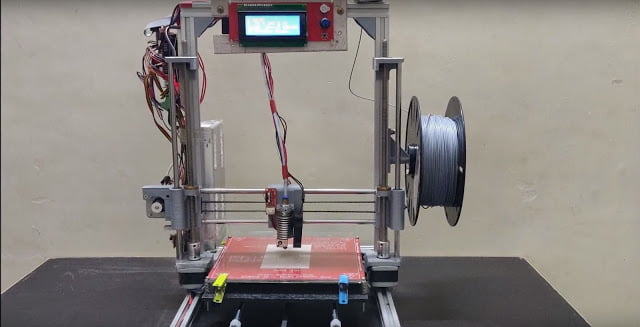

FDM or Fused Deposition Modeling is one of the most common 3D printing technology in use currently. Now, if you are thinking of getting started in the 3D Printing domain, then in some way or another you will face a question i.e. whether I should work with FDM printing technology or go with some other technology?

In this post, we will help you in deciding whether you should go with FDM technology or not. We will give you in-depth details about its advantages and disadvantages because trust us, we have been in that place.

Main Advantages & Disadvantages of FDM 3D Printing

FDM Printers’ cost-to-production ratio is very good, at a minimal cost they can print very large models, that too very effectively. The one main disadvantage of FDM 3D Printing is that with an increase in print volume, their printing quality starts to deteriorate and also the finishing of FDM printers is not of the top level.

Now, there are many other advantages and disadvantages related to FDM printing so keep on reading.

Advantages & Disadvantages of FDM In A Nutshell

| S.No. | Advantages | Disadvantages |

|---|---|---|

| 1. | Budget-Friendly | Rough Surface Finishing |

| 2. | Filament Reusable | Warping is common |

| 3. | Cloud Server Printing | Nozzle Clogging |

| 4. | Less Complex | Longer Printing Time |

| 5. | Easy Ergonomics | Layer Adhesion Problem (Layer Shift) |

| 6. | Variety of Material Choice | Weak in Strength |

| 7. | Easily Portable | Bed Calibration is Needed Frequently |

| 8. | Compact Design |

FDM Printing Advantages In Detail

Budget-Friendly

A nice, pocket-friendly FDM 3D Printer has all the essential requirements and could be easily bought for less than 200 dollars. Some of the most popular FDM printers of world-renowned companies are not expensive.

Their filament (fodder) is also cheap i.e. approximately 18 USD for 1KG of PLA Filament Spool (One of the most common Filaments for FDM printers).

You can also make an FDM printer at home yourself, to know more visit Homemade 3D Printer Under 150 USD

Filament Reusable

Sometimes our FDM printer experiences some errors and our printing gets failed. This causes the filament that was used in printing to be unusable in other printers.

But, in FDM printers as most of the filaments are plastic-based thus they can be reused. They can be easily reshaped in form of the filament by heating and straightening them.

There is various machine that is available to recycle filament very easily.

Less Complex

The overall complexity of an FDM 3D printer is very low. In FDM 3D printers all the steps i.e. designing, slicing, printing, post-curing, etc. are very simple.

FDM printers are one of the most simple 3D printing machines and they are best for someone new in the domain.

Easy Ergonomics

Ergonomics means the connection between humans and machines. Believe me, FDM printers have the most efficient relationship between both. You will not face any difficulty while operating this machine.

It always feels like FDM printers are pointing you to the next step themselves. All the options and steps in printing are super easy.

Variety of Material Choice

Material i.e. Filament used for printing is available in various options. There are more than 9 filament options available to be used as fodder in FDM printing.

Some common of them are PLA, PETG, ABS, PET, TPU, Nylon, and ULTEM.

PLA: (Polylactic Acid) is one of the classic 3d printing filaments in the market. It’s also the most used filament for 3D printing in FDM technology printers. It is also eco-friendly as it is biodegradable.

PETG: (Polyethylene Terephthalate Glycol) It is taken one step ahead of PET by adding Glycol and thus, making it more durable.

ABS: (Acrylonitrile Butadiene Styrene) This filament is made from materials that are available in our day-to-day life like in keyboard caps etc.

PET: (Polyethylene terephthalate) is one of the most versatile filaments with good strength and durability. One main drawback is that it is non-biodegradable and causes environmental pollution as it contains Ethylene in it as a monomer.

Easily Portable

Due to its simple design, its components are easily detachable. This makes it very handy and easily movable from one place to another without any hassle.

You can untighten some screws and voila one component is out, similarly, you can unscrew most of its components pack it, and deliver it to someone very easily.

Compact Design

After complete installation, FDM technology-based printers are quite simple and thus do not take up too much space. Although the external volume of the printer is totally dependent on the printing volume you want. Then also apart from part printing volume, its other parts like the outer frame, power unit, etc. don’t take much space.

I myself have placed it over my refrigerator sometimes.

Printers based on FDM printing technology can easily be categorized as desktop 3D printers.

Cloud Server Printing

This is the most advantageous feature of FDM printers although others are adopting this rapidly. In these printers, you can give printing commands with the help of a cloud server.

