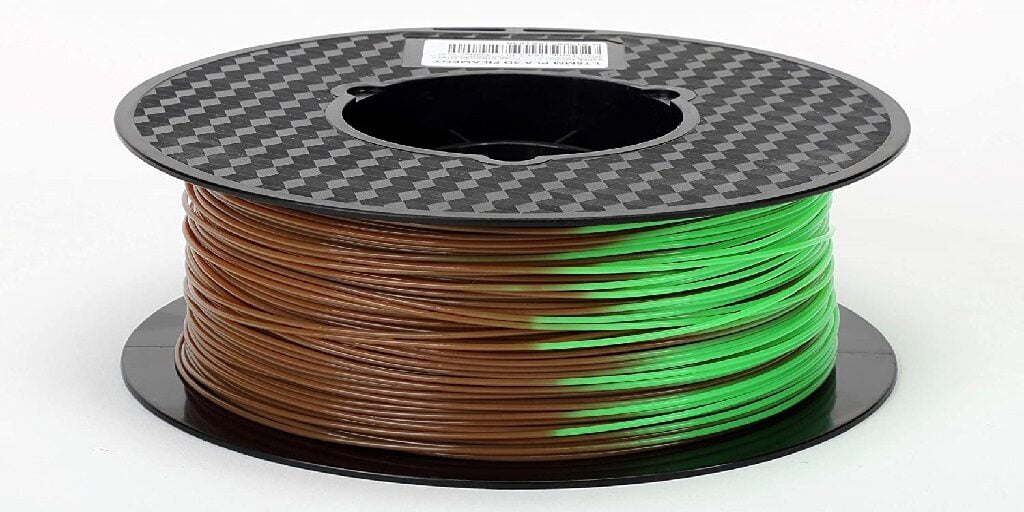

To remove unnecessary moisture from the material, placing filament spool in an appropriate dry location or having a device to dry it is compulsory. The temperature and time at which heating action should be carried out depends on the material used. This article will shed light on reasons and methods of how to dry flexible filament.

What are simple ways to dry Flexible Filament? The best method is to use a filament dryer or oven to dry our flexible filament. There is no separate procedure for drying flexible filaments, you can use the methods mentioned in the post for any type of filament.

Drying of FLecible Filament becomes necessary as they are more prone to stringing and oozing. When they have moisture in them they bend very easily and tend to block the nozzle due to their physical properties.

We have listed some very simple methods which can be applied on both normal filaments and flexible filaments for drying them.

In The Blog:-

- How To Find Your Filament Needs Drying

- Observe Changes

- Stringing

- Inconsistent Extrusion

- Blockage of Nozzle

- Reasons To Dry Flexible Filament

- Methods To Dry Flexible Filament

- Storing Of Dry Filament

- FAQ – Drying Filament

- Conslusion

How to Find if Your Filament Needs Drying?

It is necessary to determine if your filament needs drying or not. Follow below mentioned 3 ways to check it before drying the flexible filament.

Observe Changes

First, heat the nozzle to a suitable temperature and release 100mm of filament. If you can hear a sizzling sound, small pops, or observe some steam being released near the nozzle during this process, then your filament requires to be dried.

The reason behind all these noises is that the water contained or trapped in the filament quickly changes into vapors during extrusion and can cause problems during printing.

