Choosing between SLA and FDM will always be a tough task. If we divide the properties of each printer into categories then we are sure that they will have a tie as one is better than the other in some way or another. But, despite their advantages and disadvantages, we should select SLA or FDM according to our needs and ease. Thus to make the selection procedure much easier we have compared both SLA Printing and FDM printing in various categories in a very simple way.

What is the major difference between SLA printing and FDM printing? The major notable difference that most of us ignore is the ability of FDM printers to print with multiple filaments (raw material) in a single printing operation, this can be used to print a single part in different colors and many other uses. Although, there are many other major differences between FDM and SLA, and in some of them, SLA is far better than FDM like print quality, detailing, etc. Thus, we have discussed them below topic by topic.

FDM Printing VS SLA Printing | Categories

- Basics

- Multicolor Printing

- Surface Finish

- Ease of Printing

- Cost

- Working Mechanics

- Common Maintenance Issues

- Strength

- Portability

- Detailing

- Speed

- Safety

- Odor

SLA Printing VS FDM Printing: Basics

SLA Printing:

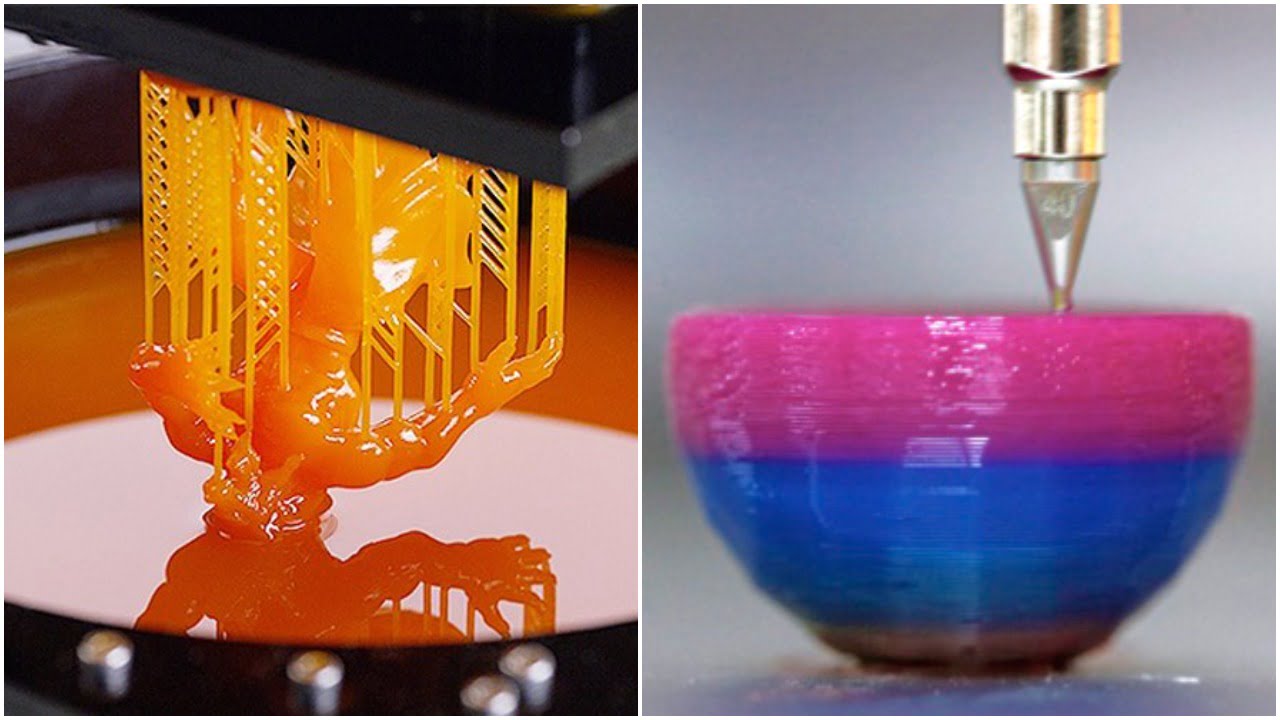

The term SLA stands for Stereolithography and was invented in the 1980s. It uses the concept of the photopolymerization process to harden the resin(raw material) with the help of UV light. A UV light is used to cure or harden the resin where required, whilst a platform moves the object being made upwards after each new layer is cured.

This simple yet effective process makes SLA printing one of the most successful 3D printing options in terms of material finish and printing speed, although it has some of its drawbacks which we will discuss one-by-one below.

FDM Printing:

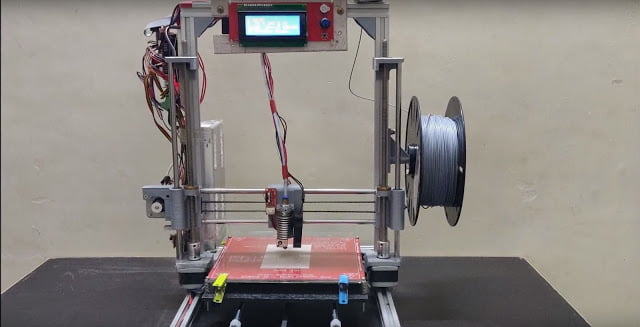

FDM stands for Fused Deposition Modelling and it’s also known as Fused Filament Fabrication (FFF). It is one of the most popular 3D printing methods mainly used by hobbyists and for small-scale 3D printing requirements. It is very user-friendly and also environment friendly as the main raw material used in FDM is PLA which is biodegradable and recyclable.

