead of flat ones.

- Reduce moving parts to minimize friction and weight.

- Test new materials like PETG for flexibility and durability.

- Improve calibration of the test rig for more accurate measurements.

Each prototype takes us closer to a variable nozzle that genuinely improves thrust.

Why This Experiment Matters

This isn’t just about numbers on a test rig—it’s about making aerospace technology accessible.

- For hobbyists: It’s a chance to add realism to RC planes and drones.

- For students: It’s a hands-on way to study propulsion and fluid mechanics.

- For innovators: It’s a playground for testing low-cost prototypes before investing in expensive manufacturing.

In other words, projects like this democratize technology. You don’t need to be NASA to experiment with thrust vectoring—you just need a 3D printer and persistence.

Challenges We Faced

Every project has roadblocks, and this one was no exception:

- Airflow smoothness: 3D prints aren’t as precise as CNC machined parts.

- Heat resistance: PLA may warp under prolonged high-speed operation.

- Servo durability: Continuous movement strains hobby-grade servos.

- Measurement accuracy: Without proper calibration, test results can mislead.

But here’s the thing—challenges fuel creativity. Each limitation forced us to think differently and refine our approach.

What It Felt Like

On a personal note, working on this nozzle felt like a blend of engineering and art. Watching the servos move, hearing the EDF roar, and seeing thrust values appear on the screen—it’s the kind of satisfaction only makers understand.

Sure, the numbers weren’t perfect, and efficiency dropped where we expected gains. But the beauty of projects like this isn’t in getting it right the first time—it’s in learning, improving, and sharing the journey with a community that’s just as passionate.

Get Involved and Stay Updated

We’re not stopping here. The next prototypes will push for higher efficiency, smoother airflow, and more realistic variable nozzle movement.

👉 If you’ve got ideas, feedback, or experience with similar projects, share them in the comments!

👉 If you found this blog useful, don’t forget to share it with friends or communities that love 3D printing and aviation.

Join the MechNinja 3D Printing Community

Want to try this yourself? We’re making the STL files for our nozzle and other projects available on our MechNinja website.

Stay inspired to push the limits of what 3D printing can achieve.

Get access to unique designs.

Connect with fellow makers.

Conclusion: Small Nozzles, Big Lessons

This experiment with 3D printed variable nozzles showed us just how delicate the balance of thrust, efficiency, and design really is.

- Our prototype didn’t deliver the expected gains—but it gave us invaluable insights.

- We proved that 3D printing can replicate and test aerospace concepts.

- Most importantly, we learned where to improve, and that’s the essence of innovation.

In the end, this project is about more than thrust numbers—it’s about bringing fighter jet technology into the hands of makers and turning complex aerospace ideas into something tangible, testable, and fun.

So stay tuned—the journey has just begun. And remember: sometimes the most exciting part of innovation isn’t the destination, but the experiments along the way.