Have you ever experienced any major issues with your 3D printer nozzle? If yes then you know how much frustrating they can be frustrating, we have faced the same in the past. In this article, we will give you some powerful tips and tricks to help you find the solution to your 3D printing nozzle problem. We found these solutions for 3D printer nozzle issues after many trials and errors, after spending a lot of our time with persons associated with the field and experimenting on our own.

What are some common 3D Printer Nozzle issues? Some of the most common 3D printer nozzle issues include a jammed nozzle, uneven layer size, an irregular diameter of the layer, etc. Whether you’re using PLA, ABS, or some other material, the nozzle can hold enough material in its tip that each droplet is no larger than 20 micrometers in diameter. Here we are also going through some of the most common causes so that you can avert any future malfunctions and make sure that your 3D printer continues to work properly.

In The Post:-

- What is a 3D printer nozzle?

- 3d Printer Nozzle Issues: Causes

- Design

- Bed Alignment

- Extruder

- Heating Element

- 3d Printer Nozzle Issues: Simple Solutions

- How to test for nozzle problems?

- Quick Solution To Most Basic Issues

- Cleaning The Nozzle

- Replacing Nozzle

- Nozzle Calibration

- Temperature Adjustments

- Checking The Filament

- 3d Printer Nozzle Issues: Synopsis

What is a 3D printer nozzle?

To simplify, the 3D printer nozzle is a tube inside your 3d printer, which is responsible for melting the filament and then extruding it in the proper direction to produce a finished plastic part when you click on print. It also forms the base of your 3D-printed object so that it can be removed from your 3D printer.

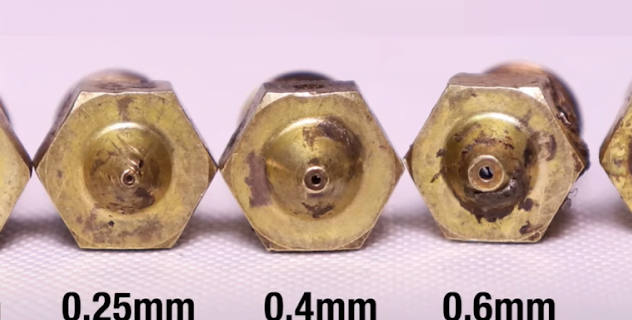

These come in various sizes and materials depending upon their use. Changing and assembling 3D printer nozzles is also a hefty task and this also causes many problems, so to help you there’s a blog by us that you can read.

Your 3D printer needs to work properly. And as such, when it malfunctions, it can be a nightmare to deal with. Before we get too much into the technology behind an issue like this, let’s cover the common causes of nozzle issues first.

3d Printer Nozzle Issues: Causes

Many issues can cause nozzle problems. These include nozzle jamming, due to excessive heat or the use of unsuitable material, for example.

Design

Poor design can also lead to problems with nozzles. A printer may have a compact design, meaning the extruder is positioned close to the print bed. This means that if printing ABS plastic filament, ABS droplets may build up on the bed and catch fire because of the heat generated by the hot-end nozzle during operation.