The main mechanism used in FDM printing is melting the filament (raw material) and then adding it layer by layer to the predefined set of coordinates. The melted filament stick with each other and gives us a sturdy 3D print. FDM printing also has some advantages and disadvantages over SLA printing which we will discuss in detail in the post further.

We have divided SLA printing VS FDM printing is several categories so you can have a clear idea of how they are in comparison with each other. So, without further ado let’s dive right into the comparison tables.

Multicolor Prints

This is the topic that many peoples tend to forget or ignore while comparing SLA printing and FDM printing. Multicolor print means that 3D models with 2 or more different colors.

| SLA Printing | FDM Printing |

|---|---|

| The main concept in an SLA printer is to cure the resin in the tank with UV lights, for this you need to fill up the tank with your desired kind and color of resin. But, you can’t swap them in between prints as emptying and filling a resin tank with different colors of resins will require you to stop the printing procedure and that will result in print failure. So we can say that in SLA printing multicolor printing is not possible. | FDM printers use filaments as their raw material which are solid or semi-solid (flexible) in nature and are easily swappable. Also, currently, there are multi extruder FDM 3D printers in the market that can be used to print with two or more types of filaments at a time. You can also make a DIY Dual extruder for FDM 3D printers. |

Surface Finish

While 3d printing models for show purpose or for representing it in meetings surface finish is very necessary, you don’t want to have a bad impression in front of your clients.

| SLA Printing | FDM Printing |

|---|---|

| In this, very thin layers of resin are UV treated at a time i.e. 25 microns to 100 microns thus, they have a significantly better surface finish than FDM printers. | They don’t provide a very smooth finish as there is the issue of layer height which starts from 100 microns and layer adhesion which makes them not even thus, there is generally a rough surface finish. Although you can use post-processing methods in FDM to have a better surface finish. |

Ease of Printing

By ease of printing, we mean the simplicity through which you can print any simple or complex 3D model without having trouble deciding the number of supports and other things.

| SLA Printing | FDM Printing |

|---|---|

| There is a need for predefined internal geometry for their working operations. Through SLA printing you can print complex patterns with the accuracy of both internal and external geometry. | This one cannot print too many complex patterns with accuracy. In this, with too much minute 3d printing it becomes difficult for layers to keep things separate they may entangle with each other as their layer height is not small like SLA printers. |

Cost

Cost is one of the most important factors of owning and working with a 3D printer one cannot ignore this. The factor of cost is directly related to the number of materials or parts you need to handle in the given 3D printer.

| SLA Printing | FDM Printing |

|---|---|

| The use of LCD and innovation in technology has made SLA 3d printing also cheaper, but their price is not yet anywhere near FDM printers. The SLA printers cost also depends upon their resolution, but there are “n” numbers of issues which makes them very costly like, the raw material used in SLA printers i.e. resin itself is very costly i.e. around $120 for 1 Kg, the processing of UV curing needs a completely different mechanism and set up for working which is costly. Also, the isopropyl alcohol which is been used in post-curing also leads to increases in the cost. | FDM printers are one of the most affordable and cheapest 3D printers in the 3D printing industry right now. The basic raw material that is used in this is the filament which costs around $20 – $40 for Kg of the spool. Also in FDM printers, there is no need for post-curing processes, thus it saves our purchasing and maintenance costs in many ways. |

Working Mechanics

Working mechanics of a 3D printer give us an idea of what we will be dealing with in case of any requirement of maintenance. This also tells us about the finishing and strength (we will talk about it in the next heading) of the 3d print.

| SLA Printing | FDM Printing |

|---|---|

| In this, a UV light is used to cure or harden the resin wherever required, whilst a platform moves the object being made upwards after each new layer is cured. This process is repeated layer by layer and our 3D print is obtained. The minimum layer height in SLA printing is 25 microns or 0.025mm which helps us to obtain a very smooth finished surface and sturdy prints. | In FDM printing the 3d model is made by melting the PLA filament and then making the desired layer one by one. The smallest layer height which can be achieved by FDM printers is currently 0.1mm or 100 microns, which is much larger than SLA printers. This difference in layer height makes the FDM prints much rougher and fragile than SLA prints. |

Common Maintenance Issues

| SLA Printing | FDM Printing |

|---|---|

| The main problem is the post-curing of 3d printed parts which requires extra work and time. Isopropyl alcohol is also required for smoothing and finishing purposes. All these extra products mean the chances of them requiring fixing and diagnosis are much higher. Common things that require regular checkups are cleaning & swapping of resin tank, removal of stuck cured resin from the bottom, etc. | The basic concern is “nozzle clogging” i.e., when the filament is oozing out from the extruder it is hot, and as there is continuous layering through the extruder, sometimes the raw material gets cool down and leads to clogging of the extruder pore which doesn’t allow the further feeding. This is the most frequent maintenance problem in FDM printers. Other common problems include wiring problems, roller jamming, moist filament, etc. |

