3D printer nozzle assembly and changing can be complicated. But not if you break it down into small chunks that are easy to understand. In this article, we will go over the things you need for a successful 3D printer nozzle assembly. There are many types of nozzles that are generally used in the 3D printing industry, some very common of them are brass nozzle, stainless steel nozzle, copper nozzle, etc.

We will discuss from the start to end about the brass nozzle which is used by most of us, although the assembly process is similar for most of the 3D printer nozzle types they are slightly wary. We’ll start with the workbench. Once you have a 3D printer, the first thing you’ll need to do is set it up by placing the print head and extruder assembly on a table. Then, place the tool holders to be positioned correctly and properly nested. Making sure all the supports are in place helps you produce better accurate prints, reducing the number of failed prints.

Next, you’ll need to have a flat work surface. If there isn’t one already, place it underneath your printer. For example, remove the platform if you’re using a RepRap printer sitting on a powered rotating platform. For a delta printer, make sure the base is flat. A heated bed isn’t required but can help your prints stick better.

Before you start printing with a nozzle, you should adjust it to be ready to use and smoothly extrude material. To get started, you need the right software settings. Now let’s get in more details.

What is 3D printer nozzle assembly?

3D printing is the future of engineering and design because it allows you to produce almost any item you want in limited quantities. While 3D printing holds a lot of potentials, there’s still a long way to go. Like any other manufacturing process, 3D printing requires specialized machinery and the right software and work environment.

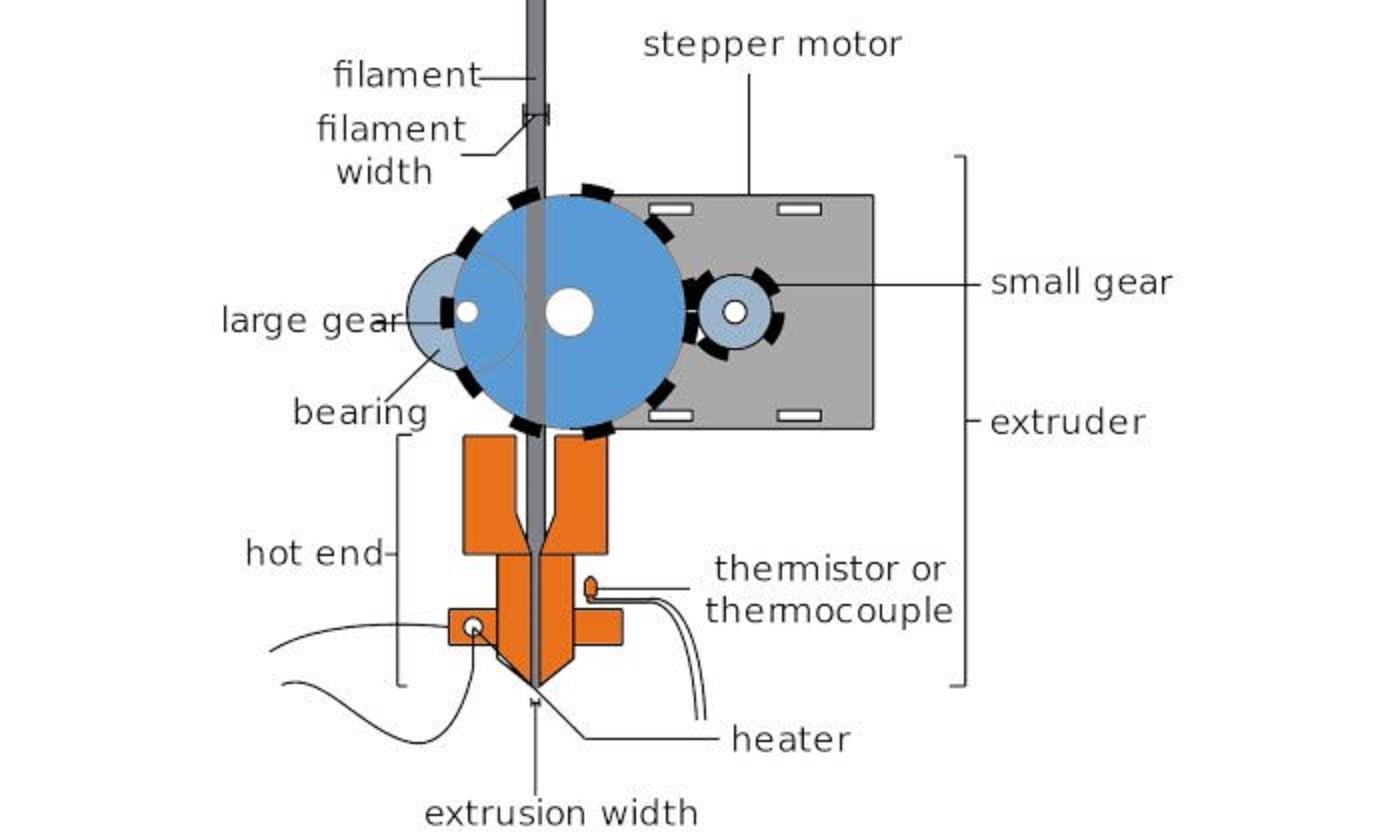

The nozzle is an important element of your 3D printer. As the output from the print head travels through the hot extruder, it sprays thread-like lines of material layer by layer. The nozzle is responsible for ensuring that each layer of thread is printed correctly, with smooth transitions between layers.

