The nozzle is one of the most stressed mechanical parts in your 3d printer, it faces multiple harsh situations. But most of us are not unable to recognize that our nozzle is getting damaged because nozzle damage starts internally. So it is necessary to do a 3d printer nozzle upgrade. Also, the nozzle has to work as a medium for heat to transfer enough heat from the heater cartridge to melt the filament.

What is the best way to reduce nozzle damage? The best way to reduce nozzle damage is by upgrading it to a tougher material like carbon fiber nozzle or ruby tip nozzle. But, upgrading depends upon several factors, these factors are discussed in the post below. 3d printer nozzle upgrade is crucial even for a person who uses a 3d printer for a long time.

In The Post:-

- Signs For Nozzle Upgrade

- Specifications While Upgrading 3D Printer Nozzle

- Changing The Extruder Nozzle

- FAQ

- Conclusion

Signs For Nozzle Upgrade

When you see your nozzle closely you will find that your nozzle tip is worn out and its tip bore diameter is increased. You can also see that your nozzle length is reduced due to continuous use of the part, resulting in excessive tearing of the nozzle tip.

Sometimes people did not level the heatbed correctly thus nozzle crashes into the heated, this whenever happens results in extensive damage.

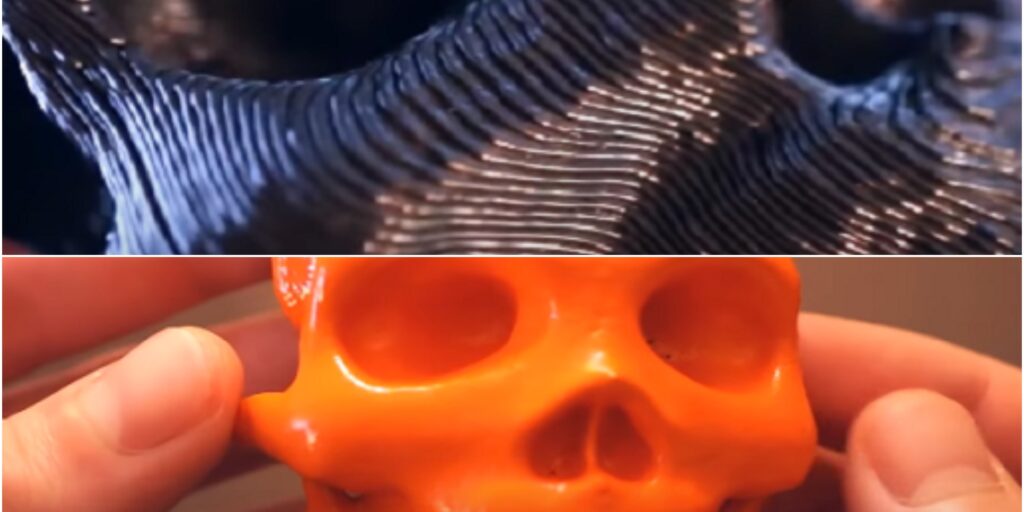

When you normally use FDM filaments like PLA or PETG your nozzle is long last but when you try some filament with composite materials or a blend of any other material then your brass nozzle starts getting damages. The tiny particle of material which is mixed with filament starts scratching your brass nozzle internally after long use you see that your nozzle tip now larger in diameter because tiny particle which is mixed with filament is harder than brass particle so they tear out the brass nozzle.

Also, when you try to change the nozzle, there is a risk of heartbreak damage. Heartbreak is a thin outer threaded pipe that provides a smooth way for filament towards the nozzle also separates the heat block from the heatsink which helps it to cool down. If you only upgrade the nozzle of your extruder your print quality gets better because some times nozzle is clogged partially which we can not see from our eyes until we got some major issues in print.

Need to Upgrade The Nozzle

When your 3d printer nozzle gets damage, your print quality is down. You can see that your printed parts have blobs, a Rough print surface, bad layer adhesion, and over and under extrusion problems. Often your nozzle is getting clogged again and again.

Precaution While Upgrading 3D Printer Nozzle

Remain these things Whenever you are going to replace or upgrade your extruder nozzle.

- Nozzle Length

- Build Material

- Tip Size or Bore Diameter

Nozzle Length

We know that nozzle conducts heat from heat block to filament for melting so nozzle size matters when you required high-speed extrusion. The longer nozzle has a larger contact area with the heat block so it conducts heat faster than the short-length nozzle.