Strength

Strength is a very important factor while deciding on going with SLA printing or FDM printing. The strength is the most required factor while performing prototyping.

| SLA Printing | FDM Printing |

|---|---|

| SLA prototypes are more preferred over FDM because they have much lower layer heights which provide extra strength to the models. Also due to UV laser curing and post-curing methods make it more durable than FDM prints. | FDM prototypes are fragile in comparison to SLA prints as in FDM printing layer height is much greater than SLA prints and layer adhesion is only due to the heating of the filament which is not much durable. Also, they are most susceptible to failure in the plane perpendicular to the layer plane. |

Portability

This criterion is important if your work requires you to carry your 3D printer from place to place for example if you are a professor and you have exhibitions in different schools and colleges.

| SLA Printing | FDM Printing |

|---|---|

| Most of the parts of SLA printers are combined and fixed with each other thus you simply can’t unscrew them and dismantle them for transportation. You will need to carry the printer as a whole. Also, the mechanism is a little bit complex than FDM printers hence you can’t try to use your “skills” on it. | On the contrary, FDM printers are pretty easy to understand and could be easily unscrewed and separated into sub-parts that can be reconnected on reaching the destination. One can also learn the whole working of FDM printers in few days in great depth. You can also build your own DIY FDM printer at your home for under $150 or less. |

Detailing

Detailing is much required in case of presentation for your clients or anywhere. Generally, it is directly related to layer height so you have got the idea of who is better in this category.

| SLA Printing | FDM Printing |

|---|---|

| SLA printers have very low layer height i.e. 25 microns and also their layer adhesion is done due to the UV-powered laser beams which provide incomparable results. Thus, 3D prints made from resin printers have very detailing. You can also print miniatures around the size of your fingernail with very ease. | The layer height of FDM printers starts from 100 microns and hence they don’t have much detailing in their 3D prints. Also, layer adhesion is simply due to the heating of the filament and sticking with each other which gives a layered texture to the print. |

Speed

When you are printing a big 3D model or prototype then it could take hours or days depending upon the volume of the print. But for the same model, both SLA and FDM printers have a drastic difference in their printing times. Also, print speed and print quality are inversely related to each other so if you will increase the printing speed the time will obviously decrease but then you have to compromise with the printing quality.

| SLA Printing | FDM Printing |

|---|---|

| SLA printers use layer curing which is pretty fast when compared to FDM printers. Also due to the UV curing layer adhesion is fast. The maximum claimed print speed by SLA printer is 720mm/hr. | FDM printers lay layers by heating the filament and then moving over the layer length by length which makes it a little bit time taking, another factor that adds up to the process is layer adhesion which also requires some time. Although you can speed up the process the chances of print failure will increase and also the printing quality will drastically decrease. The maximum claimed print speed by FDM printer is 500mm/hr which is less than SLA 3D printers. |

Safety

When using 3D printers at home or a place where your pets and little ones could reach them easily you have to be concerned about safety.

| SLA Printing | FDM Printing |

|---|---|

| Nowadays most of the SLA printers come with enclosures and hence they are pretty safe for your little ones and pets. But when it comes to handling resin and post-curing chemicals SLA printers are quite harmful. Being in the constant presence of burning fumes of resin and isopropyl alcohol (post-curing agent) could cause irritation and other problems. Also, resins are known to be bad for your skin in case of long exposures, so always use gloves while handling resin. So, you need to be careful while working SLA printers. | FDM printers have few major components that we need to look out for. First is the hotend and heatbed, they are used to melt the filament and heat the printing bed respectively thus, they generally operate between 110oC to 160oC. There are other mechanical and electrical components that can easily cause injury if caught upon. Always use enclosure if your printer is in reach of kids and pets, you can easily build a 3D printer enclosure yourself for less than $50. |

Odor

While working with 3D printers in a closed environment with no means of ventilation odor could become a big headache. Well, our advice will be to always use 3D printers in a well-ventilated area.

| SLA Printing | FDM Printing |

|---|---|

| IN this the UV curing of resin causes the release of irritants and pollutants and they could enter your body and cause problems. | The only odor produced while working with the FDM printer is the burning smell of filament which is generated while melting filament. If you are using PLA as filament then it is mostly non-toxic as they are made from lactide which is a non-toxic compound. But using ABS as filament you have to be careful as their fumes could cause irritation and produces an unpleasant plastic-burning smell. |

FAQ on SLA Printing VS FDM Printing

The printing speed claimed by SLA 3D printers is 720mm/hr, and that by FDM 3D printers is 500mm/hr. Although FDM printers could reach more speed, then print quality will be very bad.

Both SLA and FDM printers use a fundamentally different type of raw material, SLA printers use resin as raw material which costs around $120 per Kg and FDM printers use filaments which cost around $30 per Kg.

Conclusion

We hope that everything is made clear to you through this post on SLA printing VS FDM printing if you want to ask anything related to the topic then please use the comment box below.

Thank You.