3d printer Nozzle is most common but one of the major parts of a 3d printer. Your print surface finish depends on the nozzle also. The overall performance of the part in load conditions also depends on the nozzle.

Now, the question arises, Why Do We Need To Worry About 3d Printer Nozzle?

3d printer nozzle is the part that is responsible for better extrusion of melt plastic, the good flow rate of the extruder, heat transfer to the filament, or less maintenance of 3d Printer. In this post, we will discuss the effects that a nozzle imparts on our prints. We will also talk in detail about these effects. So first let’s have a list of the effects of a nozzle on a 3D printer.

- Print Time

- Surface Finish

- Print Strength

- Filament Flow Rate

- Even Extrusion

- And many more

3D Printer Nozzle

Print Time

In one sentence we can say that “Nozzle diameter determines print time”. Standard Stock Print nozzle is 0.4mm which is a good balance between speed, quality, and strength of finish print. But if you want that your printer to print your part with a very good surface finish so small size nozzle is best. As the nozzle size is decreased printing details will surely strengthen but the printing time also increases.

If you did not need the best surface finish of the part then, you can choose a large bore diameter nozzle. It decreases the printing time but you also need a better heat cartridge to Heat up the filament in less time.

If you are not able to heat up the filament fast so a large nozzle size is not good because it clogged at some point due to uneven heating.

Thus we can say that print time and print quality are directly proportional to each other. If you want print time to be less then quality will be less and if you want better quality then you have to give more time for printing.

3D Printer Nozzle

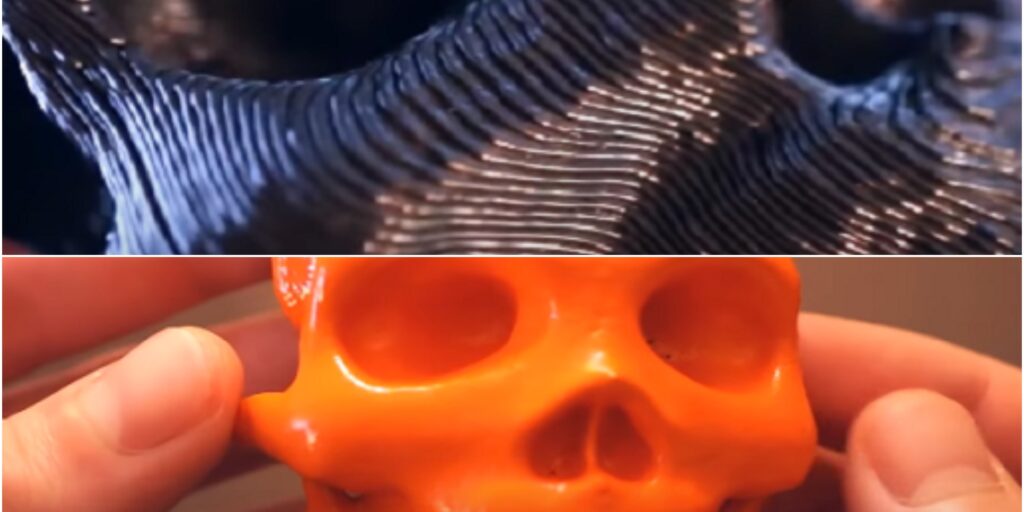

Surface finish

Larger nozzle bore diameter prints large layers so your layers are visible in finish print. In high detailed print, you need to use a less bore diameter nozzle thus it decreases the height of the layer and results in a glossy surface finish.

Also less bore diameter nozzle did not require high temperature because extruder speed is slow in detailed print thus filament get enough time in the nozzle cavity to melt evenly.

3D Printer Nozzle

Print Strength

Printed part strength determine by many factors. One of the factors is the nozzle also. If you want to print high-strength parts you can choose a large bore diameter nozzle it also reduces the print time.

But if you increase the extrusion width is setting so can print high-strength parts with a small-bore diameter nozzle but it decreases the surface finish also it takes the same time.

3D Printer Nozzle

Filament Flow Rate

You did not require a high-temperature heater in a small-bore diameter. In this type of nozzle, the filament gets enough time to get melt also filament feed rate is slow. But the flow rate is slow to maintain the details of prints.

In large bore sizes, nozzle printers require a high-temperature cartridge heater so the filament can get melt in less time because the feed rate of filament is High. You can achieve a high flow rate in a large-bore nozzle because of no restriction of surface finish.

Miscellaneous

The large bore nozzle filament feed rate is high so filament has a small time to get melt so the result is gaps in print. If you want to use a large-bore Nozzle, you need a high-temperature conductive heat block or high-temperature heater cartridge.

3d Printer Nozzle Types

According to your need, there are many different types of nozzles are available in the market. If you want to print only in PLA so you can use a normal brass nozzle or you want high reliability on the nozzle so you can use a copper nozzle.

If you use abrasive material (like- carbon fiber filament, metal filament, wood filament) so you can go with Steel or Ruby tip nozzle. Types of the nozzle.

