3D printing is a disruptive manufacturing technology currently being used by many. In order, to fully leverage this technology, it is important to understand how these machines work and how to optimally set up your printer to achieve the desired outcome.

One of the most overlooked aspects of the entire printing process is the nozzle. The nozzle is the last part of the machine that extrudes the melted filament and helps the material to be deposited on the built platform. A good size nozzle is required to achieve a consistent output. The nozzle also determines the print quality, printing time, and even the strength of the print.

Generally, there is a conception that the smaller the nozzle size finer is the layer, and thus the better the quality of print. This is somewhat true but with smaller nozzle diameters there are many other problems that will start if you prefer them.

So, What is the smallest nozzle for 3D Printing that is feasible? The smallest nozzle for 3D printing is a 0.25mm diameter nozzle. This nozzle is the balance of quality and reliance. Yet it sometimes gives some errors about whom we will talk in the post further.

3D PRINTER NOZZLES

While a lot of settings can be controlled through slicer software to get get a fine layered perfect print with excellent quality. Still, nozzle swapping is the fastest and cheapest way to do so.

As already established, nozzles are important and so selecting the right nozzle for your specific printer. This selection must be done with a proper understanding of its advantages and disadvantages. Choosing the right nozzle can go a long way in bettering the overall 3D printing experience.

The important attributes of a 3D printer’s nozzle are its size, material, and type of extruder. With the correct size, you can achieve print qualities on par with SLA 3D printing. The extruder is important because it contains gears that push your filament into the nozzle and if you are using a cheap extruder then it will result in slippage of filament which will disrupt the printing flow.

Once, any one of the layers is disturbed all the layers above it are disturbed and print results in a failure. To prevent this from happening we’ll recommend using BondTech BMG Extruder, you can check it out on amzon.com here. It’s been 3 months since switching to it and we haven’t experienced any slippage or clogging till now.

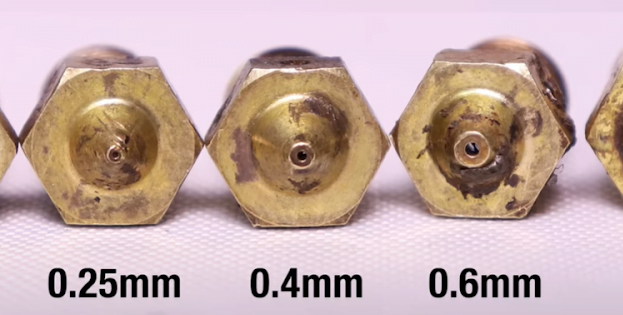

Common Sizes of Nozzle

Nozzle size: 0.1mm

This is the smallest nozzle found on FDM 3D printers. It is not so commonly used and primarily because it is difficult to work with. It is important to understand that a smaller nozzle will deposit less material and also printing time will increase.

But as an advantage, a smaller deposition also means finer details. A 0.1mm nozzle can print incredibly fine features. However, nozzles with this small diameter can be prone to clogging and ensuring proper flow settings.

Nozzle size: 0.25mm

This is a more popular nozzle size for 3D printer users looking to print fine features. The nozzle gives good quality output with a comparatively higher deposition rate than 0.1mm. Not all materials can be 3D printed with nozzles this small.

Nozzle size:0.4mm

This is most commonly used by all users. It is the default size for the print cores. It gives a great balance between good quality and speed of printing. This nozzle lies close to the middle of the nozzle size range and so the print quality is obvious.

Nozzle size:0.8mm

A nozzle of size 0.8mm prints at an impressive speed and the printing can be completed quickly. But as the speed increases, the quality can be reduced as this is not a good selection for parts with fine features. This is a nozzle that every user should have when they want to print fast.

Printing With Smaller Nozzles

There’s a rule of thumb that while 3D printing with a nozzle you should keep layer height to the 30% to 70% diameter range of the nozzle. According to this the 0.4mm is best for printing 0.12mm to 0.28mm layer heights. But, what if you want to have a layer height of 0.1mm or 0.08mm, although a 0.4mm nozzle can do the work it may show uneven extrusion.

