SLA or Stereolithography is laser-based 3D printing technology. This laser-based technology is quite new in the 3D printing industry so it’s still evolving. If you are thinking to purchase an SLA technology-based 3D printer then this post is for you.

We own few SLA 3D printers and one of them is Peopoly Moai, so we think that we could tell you about their advantages and disadvantages in detail.

Please keep in mind that this post is written keeping all SLA technology-based printers in mind and is not directed at any specific company or printer model.

What Is The Main Advantage & Disadvantage of SLA 3D Printing?

SLA 3D printing’s main advantages and disadvantages are its finishing and cost respectively. It can print detailed miniatures of almost perfect quality. Its resin and printer itself are still heavy on pocket.

Now, there are many other advantages and disadvantages related to SLA printing so keep on reading. We have discussed some important from them in the blog further.

Also Read: FDM Printing Advantages & Disadvantages

Advantages & Disadvantages of SLA – Table

| S.No. | Advantages | Disadvantages |

|---|---|---|

| 1. | Smooth Surface Finish | High-Cost |

| 2. | Print Complex Pattern | Easy to handle but still some parts requires attention. |

| 3. | Best for Miniatures | Not environment friendly. |

| 4. | Short Print Time | Required Perfect Assembly of the printer. |

| 5. | Easy Ergonomics | Need curing after print. |

| 6 | Variety of Material Choice | Somewhat weak in Strength. |

| 7. | Easily Portable | Could not print large prints. |

| 8. | Compact Design | The laser and Transparent display are fragile. |

SLA Printing Advantages In Detail

Smooth Surface Finish

SLA printer uses UV laser or transparent LCD with a UV lamp under it to form a layer image on resin tank. In this process, the resolution of LCD or Laser is very high thus the final part surface is very smooth.

This is almost the same as FDM Printer but with a very thin layer height. This results in very smooth finished prints.

Print Complex Pattern

Many design prototypes need some predefined internal geometry for their working operation. For an FDM printer, it is a complex task to print internal geometry with accuracy but in an SLA printer, you can print complex patterns with accuracy internal and external.

After adding some geometrical patterns in part design, the overall strength of the part also increases. In engineering prototypes, parts need internal cooling or an internal cavity for fluid flow this can be achieved by SLA with accuracy.

Short Print Time

This printer’s printing time totally depends upon the printing volume, not on the complexity of the print.

SLA printer did not need to wait long for solidifying of resin, resin becomes solid instantly when UV light is struck with it. Also, it has fewer mechanical parts thus it is able to move faster with accuracy and high resolution.

Some hybrid resins are a mix of secondary components like(Fibre, Ash, etc) so they need a little more time due to their less transparency of resin.

Easy Ergonomics

Ergonomics means the connection between humans and machines. Believe me, SLA printers have the most efficient connection between both. You will not face any difficulty while operating this machine.

Only after a print, you need some wash to remove the excessive resin. It always feels like SLA printers are pointing you to the next step themselves. All the options and steps in printing are super easy.

Variety of Material Choice

Material i.e. Resin used for SLA 3D printing is available in various options. There are more than 50+ resin options available to be used in SLA printing.

Technically there are two main types of resins

- Standard Resin

- Advanced Resin

Standard Resin:- Its is a commonly used resin in SLA printers. It has a good surface finish, normal Structural and Thermal properties, and normal mechanical properties.

Advanced Resin:- Resin has the best Structural, Thermal, and Mechanical properties according to its application of use are advanced Resin. These resins mostly use in Engineering, Medial, and Industrial fields due to their properties.

Some Resin is also a mix of two or more components and makes hybrid material that has multiple material properties.

Bio-Based Polymer Resin:- These types of resin are environment-friendly and biodegradable not 100% but better than standard resin.

Water Washable Resin:- These resin prints did not require isopropyl wash to clean excessive resin from print. They can be wash with water only.