- Brass Nozzle

- Stainless Steel Nozzle

- Copper Nozzle

- Hardened Steel Nozzle

- Assembled Nozzle

Brass Nozzle

Brass nozzle is cheap and used by most the of 3d printer extruder. You can only use non-abrasive material with brass due to its softness. The brass nozzle comes in different sizes and shapes and also in different internal surfaces.

Stainless Steel Nozzle

Stainless Steel nozzle has more hardness than brass. So you can use them with abrasive material but only with some. Stainless Steel nozzle is less temperature conductive than brass. If you want to print with food filament so you can use Stainless Steel Nozzle It did not contaminate it with lead.

Copper Nozzle

You cant use only copper nozzle they come in many plated formats. If you want to print with high temperature or sticky filament then a nickel-plated copper nozzle is best.

Hardened Steel Nozzle

Hardened Nozzle is for printing with abrasive materials. But there is also a flaw that it is not very good heat conductive so your heat bock temperature may differ from the internal temperature of the nozzle.

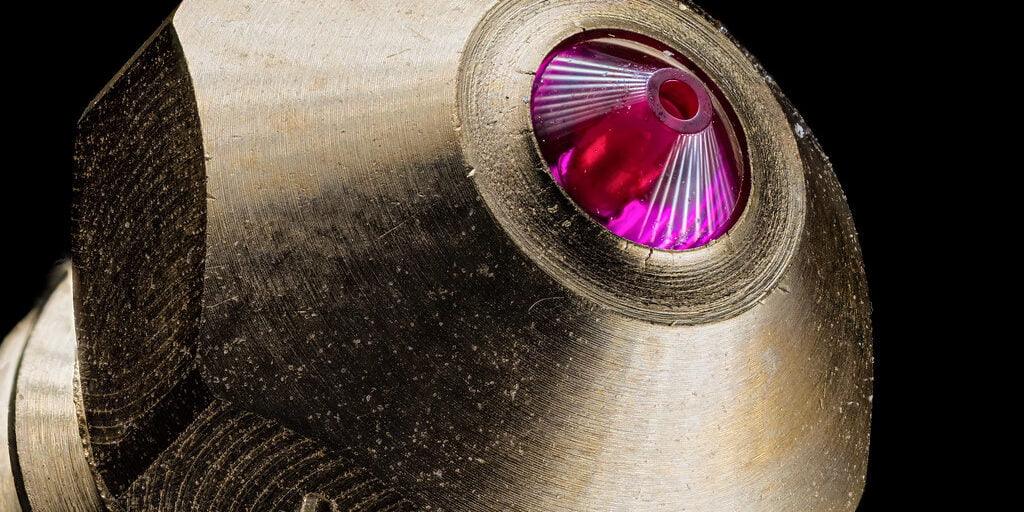

Assembled Nozzle

In assembled nozzle manufacturers use two or more different materials for construction of different sections of nozzle for better use of metal properties for all parameters. They often use for printing with abrasive material.

Pay attention Nozzle Length And Thread Spacing

If you are building a custom Extruder or Buying Extruder in parts from different manufacturers so you need to worry about some parameters which are given below:-

Length Of Nozzle

Space between Nozzle and Heat Brake Pipe. If your extruder heat block has spacing between heartbreak pipe and nozzle so that space filled with filament and it directly affects your extruded amount of filament RATE.

Nozzle And Heat Block Threads

Nozzle thread and heat block thread also have to connect perfectly because threads are the only surface which touches the surface of heat block. If the threads are not the same then first it nozzle is not screwed in the heat block and if the nozzle is screw then heat transfer from heat block to nozzle may differ. It resulted in gaps in printing layers or under extrusion problems.

3d Printer Nozzle Pros and Cons

Small-bore diameter nozzle

| Pros | Cons |

|---|---|

| Achieve high details on prints. | Print takes a lot of hours. |

| A standard heater cartridge is enough. | A single small particle of dust can block the nozzle. |

| Use with the high-speed print head. | Higher chances of filament blockage. |

Large Bore Diameter Nozzle

| Pros | Cons |

|---|---|

| Printing of large parts becomes much easier. | There is hardly any surface finish. |

| Jamming of Nozzle chances is much lower. | Requires high temperature. |

| Easy manitenance. | Not efficient for 3D miniature printing |

3D Printer Nozzle FAQ

The 0.4mm diameter 3D printer nozzle is the most common and balanced nozzle in the 3D printing industry. It has good printing speed with good finishing of the part.

Based on the material they are made of 3D Printer nozzle are mainly of five types i.e. Brass, Stainless Steel, Copper, Hardened Steel, and Assembled Nozzle. The most common in them is the Brass nozzle mainly because of its price efficiency.

That’s it we hope that you have found answers to all the questions related to the 3D Printer nozzle. If you have any doubts or questions please ask them in the comment box below. Share it with your friends and colleagues and help us grow as a community.