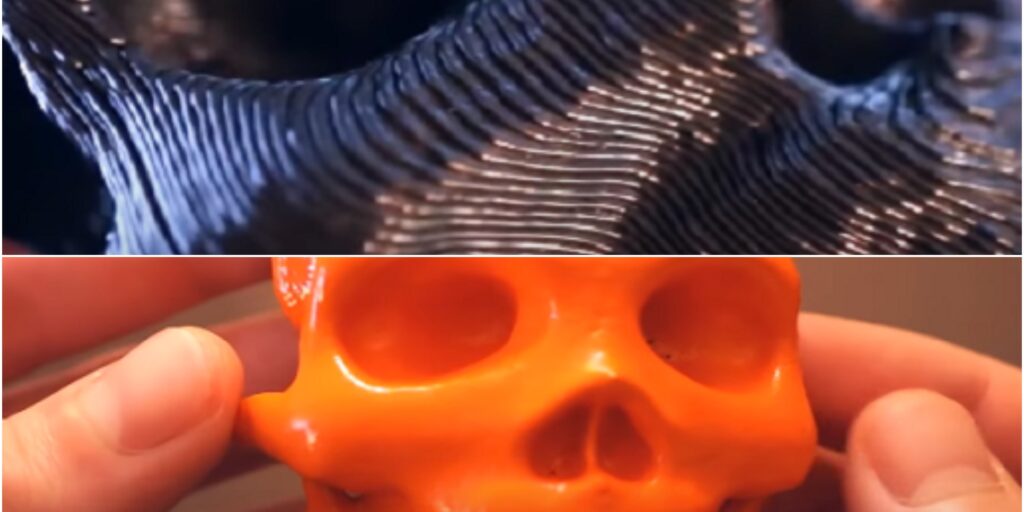

So the logical choice for the 0.08mm layer will be a 0.25mm diameter nozzle. This nozzle can print from 0.075mm to 0.18mm, which is the best in terms of quality. This will produce water-like curves without any gradient difference noticeable. But, it will take a significantly larger amount of time as the number of layers has drastically increased.

The vast majority of prints do not even have the details noticeable to the naked eyes. Superfine font walls and details become visible when using a 0.15mm nozzle diameter that does not exist on larger nozzles. Hence, most of the 3D printing community has been much standardized to around a 0.4 mm nozzle.

Printing Time With Smaller Nozzles

Well, since the layers are about 2.6 times smaller on a 0.15 mm nozzle vs a 0.4 mm nozzle, it will require more than 2.6 times the amount of time required to print a single layer, if using the same printing speed. Printing at half the layer height will double the amount of time required to print all other things. Along with the reduced speed, the requirement of a good gear direct extruder and dialing in the slicer settings can be a turnoff for printing within these nozzles.

WHAT IS THE SMALLEST NOZZLE REQUIRED FOR 3-D PRINTING?

The smallest size of the nozzle required for 3-D printing is 0.1mm, which is found on FDM 3D printers. It is not so commonly used because it is difficult to work with. The smaller nozzle will deposit less material and so, the printing time will increase.

But, as an advantage, a smaller deposition also means that finer details can be captured. A 0.1mm nozzle can print incredibly fine features.

A 0.25mm nozzle is still extremely small FDM 3D printing. It works perfectly for jewelry making. But, it’s faster and easier to print with the 0.15mm. The 0.4 mm nozzle still has plenty of detailed capabilities and tidy enough tolerances. For not-so-detailed prints, 0.6mm nozzles save a lot of time for printing.

Larger the nozzle, the faster the print, and the smaller the nozzle finer the quality print.

Nozzle FAQ’s

How do I choose a nozzle size?

The correct nozzle height is measured from the nozzle to the target, which may be the top of the ground, growing canopy, or stubble. Use 110-degree nozzles when booms are less than 30 inches high with 30-inch nozzle spacing; use 80-degree nozzles when the booms are higher.

Which nozzle size is the best?

That’s up to you to decide. It’ll come down to the array of printing materials you use and whether you’re more willing to compromise on quality or speed. If you want high quality go with a 0.25mm diameter nozzle, but if you want speed and there are no fine layers in your design then you can opt for a 0.6mm diameter nozzle.

Are 3D printer nozzles standard?

The absolute standard in 3D printers today is the 0.4-mm nozzle, which is found in almost all popular machines. This diameter provides a great balance between speed and precision.

CONCLUSION

We believe you will now be able to effectively choose between the different types of nozzles available, and understand why to choose a specific one. There is not one perfect nozzle but instead, the best option for a given application or print based on the detailed requirements, time available for printing, and the material selected.

If you have any questions about how to select the best nozzle for your application, feel free to use the comment box.

THANK YOU.