Polycarbonate filament is one of the in-demand filament used in 3D printing. It is one of the main materials which is used in making them. It is a great material for 3d printing due to its multiple properties like (High heat resistance, Transparent, high dimensional stability, and amorphous. It is also an electrical Resistance.

Have you ever wondered about what actually Polycarbonate Filament contains?, How much force it can withhold?, What is the optimum temperature for its working, and many more general questions about Polycarbonate filament will be answered in this blog?

Before the review, the polycarbonate filament lets take a look at the Material structure and properties

Polycarbonate Filament

Know Your Material

Polycarbonate is tough and heats resistant thermoplastic with organic functional groups linked together with other carbonate groups. Polycarbonate is optically transparent.

It has a tensile strength of 55-75 Mpa and compressive strength of more than 80 Mpa.

This filament has multiple applications. It is used in Regular household items, Aerospace, Medical fields, Data storage, and Security components.

Polycarbonate Filament

Polycarbonate Filament

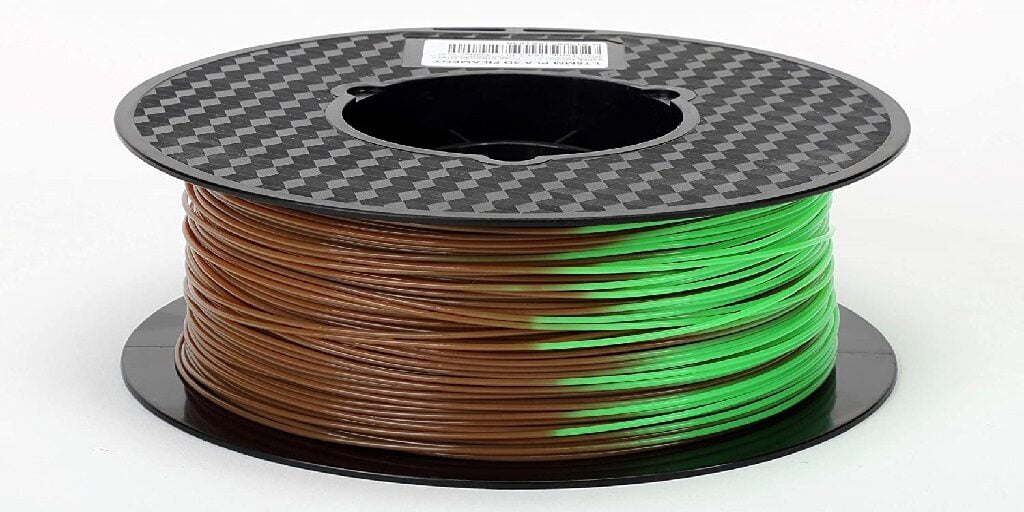

This filament comes in many different colors due to its blend of different materials but the original comes in black, white, and transparent. It is also known as PC filament. It is also a good electrical Insulator so you can use it to design Electrical instrument boxes.

Before doing anything with the filament read the filament manufacture guide to print with it because many different manufacturers use different blends with Polycarbonate to make these Filaments.

It is not easy to print with Polycarbonate due to the Required High Nozzle temperature, Wrapping, and Cracking in prints so you need an enclosure to keep the temperature the same.

Polycarbonate Filament

Required Hardware

Polycarbonate printing requires a high temperature to melt so needs an All Metal Hotend and enclosure(not always according to filament manufacturer brand) to stop wrapping.

It is also abrasive type material (abrasive means it, rube, your nozzle internally and damage its point). So you need to use a Stainless steel nozzle which is enough for PC filaments.

Polycarbonate Filament

Precautions

Polycarbonate Filaments also absorb moisture from the air easily. So you need an airtight container to keep them dry. If they absorb moisture so need to first dry the filament before using it.

You can use one of the following method to dry the filament

- Microwave oven

- Food dehydrator

- Filament Dryer

- Any other DIY filament dryer

After drying the filament you can use them but after use place them in an airtight container. Also, you can make a hole in the container to take out the filament from it thus you do not expose the full spool of filament to moist AIR.

Polycarbonate Filament

Printer Setting

Most people often did not use polycarbonate filament for regular printing but when you need heat resistance and Impact resistance so PC is also good. Here are some points that you need to do on Printer configuration before starting printing.

- Turn off layer colling Fan.

- Print under 20mm/s, this speed is most efficient, although it varies from printer to printer.

- Minimize the Retraction distance to less than 10mm.

- Polycarbonate generates fumes, so do not print in a closed room, prints in a well-ventilated place.

- Use Heatbed adhesive like:-glue stick

For HeatBed

For Heatbed use minimum temperature 100oC and print with a large brim connected to the print object to minimize the wrapping.

