Hey guys, there are several and several kinds of materials available in the market, used in the field of 3D printing. We have discussed the Best PLA filament already. So, now we would be looking into what the PETG filament is and how to use them.

PETG stands for Polyethylene Terephthalate (Glycolized). It is a glycol-modified genre of Polyethylene Terephthalate (PET). Let’s have a deep discussion over PETG, its properties, and how it should be used.

What is PETG Filament:

PETG filament is a thermoplastic polymer, widely used for manufacturing stuff with both the simplicity of PLA filaments and the strength of ABS. They are amorphous in nature and are up to 100% recyclable.

The Glycol added to its composition reduces its brittleness and thus its vulnerability. It inherits all the properties of PET like its good impact resistance, dimensional stability, and transparency.

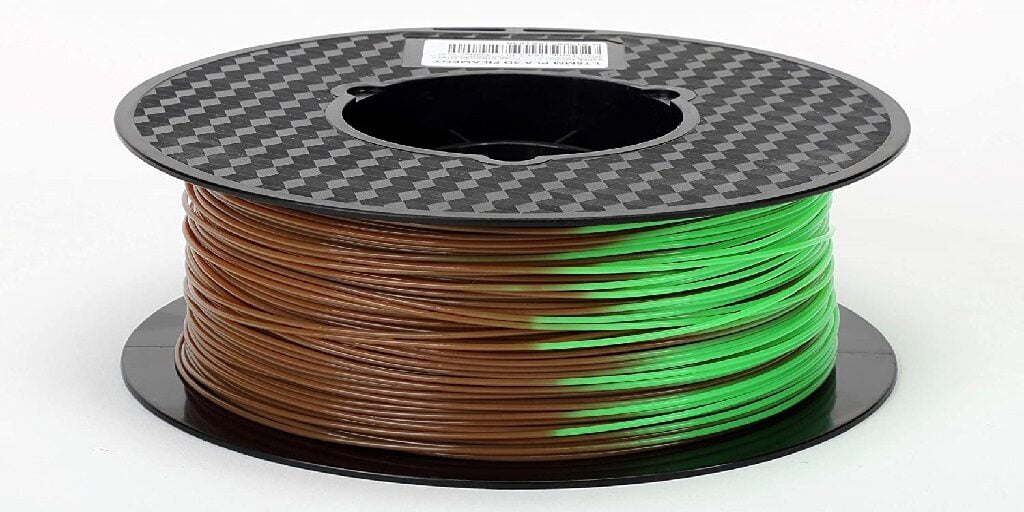

PETG Filament

Properties of PETG Filament:

PETG is a Copolymer due to combined features of PET and Glycol. The Glycol reduces the overheating vulnerability of PET. Some of the major characterstics exhibited by PETG are:

- Hardness: This property is inherited from the PET. PETG is quite hard and thus is enduring.

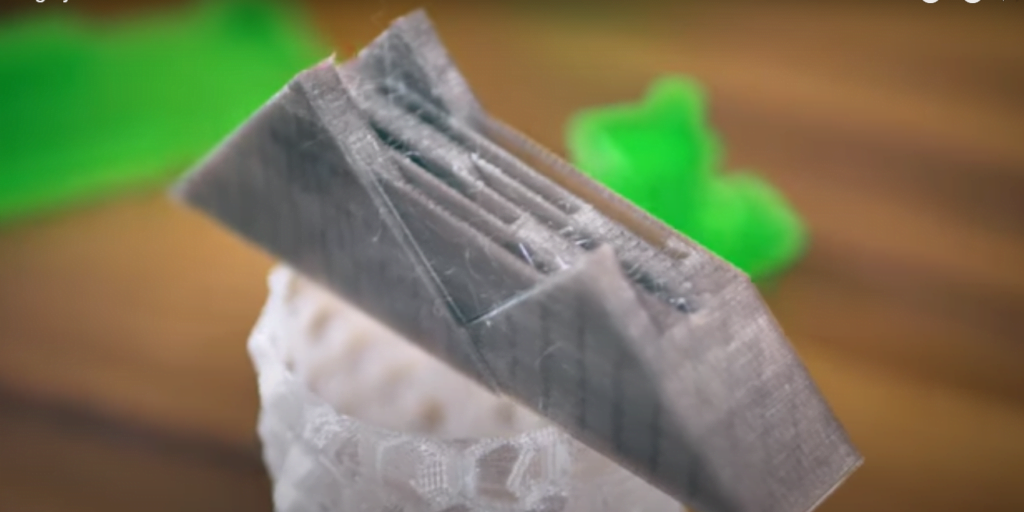

- Transparent: Transparency is also inherited in PETG from PET.

- Ductility.

- Chemical Stability.

- Good thermal stability.

Printing Parameters:

PETG has an extrusion temperature between 220 to 260 degrees Celcius as prescribed by the manufacturing company. One must go with 230 degrees Celcius if no temperature is prescribed.

