Adding joints in any design allows to perform movements and also increases the area of uses or utilities. Currently, there are various types of joint mechanisms and it is our responsibility to choose the correct one for our application from different types of 3d printed joints. In FDM 3d printer we can create nice and robust working joints in 3d model in a single print. All you have to do is follow the given steps in the blog.

What are the different types of3D printer Joints? In 3d printed models mostly people use Interlocking joints and snap-fit joints. Both types of joints have different applications and perform well if we use them in the correct place with the correct geometry. In this blog, you can learn how to print joints with an FDM printer, and we will compare available 3d printing technology for best performance in 3D printing joints.

Why do we need to use joints instead screw?

Using inbuilt joints instead screw decrease the weight of the assembly. Joints make your assembly less time-consuming. It has some cons i.e. if you need to disassemble and assemble your model frequently your 3D printed joint starts to wear out. So it is advised to keep this thing in mind before finalizing any type of 3D joint in your print.

Types of 3d Printed Joints

In the 3D printing industry, we see a vast variety of joints but mostly two types of joints used in 3d printing.

- Interlocking Joints

- Snap-Fit Joints

Inter Locking Joints

Interlocking joints are used whenever we have to join two objects which do not have any moment. Interlocking joints do not allow moment except in one axis or direction. These joints are not removable but in some cases, we can add a removing mechanism. In these one object fit into another object via a slot and use a threaded surface in both objects to fit in.

Snap-Fit Joints

These joints are of multiple types, each of them is used for various applications. We can connect parts together rapidly with snap-Fit joints. For a snap-Fit joint, there is a head, hook, or stud-type design in one object, and the second object consists of an undercut or hole with some geometric design for smooth operation in connecting phase.

After connecting the operation hook back to its normal position from the stress position. The separation of these depends on the design of the hook and undercut.

Types of Snap-Fit Joints

These joints have a wide variety of designs. Also, these joints are used in plastic material. Here are some different types of Snap-Fit joints;-

- Cantilever Snap Joint

- Annular Snap Joint

- Ball and Socket Joint

- Hing-Snap Fit Pivots

Cantilever Snap Joint

In Cantilever Snap-Fit joint one part has a hook or bead which is protrusion via beam from the body of the part and the second part has a hole with some slope for the easy connecting process of two-part. When we connect two-part with a cantilever snap-fit joint the hook deflects our brand a little bit and slides down in the hole, when the hook goes past the hole then it comes back to its normal position and locks both parts.

Cantilever snap-fit joint is very common and we can find this in multiple items because making them is very economical. Also, it is very easy to disassemble and assemble the cantilever snap-fit joint.

Annular Snap Joint

An annular snap joint is used where we need to rotate one part on another part in one axis. One model in the annular snap joint has a circular ring on the outer body and the second model has a ring inside its body. So when we press both printed model on each other the second model slide over the first model outer ring and lock both parts in their place.

It is important that the model which has an inner circular ring has the flexibility to slide over the first ring. Also, we can achieve a waterproof joint with an Annular snap-fit joint. Commonly we see an annular joint between the pen and its cap.

Ball And Socket Joint

Ball and Socket joint allow parts to bend and rotate in multiple directions. when we slice the design which has ball and socket joint so it is important that if we scale down the model then it’s the clearance between ball and socket also decreases so keep this in mind while designing and printing this joint.

Hinge-Snap-Fit Pivot

The hinge snap-fit joint has a hinge bar which has a slice between the structure and this slice end a little above before the bar end. While second part has a circular hole. When we push the hinge on a circular hole then the hinge compress because of outer force and when it passes the hole the hinge return to its original shape and fits tightly.

Designing and Printing Tips for 3d Printed Joints

When you design joints in your 3d model it is necessary that you know which type of condition part suffers, where your joints have the most stress during the operational time. Also, add some additional support to the joint to smooth operation. Also, use a Topology-based design for equal stress distribution on parts. In a movable joint make sure it has enough clearance to move freely.

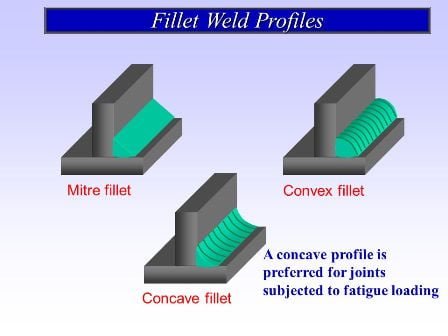

1. Fillets and Chamfers

We design joint solid because we don’t want that they break under load conditions but it is also necessary that they have some flexibility so they work perfectly for their designed life. In 3d printing when a model has a joint so make sure its hook has fillets or chamfers as it will provide more support and strength.