Latest Posts

- Exploring Thrust Variations with Variable Nozzles in 3D Printed EDF Engines

- DIY Parachute for Drone | 3D Printed Safety System That Saves the Sky

- DIY 80mm EDF And Thrust Test – All Steps

- DMLS 3D Printing Advantages & Disadvantages | Detailed

- 3D Printer Nozzle Issues | Solution & Details

- The Best & Cheapest IDEX 3D Printer | 2022

Polycarbonate Filament

Best Polycarbonate Filaments Brands

3DXTech ezPC

ezPC is created for people who want to start with PC. The company says that ezPC offers low wrapping with all mechanical properties and heat resistance.

| Properties | Value |

|---|---|

| Extruder Temperature: | 255 – 275oC |

| Heatbed Temperature: | 90 – 110oC |

| Enclosure: | Not Required |

| Bed Adhesive: | Required |

| Drying Time: | At 80oC for minimum 3 Hour |

| Supports Type: | Best with water-soluble supports |

3DXTech ezPC Filament Rating 4.6/5.0

3DX Tech

It is a Premium type PC filament from 3DX Tech. You need the best of your printer setting to print with it.

| Properties | Value |

|---|---|

| Extruder Temperature: | 280 – 310oC |

| Heatbed Temperature: | 110 – 120oC |

| Enclosure: | Required |

| Bed Adhesive: | Required |

| Drying Time: | At 120oC for minimum 3 Hour |

| Supports Type: | Best with water-soluble supports |

3DXTech Filament Rating 4.0/5.0

3DX Tech ESD

These filaments give your part safety from Electric Static Discharge. So you can use this for the enclosure of Electronics or any other items which required ESD Safety.

| Properties | Value |

|---|---|

| Extruder Temperature: | 260 – 300oC |

| Heatbed Temperature: | 110 – 120oC |

| Enclosure: | Required |

| Bed Adhesive: | Required |

| Drying Time: | At 120oC for minimum 3 Hour |

| Supports Type: | Best with water-soluble supports |

3DXTech ESD Filament Rating 4.2/5.0

Polymaker PolyMax

PolyMax has extreme strength and toughness with heat resistance and print quality. In a video, the company shows his PolyMAax Polycarbonate filament printed hook lift almost 800 kg of raw polycarbonate and break on 850 kg. It has 59.7 Mpa Tensile Strength.

| Properties | Value |

|---|---|

| Extruder Temperature: | 250 – 270oC |

| Heatbed Temperature: | 90 – 105oC |

| Enclosure: | Necessary |

| Bed Adhesive: | Necessary |

| Drying Time: | At 75oC for minimum 6 Hour |

| Supports Type: | Water-soluble supports are best |

Polymaker PolyMax Filament Rating 4.4/5.0

Polymaker PloyMax PC-FR

PC-FR is a flame retardant filament that also achieves V0 performance in the UL94 flame retardancy test according to the company. It also consists of toughness and strength.

| Properties | Value |

|---|---|

| Extruder Temperature: | 250 – 270oC |

| Heatbed Temperature: | 90 – 105oC |

| Printing Speed: | 30mm/s – 50mm/s |

| Enclosure: | Necessary |

| Bed Adhesive: | Necessary |

| Drying Time: | At 75oC for minimum 6 Hour |

| Supports Type: | Water-soluble supports are best |

Polymaker PolyMax PC-FR Filament Rating 4.3/5.0

eSUN ePC

It is cheap and gives you the same qualities that other filaments brans of PC give you. PC is Tough, Rigid, and flame retardant also. It comes in 0.5 kg or 3kg pack.

| Properties | Value |

|---|---|

| Extruder Temperature: | 230 – 240oC |

| Heatbed Temperature: | 90oC |

| Printing Speed: | 30mm/s – 50mm/s |

| Enclosure: | Necessary |

| Bed Adhesive: | Necessary |

| Enviorment Friendly: | Yes |

| Toxicity: | Minimal |

eSUN ePC Filament Rating 4.8/5.0

PC filaments also come in many other blends, some manufacturers also use recycled material for their PC filament.

If you want to become an expert in 3D printing then PC is best for prototyping due to its mechanical and thermal properties.

Polycarbonate Filament

FAQ

Is Polycarbonate Filament okay for daily basis 3D printing?

If you are using it for some structural testing prototype then it is the best filament. But, if you are a hobby printer then we would recommend minimizing the use as they require too much attention.

What are some top brands that provide polycarbonate filament?

There are many companies out there which are dealing in polycarbonate filaments some famous of them are 3DX Tech, Polymaker, and eSUN.

Is it okay to keep polycarbonate filament in open enviornment?

One should not keep polycarbonate filament in the open air as they tend to absorb moisture from the air. Once they absorb moisture then you will need to dry them before use.

Polycarbonate Filament

Conclusion

Polycarbonate filaments have great strength and structural properties but they require too much precautions. Thus if you are not in structural prototyping then we will recommend to keep working with traditional PLA and other type filaments.

We hope that you liked our post on “Polycarbonate Filament A to Z and Best 5”. Please share with your friends and colleagues so that we can get their reviews. If you have any question or doubt ask in the comment box.

Thank You.