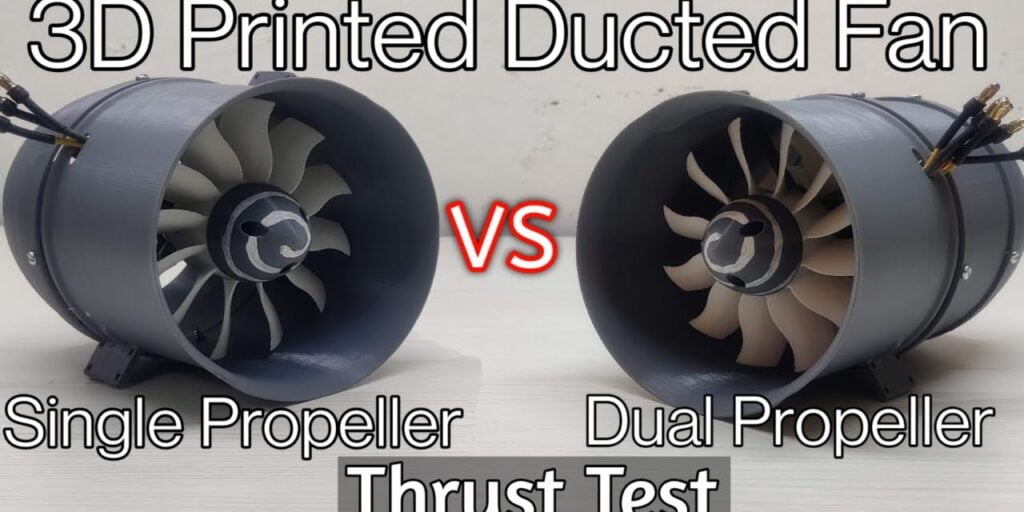

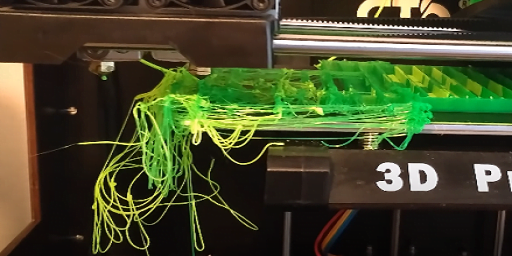

Stringing

While printing, a number of the tiny strings of plastic are left behind on a 3D printed model. It happens when the plastic oozes out of the nozzle while the extruder moves to a new location.

Mostly, stringing is the sign that your filament needs to be dried, so after the heating/drying process, stringing issues should be much reduced or even diminished.

Inconsistent Extrusion

Inconsistent extrusion with improperly aligned layers is another way of detecting that filament has absorbed some moisture. Mostly when filament absorbs moisture, it does not absorb moisture regularly, and some parts of filament have more moisture than others. When that water is released during extrusion, inside the nozzle, pressure increases moderately, due to which printing will not look as good.

Blockage Of Nozzle

Clogging means the blockage of the nozzle or extruder due to any of the given reasons i.e. over extrusion, moisture in the filament, clogging due to unwanted particles, etc.

Here we will focus on blockage due to moisture, when the filament is heated while extrusion the moisture present in the filament vaporizes and makes the filament increase in size which causes the blockage of the nozzle very easily.

Reason to Dry Flexible Filament

A tiny amount of moisture in a material can harm:

- The model quality-air bubble may come out on printout walls.

- A high porosity-material structure that has soaked up moisture after printing may be “foamed.” Many pores form when the filament is released from the nozzle.

- Moisture also affects the mechanical parameters of the print.

So, it is imperative to dry the flexible filament to ward off these problems.

Solution of How To Dry Flexible Filament

The key parameter to obtain the desired properties of printed parts is the actual heating of the material before printing.

To pull out unnecessary moisture from the material, it is compulsory:

- Place spool in the suitable device or place which could block outer moisture.

- Temperature and time at which heating operation should be achieved.

- Remove and place it in an airtight box after use or drying process.

Temperature range for heating material after removing them from the box/container are:

- PA6-material that requires to be heated at 85oC for 24 hours.

- Nylon 680-material that need to be heated at 70-80oC for 8 hours.

- Policymaker-material that requires to be heated at 120oC for 24 hours.

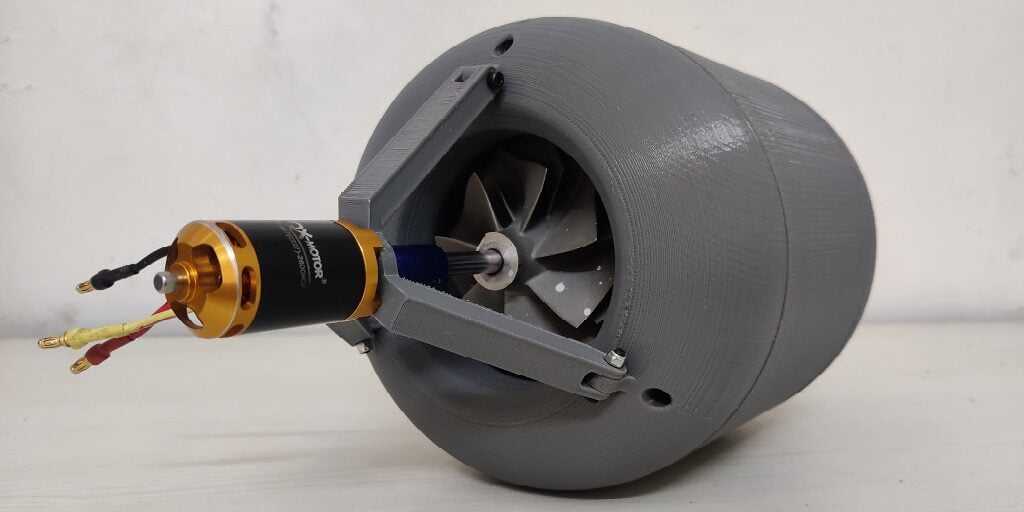

Methods to Dry Flexible Filament

Drying your filament could be a better solution for improving your print quality. First, it’s salient to dispel a common myth. We cannot correctly dry flexible filament out by storing it in an airtight box with desiccant. It is highly recommended only when not using a spool. Now let’s discuss two important solutions of how to dry flexible filament.