In Fillets, there sharp flat edge of the joint is replaced with the round edge which helps in equal separation of the force. While in chamfers sharp slat edge is replaced with multiple small squares which create a small rounded edge for the long life of the joint.

2. Clearence

Every movable joint need some little space between the joints to move freely, this space is called clearance space. In Ball-Socket Joint you need to create an outer socket with a 0.3 mm increase in diameter so they can fit and move easily also different materials need different clearance for joints but this is not easy. Most of the time it works but some time you need to perform trial and error for finding the perfect value for your joint. So for convenience and saving cost in trial and error, we only need to print joint parts only from the entire model to test the joint performance.

After finding the perfect value for the clearance you can print the entire model.

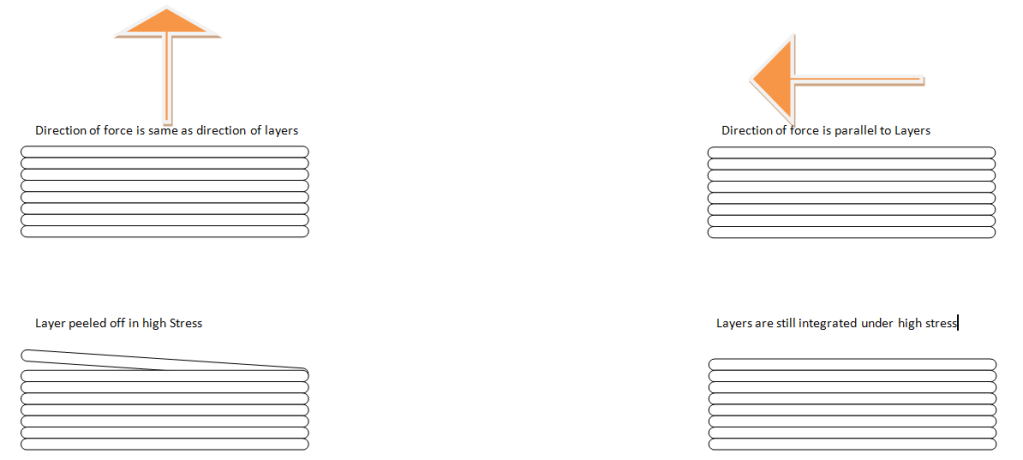

3. Slicing The 3d Printed Joint

In slicing you know if a thing printed parallel to the layer or applied force is parallel to layers then your part can within high load conditions. While you are slicing the model keep this condition in mind.

Note:- Whenever you slice a joint to make sure the joint does not have any overhang because overhang makes the surface rough so if your joint has the ability to move then due to rough it is stuck during working time.

4. Selection Of Material For 3D Printing Joints

The Joint has to suffer a lot of force so it is necessary that your joint does not fail while working. Choosing the correct material for a joint also changes its robustness, if you use very flexible material then your joint does not work properly and if you use very hard material then your joint become brittle. Most makers use ABS filament for 3d printing joints because it has a balanced amount of flexibility and rigidity. Also, ABS filament is cheap and available easily.

5. Add Lugs to Model

When we joint two object some time we notice that one part have some pattern while the other part has a hole of these patterns and when we connect both parts these pattern act as guiding structure and also give stability to the joint because joints are enough rigid that make your object strong.

Test Your 3d Printed Joints

When you do not make a decision that which type of joint you have to use or what type of material it has then it is good to test all your assumption in the test model joint. You only need to print only joint area from your model with your assumption parameter and test to find out which is best for your project.

Best 3D Printing Technologies For Printing Joints

If we want to make different types 3d printed joints end-user ready which is used multiple times without breaking the joint then we can use SLS and Material Jetting 3d printing technologies. Yes, we can use FDM 3d printing also we can use resin printing but it is brittle and broke after some use so we need very durable resin but when it comes to end user ready then SLS and Material Jetting 3d printing are best for joints.

With SLS printing we make functional snap-fit joints that can be open and closed multiple times and for more robustness, we use SLS Nylon. In Material Jetting with high resolution and durable resin and digital ABS are very good for creating functional Joints.

FAQ on Types Of 3D Printed Joints

The 3D printed joints are mainly divided into 2 types i.e. Interlocking joints and Snap-Fit Joints.

Snap-Fit joints are mainly of four types i.e. Cantilever, Annular, Ball and Socket, and Hinge Snap-fit pivots.

There are various things that we need to keep in mind while 3D printing joints some most important of them are fillet and chamfers, clearance, slicing, material selection, etc.

Conclusion

We hope that this detailed post on “Types Of 3D Printed Joints” has helped to clear your doubts related to the topic, still, if you have any doubts ask them in the comment section below.

Thank You.