In the market, you can find different length nozzle so if try to use a larger length nozzle, you also need the heat block that supports that large nozzle. Currently, three different types of length nozzle are used:-

- Standard Nozzle – 13mm

- Volcano Nozzle – 21mm

- Super Volcano Nozzle – 50mm

Standard Nozzle

The brass nozzle which comes with the extruder is a standard nozzle for 3d printer. It has a 13mm length and M^ thread on the outer surface. It is mostly used with V6 and MK8 hot-ends.

Volcano Nozzle

This nozzle only fits in volcano hot-end because it has 21mm length due to more length than v6 nozzle it requires a large heat block to fit the nozzle completely also it conducts more heat than v6 so its extruding speed is higher than V^6 and MK8.

Super Volcano

Super Volcano is another version of volcano nozzle it has a length of 50mm so its extruding speed is very high but you need a high-power heater cartridge also for it to provide enough heat.

Build Material of Nozzle

If you use only PLA filament then you do not require a harder meta nozzle than brass but if you also want to print with composite materials like(Carbon fiber, Glass fiber, etc) or want to use different blends of materials filament then it is necessary to choose harder material nozzle. Different materials conduct heat at different rates so it is also important to choose the current material Nozzle.

- Stanless Steel Nozzle :- Best for use with different blend of filament because steel is enough hard to exicle all different filamnet blend scratches. But it also less thermal conductive than brass but also achieve higher themprature with stainless steel nozzle.

- Hardened Steel nozzle :- If you going to print with composite or fibre filled filament than hardend steel nozzle best for you. It is more hard than normal steel nozzle also less thermal conductive than stainless steel nozzle.

- Cooper Nozzle :- If you want more extrusion speed or want more fast heat conduction between filamnet and heatblock than nickel plated cooper nozzle is best because cooper conduct heat fast. Hot coper oxidize fast so cooper nozzle comes with nickel coating.

- Ruby Nozzle :- This nozzle is assemble type nozzle because it has two material is structure. Outer part of nozzle is made of any meatl but internal part of nozzle or tip of nozzle is made of ruby crystal which are not going to wear out by any kind of abrasice materialfulament. If you want to pritn with metal filled fiilamnnet than this best for you.

Nozzle Tip Size

Nozzle tip or bore of the nozzle tip is also important you want to control the speed or quality of your 3d print. Small nozzle tip bore gives you high print details of smooth surface finish but extrudes slow and increases your print time. While on the other hand large-bore nozzle tip extrude fast and your print is less but you do not get a smooth surface finish and your layer of the print is visible.

Changing The Extruder Nozzle

After knowing the nozzle’s important aspect, we see how to upgrade or change the 3d printed nozzle. To change the extruder nozzle follow the given steps:-

Note:- All The rotation of the nozzle give on basis of that nozzle is faced toward the user not below or in any other direction.

Steps for 3d Printer Nozzle Upgrade

Removing The Old Nozzle

- First Remove the filament from the hotend you can do this by cold pull without heatup the hotend or if you want to do firmly heat up the extruder to 170oC than pull the filament back.

- After removing the filament now turn off the power supply off.

- Before the hotend became cold again you have to remove the nozzle, take a wrench and hold the heat block with it than use another wrench to make grip on nozzle now rotate the nozzle anticlock-wise and your nozzle come out from the heat block.

Upgrading New Nozzle

- For adding new nozzle in extruder Put high temprature thermal compund on nozzzle threads.

- Now put nozzle in heatblock hole and rotate it clock-wise through hand

- At use wrench to hold the heat block and another wrench to rotate the nozzle clock-wise with little force.

- Don put to much force.

- Now heatup the extruder to 250oC.

- You extruder is ready to print.

FAQ on Nozzle Upgrade

For abrasive material use, you should prefer a carbon fiber nozzle or ruby tip nozzle. Both nozzles are pretty durable and will last longer than any other type.

The main reason behind the nozzle tip bore diameter getting uneven is the use of composite filaments. These filaments have abrasive material particles mixed in them and thus cause surface damage to the nozzle tip.

Conclusion

As you see that nozzle type depends on your work type, you can also choose the ruby nozzle which has done a good job with all types of filament but it also has a high price tag. But if you did not go to use a metal mix filament or composite material regularly or for a long period of print then a normal steel nozzle is best.