What to know about 3D printer nozzle assembly?

It’s important to understand how to assemble the nozzle assembly. The nozzle assembly is a piece you can assemble with the rest of the printer itself. You need to ensure that everything is assembled properly and that the parts are not just put on and taken off the printer.

- The nozzle guides and push down on the printing surface and compress it flat against the base plate so that when we extrude filament out of the nozzle, we get a nice and even deposit of material across our print surface.

- The Interchangeable Thermal Print Head is an extra 3rd nozzle for a 3D printer. It’s like an assembly that you attach to your printer’s hot end. The main difference is that the “Nozzle” of this assembly is designed to work with a specific type of filament.

- This nozzle differs from the Stock NOZZLE in that it has an “Easy to Clean” inlet for the filament. It also has an “SDC” feeder port for filament distribution “SDC,” which will allow you to print with more than one color.

- At the bottom of the guide is the smaller bar that is spring-loaded; inserting a cleaning filament through the hole unloads and resets it, clearing any jamming filament from the nozzle. This is a handy feature, and I recommend purchasing one with this nozzle upgrade.

- Assemble these parts from a barrier along the edge of your print bed to stop any extra material from oozing out of the side of your nozzle.

- The nozzle that comes with this assembly has a slightly higher tolerance for PLA than the stock nozzle, which allows you to print slightly faster at higher temperatures. It also works well with PETG and PC but takes a lot of tinkering to work well with ABS.

- It is not compatible with the aluminum beds that are popular on printers.

- The steel nozzle core is harder to find than the aluminum one and can be replaced by producing your own at home or purchasing a nozzle core from another source.

- PLA of any type is compatible with this nozzle. I have successfully printed with ABS, PDMS, PETG, and PC; however, I wouldn’t recommend trying it out if you haven’t tried printing with ABS before; it’s more hassle than worth it.

- You will need a printable bed with a layer height between 1.5mm and 2mm. If you don’t have one, or it’s too small, try using the printer simulator in slic3r or Cura to test before buying the rest of your parts.

- Use PLA filament, ABS, and similar materials as they jam very easily with this nozzle for best results.

- This upgrade has various versions, with different nozzle attachments for slightly different purposes.

- Make sure you get the correct hotend for your printer; there are various them to choose from, depending on your requirements and budget.

Ultimate Guide To The 3D Printer Nozzle assembly

Start by having the extruder release the filament. Then try to get out as much as possible. It’s the best practice to do a cold pull when you are finished using the nozzle. This will make it ready for your subsequent use.

- Heat your hot end to 220 oC and use an E3D-style hybrid or all-metal hot lot. I recommend starting by loosening the screws on the heat block. This will give it some room to wiggle and prevent it from breaking.

The thing to remember: Remember, righty tightly, lefty loosey, and this shouldn’t require much force at all.

- Grip the heater block and unscrew the nozzle. Make sure not to put any extra force on the heat break by holding it straight. Clean off the end of the nozzle as you pull it out. If your particular model requires a PTFE tube, Now’s a good time to check that it’s still in place. Ensure it is not deformed or mangled.

- If you’re going to disassemble your mower’s engine, start by applying a bit of anti-seize to the threading. Screw-in the nozzle without tightening it down but instead, make sure to leave a gap of half a millimeter to the block.

- Start by applying anti-seize on the threading of your new nozzle before reassembling it. Start by using anti-seize on the threading of your new nozzle before reassembling it. If you tighten the heater block and heat break, you can feel them snug against the nozzle.

- Finally, screw the nozzle all the way in and double-check that the gap between the nozzle and the block is still there. To tighten up the machine, heat the hotend a little more – around 250 degrees should be plenty, but if your hotend can go to 300 degrees, that’s even better.

- Tightening the pieces after they’ve been heated up ensures that they won’t loosen over time due to thermal expansion. The torque needed to use this nozzle isn’t intense.

- To compare, just using two fingers on this tool is plenty, about one Newton meter. The heater block is the first piece you should tighten. Then, torque the rest of the assembly together.

The process for installing a hot end could differ depending on how it’s built. But this guide gave you a good idea of where to be careful.

FAQ on 3D Printer Nozzle Assembly

A 3D printer extruder is composed of multiple parts, some important of them are stepper motor, heater, nozzle, thermistor, etc.

Final Thoughts

The design of nozzle assembly would be an excellent place to start when working with kids. With a basic understanding of the 3D printer and how to assemble it, you can easily build this nozzle assembly. And if you’re learning something new, then a guide should help you familiarize yourself with the process.