One should not heat the tray more than 80 degree Celcius. They should use some Additional adhesive over the print bed as the PETG has some sticking problem with bed. As consequence, when separated from print bed, it comes out with thin glass layers.

The printing speed should be around 40 – 60 mm/s. It is more certain to scratches than PLA. It can take moisture so one should be careful by keeping filament in a cool and dry place.

In terms of availability, like other filaments, PETG is available in 1.75 and 2.85 mm diameter.

PETG is often reinforced with carbon fibers, which increases the rigidity of part. Also, they are available in the price range of about $40 – $ 70 for 750 grams of spool each. The Price may vary significantly from brand to brand.

PETG Filament

Hardware Requirement:

- Print Bed: The temperature of the print bed should be between 75-90 °C. Also, a Heated bed is recommended and enclosure is not required at all.

- Extruder: The temperature is 230-260 °C and no special kind of hot end is required.

- Cooling: It might require part cooling Fan. The fan speed should be 20% to 50%.

Pros of PETG:

- PETG are mostly Odourless while printing.

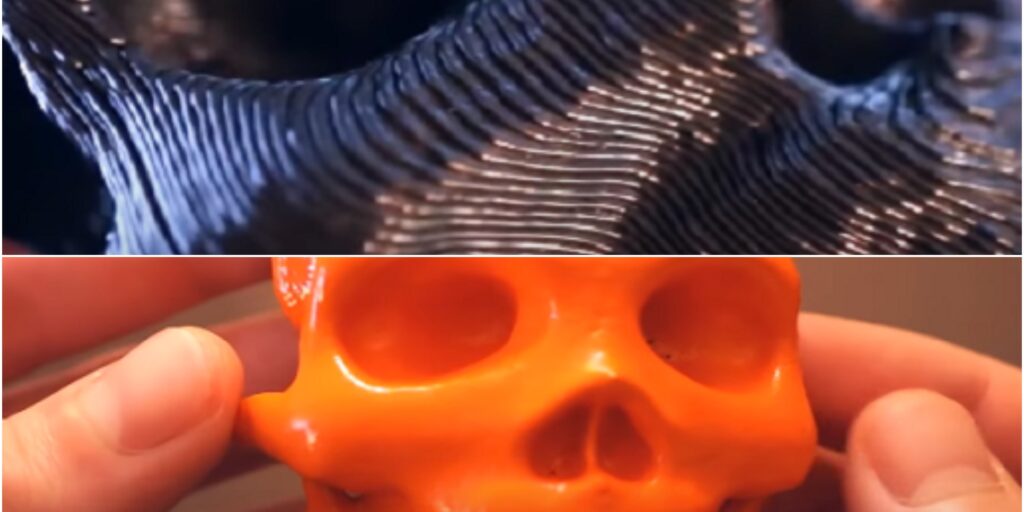

- It has Glossy and Smooth surface finish.

- Adheres well to the bed with neglible warping.

Cons of PETG:

- Produces thin Plastics hairs on the surface from stringing.

- Poor bridging characteristics.

PETG Filament

PETG Filament v/s PLA Filament:

| PETG Filament | PLA Filament |

|---|---|

| 1. PETG filament are way better than PLA filament as they have strength similar to ABS too. | 1. PLA Filaments do not have the strength of ABS. |

| 2. PETG Filaments have their Extruder temperature range between 230 to 260 degrees Celcius. | 2. PLA filaments have their Extruder temperature range between 190 to 230 degrees Celcius, which is way lower than PETG. |

| 3. Gives glossy and smooth final products. | 3. Its products are less glossy and smooth compared to PLA. |

| 4. Its price ranges between $40 to $70 per 750 gram of spool. | 4. Its price ranges between $30 to $60 per 1 Kg of the spool. |

| 5. Have a temperature tolerance of about 65 to 75 degrees Celcius for general filaments. | 5. Have temperature tolerance of about 50 to 60 degrees Celcius for general filaments, which is less as compared to PETG. |

| 6. Heated bed is required for about 60 to 70 degrees Celcius. | 6. No need for any Heated bed. |

| 7. Filament density is higher in PETG. | 7. Filament density is less in PLA as compared to PETG. |

Frequently Asked Questions:

To reduce the hairs on the final print, One might vary the print speed. But, it cannot totally be removed. So, one should use a Hot Air blower to get rid of those plastic hairs on the stuff.

I must say yes, Because They show good properties when it comes to conductivity and also, Prusa uses them for MK3 3D printers too.

Well, no you just cannot directly paint and glue as nothing sticks to it. but with some other ways, you might be able to do so.

PETG Filament

Conclusion:

As we have discussed a lot regarding what PETG is? Its various properties and How is it used for manufacturing the stuff? I got to see that it really prints great stuff with really good properties.

So, I would conclude that if you are wishing to print something smooth, and quite strong, you should go for PETG. But, don’t forget to follow the guidelines as it might result in great loss to you.