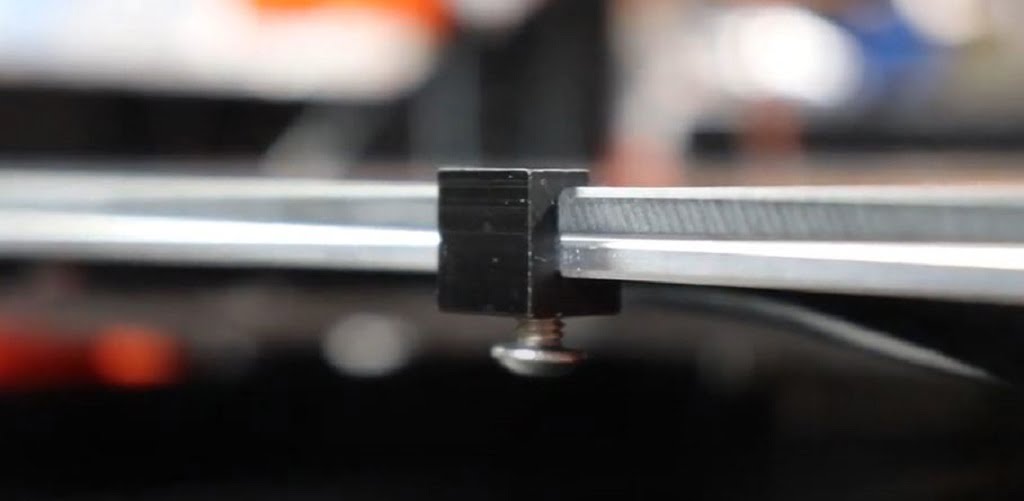

Bed Alignment

Poor alignment of the print bed can lead to problems with the extruder nozzle. The feeder head should have a relatively small gap around it to feed the filament into the nozzle. A poor design may include a large gap, which means that material is not drawn in properly and may build up on the extruder nozzle.

3D Printer

An excellent 3D printer should be designed to make it easier to find and service any printer component when required. This can include access to electronics as well as mechanical parts. This is usually achieved with the use of a robust and quality enclosure.

Extruder

The heated extruder on many consumer printers, especially those based around Fused Deposition Modeling (FDM) technology, may also be prone to nozzle failures.

Heating Element

In addition to the nozzle, problems can occur with the heating element. If a printer has a heater cartridge, this can become damaged by using unsuitable material or failure to heat the extruder properly.

Heated housings are particularly susceptible to damage through excessive heat and failed nozzles. If a nozzle is damaged and returns hot plastic to the housing, it may degrade the thermal stability of the 3D printer.

How to Upgrade Your 3D Printer Nozzle – Simple Steps

3d Printer Nozzle Issues: Simple Solutions

Make sure that your extruder’s nozzle is clean and oiled.

A small amount of lube can help keep the nozzle running smoothly by preventing small pieces of debris from lodging themselves inside of it. Make sure to remove any excess lube or debris before you start printing again, as it can cause streaks or smudges on the melted filament.

Use a different extruder if possible.

If the nozzle can output a quality print but has issues when printing in ABS, it could be caused by a build plate misalignment or an issue with the extruder’s stepper motor. It is recommended to use a different extruder for printing in ABS to avoid damaging your hot end and its components.

Check to make sure that the filament path is sealed.

If there are no problems with the printing and the extruder seems to be working properly, it’s time to check the design of your 3D printer’s extruder. First, open up your 3D printer’s disassembled hot end and take a look at its components. There should be a set of nozzles similar to your printer, along with some plastic or steel tip for measuring and directing the fed filament.

How to test for nozzle problems?