This means that if your 3D Printer is connected to a power supply and a network, then you can give it a printing command from anywhere with the help of the cloud printing option.

This feature is feasible in FDM printers because these printers require very less attention while printing. You can literally start the print and forget about it.

Trending Posts

- DIY 80mm EDF And Thrust Test – All Steps

- DMLS 3D Printing Advantages & Disadvantages | Detailed

- 3D Printer Nozzle Issues | Solution & Details

- The Best & Cheapest IDEX 3D Printer | 2022

- 3D Printer Nozzle – Changing And Assembling Them

- Flexible Filaments Print Ideas | Settings & Ideas

FDM Printing Disadvantages In Detail

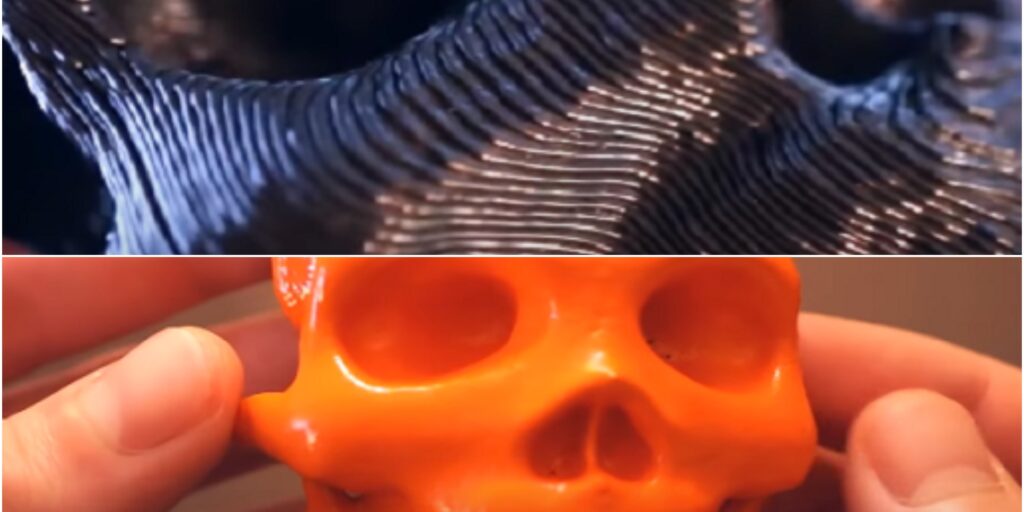

Rough Surface Finishing

Due to height and adhesion technology, the finished product made by FDM 3D printers is not very good. These products have rough surfaces. One method of eliminating these rough surfaces is by post-curing processes.

Some of the most common post-curing processes are-

- Acetone application.

- Gap filling

- Priming & painting

- Epoxy adhesion

Warping is common

While printing large flat surfaces in an FDM 3D printer the warping error is the most common. In this, the layers tend to bend in any direction i.e. upward or downward.

This causes the adhesion of the next layer very difficult and sometimes it also results in the failure of the whole 3D print.

This can be cured by printing in small parts or by optimum calibration of the FDM printer before giving the print.

Nozzle Clogging

The main principle of FDM 3D printers is to melt the filament and pour them layer-by-layer on one another to form a 3D structure. Now while doing this process sometimes filament get stuck in the nozzle and this causes clogging of the nozzle.

This also happens due to the irregular temperature settings and also when printing is very fast with respect to the pace of melting of filament.

So one thing we can do to prevent this is the proper calibration of the printer before printing, thus our melting and pouring speeds are in sync with each other and preventing clogging of the nozzle.

Longer Printing Time

As FDM printers print layer by layer the total printing time sometimes reaches in days for a normal model of average volume.

The printing time also depends on the selected quality, layer height, etc. of the 3D print you want.

Layer Adhesion Problem (Layer Shift)

As we have told earlier that FDM printers basically worked upon layer by layer and while working with these layers it is common that sometimes the adhesion between layers gets weekend.

Weakening of adhesion between layers results in the opening of layers which causes the failure of the print or misalignment of the upper layers which also results in the print failure.

Weak in Strength

Commonly the FDM prints are done layer by layer one above another in a single direction. This unidirectional printing makes the printing fast but also it makes the prints prone to breaking.

If you take a 3D print made by FDM technology and apply a very normal force then it will break very easily.

One way to strengthen the print is to print multidirectional i.e. one layer on the x-axis and the other on the y-axis.

Bed Calibration Needed Frequently

After two to three prints the bed calibration of FDM printers gets misaligned. This is mainly due to the back and forth motion of the bed during printing.

If you don’t correct the alignment of the bed after every print then your next print’s initial layers will get distorted and may result in print failure.

Conclusion

Overall FDM technology-based printers have more advantages than disadvantages. Most of its disadvantages are due to the poor calibration of the machine which can be attributed to a user-generated fault. So if you keep everything in check, FDM printers are one of the best 3D printing technology to start with.

Once you get comfortable with FDM printers you could move towards more complex 3D printing technologies in the market.

Very Precise and to the point. Thanks for this, I was searching this for a long time.