Use an Oven.

Using an oven is the simplest and most efficient way of drying filament. It is simple to overheat your filament, creating gas from the plastic. These gasses can be dangerous to inhale. So heating operations can be done with caution. Convection ovens work very well as they continuously circulate hot air around the spool.

This is only possible if you have an oven that permits suitable temperature control. The oven thermostat should be correct before putting filament inside the oven. There is a crucial parameter to know before baking your filament. You must preheat your oven and permit it to reach the set temperature before putting the filament in.

To completely remove any chance of melting/fusing filament during drying, use printDry, a specifically designed system to remove moisture from the filament.

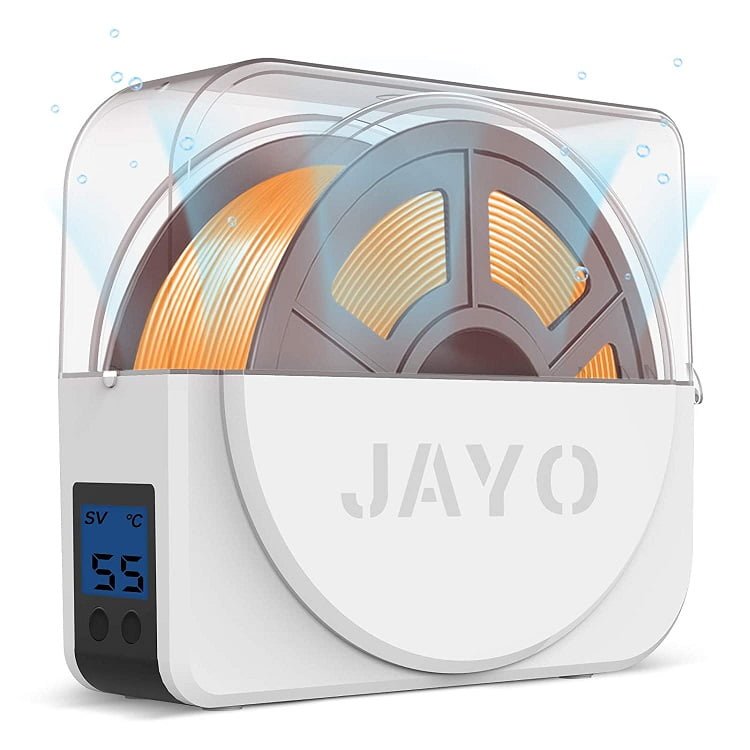

Filament Dryer

Filament dryers are a bit expensive, considering that only a single spool can be dried at a time. Still, it’s an excellent way to print often with Nylon or PETG because filament can be directly fed into the printer from the filament dryer.

One of the best Filament Dryer for all types of filaments is from Dry Box.

Temperature for Drying Filament

Temperature range for heating material after removing them from the box/container.

| Filament | Remarks |

|---|---|

| PA6 | These materials require to be heated at 85oC for 24 hours. |

| Polymaker | It requires to be heated at 120oC for 24 hours. |

| PLA | Dry PLA at a temperature of 40 – 50°C for a minimum of 4 hours if you are heating inside a ventilated oven. |

| PETG | Dry PETG at a temperature of 60-65°C for at least 4 hours. |

| TPU | Thermoplastic polyurethane is the most famous filament for RC enthusiasts because semi-flexible models can be printed through it. Drying TPU at a temperature of 40-50°C for 5 hours is recommended. |

| Nylon | Nylon is one of the common hygroscopic materials you can print. It is suggested to dry your spool before each print because when you take it out from the bag, the filament starts absorbing moisture, drying nylon at a temperature of 80-90°C for at least 12 hours. |

Storage of Dried Filament

After drying, the next step is to store dried filament in a place with low humidity. You can keep it in an enclosed cabinet with some silica bags inside. Another way to store dried filament in sealable bags or buy an airtight plastic box and modify it into an insulated filament holder.

FAQ – Drying Filament

What are the symptoms of a flexible filament that contains moisture?

While 3D printing you will see bubbles, steam, or hear oozing sounds these are all the symptoms of a filament having moisture content higher than normal.

How to easily dry flexible filament?

The most efficient way of drying a flexible filament is by using a filament dryer, they come with predefined settings for each type of filament and give very efficient results.

Conclusion

Mostly the method for drying flexible filament is the same as that of normal filaments. We hope that you have found solutions for your questions in case of further queries please use the comment box.

Thank You.