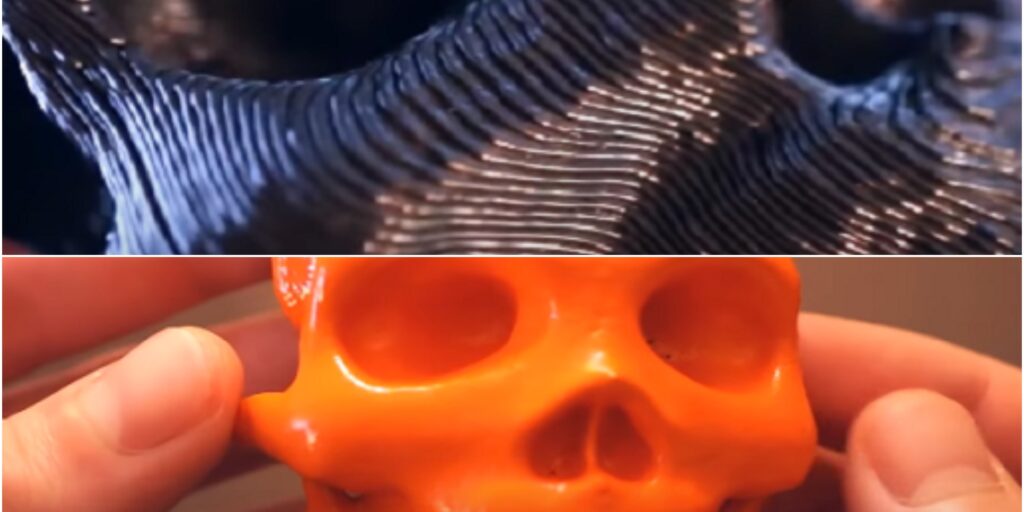

The 3D printing nozzle is a crucial element of the extruder. The filament is forced through the nozzle and comes out molten before cooling and becoming solid on the build platform. If there’s a problem with your 3D printer’s nozzle, it can cause air bubbles to form, inconsistent flow rates of filament to occur, or an inability to heat up and melt correctly.

Check the quality of output.

The first way to test for a possible problem with your nozzle is by checking if any issues are due to items that are being printed. The printer may struggle to print thin walls or tiny details properly, or problems may arise when printing in ABS, as the ABS may begin to shrink and be permanently misaligned.

If testing the item shows that it is indeed printing correctly and without errors, inspect the extrusion path of your nozzle using an inspection scope from Flexible Printed Circuit Board. Pay close attention to the filament’s steps to get to the build platform.

Check Out Our Latest Designs For Your Next Project

Quick Solution To Most Basic 3D Printer Nozzle Issues

- Cleaning the nozzle: A clogged nozzle can be caused by debris or filament residue. To clean the nozzle, you can use a small wire or needle to clear out any blockages, and then run a cleaning filament through the nozzle to remove any remaining debris.

- Replacing the nozzle: If the nozzle is worn or damaged, it may need to be replaced. You can purchase replacement nozzles for your printer model, and then follow the manufacturer’s instructions for installing the new nozzle.

- Calibrating the nozzle: Incorrect nozzle calibration can also cause issues. You can use your printer’s software to adjust the distance between the nozzle and the build plate and the flow rate of the filament.

- Adjusting Temperature: The temperature of the nozzle should be adjusted according to the type of filament you’re using. If the nozzle temperature is too low, the filament may not melt properly, which will cause issues with the print.

- Checking the Filament: Incompatible or low-quality filament can also cause nozzle issues. Make sure that you’re using filament that’s recommended for your printer model and that it’s stored properly to avoid moisture absorption.

How can I replace my nozzle?

Nozzles are easily clogged with plastic filaments to ensure that there will be no buffer between the molding part and the nozzle. Moreover, if you want your printer to output better-quality printings, you should periodically replace your nozzle depending on its usage.

If your nozzle is damaged or clogged, you can replace it with a new nozzle. You need to know the right tools at hand and find out how to do the replacement.

Requirements:

- Screwdriver (flat head) and small pliers/wire cutters (if required) to tighten the screws on nozzles (it came with the machine) and tighten screws that hold belts.

- Glue/epoxy for the replacement nozzle; any glue/glue stick will do.

- Nozzle.

- Clean burning gas, such as Propane, compressed air, and so on; other gas may cause damage to the nozzle as some gases produce a lot of heat and cause the vaporization of plastic filament. Any oxidizing agent can also be used as it is easy to clean up with water.

- Spare parts: If the old nozzle had been covered with paint or the plastic material was in poor condition. It’s best to prepare a replacement nozzle before taking off the old nozzle.

Some of the most basic causes of 3D Printer nozzle issues are due to faults or issues in bed alignment, design, extruder, heating elements, etc.

Some of the quick solutions for basic 3D printer nozzle issues are cleaning the nozzle, replacing the nozzle, calibrating the nozzle, doing temperature adjustments, checking the filament, etc.

3d Printer Nozzle Issues: Synopsis

There are solutions for every type of nozzle issue, and if you’re a 3D printer owner, you’re not alone. If any of the above-mentioned issues are seen with your printer, try the tips above, if still you can’t solve the problem comment below we will try to help you with our best knowledge.

Remember that printers are delicate instruments and should be properly maintained.