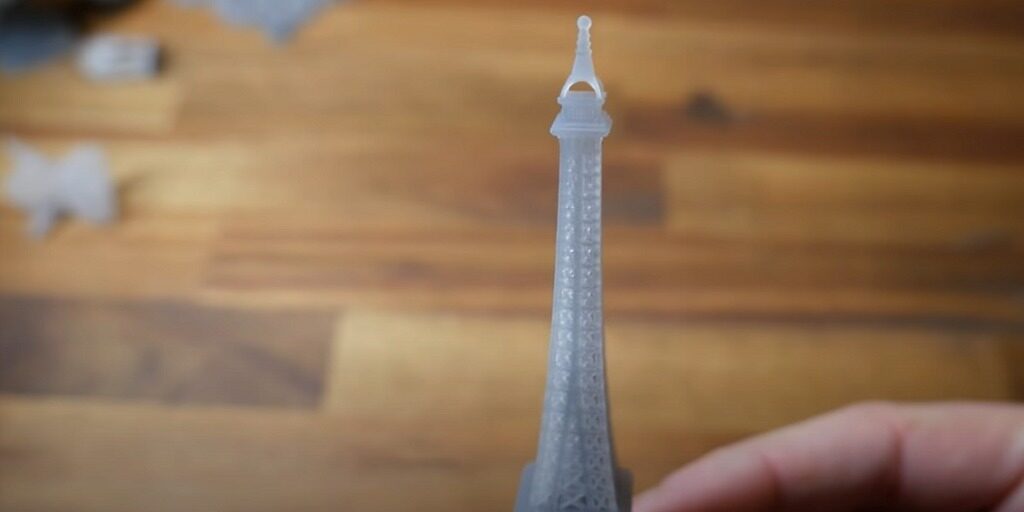

Best For Miniature 3D Printing

SLA 3D printers use laser for forming models, lasers being very precise and small gives perfect result with very smooth finishing. Due to these properties, SLA printers are best for 3D printing miniatures

SLA printers are generally famous for making 3D models and prototypes of jewelry, circuit boards, and other small parts that have very small printing volumes.

Below is one of the 3D prints that we have done through the Peopoly Moai SLA 3D printer. Just look at the finishing of the tip even we were amazed by the results.

Trending Posts

- Exploring Thrust Variations with Variable Nozzles in 3D Printed EDF Engines

- DIY Parachute for Drone | 3D Printed Safety System That Saves the Sky

- DIY 80mm EDF And Thrust Test – All Steps

- DMLS 3D Printing Advantages & Disadvantages | Detailed

- 3D Printer Nozzle Issues | Solution & Details

- The Best & Cheapest IDEX 3D Printer | 2022

FDM Printing Disadvantages In Detail

HIGH-COST

Due to the use of high-power lasers and the cost of printers is higher in the early days, after the use of LCD and innovation in technology, SLA printers also become cheaper.

You can purchase a good-quality desktop SLA printer for under $200. SLA printer cost also depends on their resolution provided by LCD, Some companies provide 4K resolution LCD with the printer to achieve higher details on print.

Need Support In Print

In SLA printers most desktop printers use the bottom to up process to print in less space due to this printed part always hangs in the air with the print build platform. So we need to attach some support to the part to increase the surface area of contact with the build platform to stop it from falling.

Although giving supports gives strength to the printing process, this also increases our work and material use. We need to remove supports after printing is finished in the post-printing curing process.

Giving supports also increase the usage of printing resin which is not reusable in any way. In FDM printing you can use other materials for supports but then you will need a dual extruder 3D printer, which can change between the support material and primary material.

Need Curing and Washing After Print

When SLA finishes Printing the part you need to clean the part to remove excessive resin due to the stickiness of the resin creates a mess around.

You need isopropyl alcohol to clean the excessive resin from print but some manufacturers also offer water cleanable resin so you can clean resin with water only.

Some resin print required post-processing after print. In ceramic resin, you need to cure it in a furnace with a controlled temperature to create complete ceramic parts. This results in your part shrink after vaporization resin but you got the full ceramic part with high thermal properties.

You also need to clean the printer before you switch to another different type of resin.

Not Enviorment Friendly

Most resins are not environment friendly also not safe for your health due to their odor. But now companies also offer environmentally friendly resin and also biodegradable.

Fragile Parts

Typically almost all SLA printing technology resin have the strength of 10-40 Mpa, which is quite fragile. SLA printer core parts are laser, LCD, and UV lamp. These parts are fragile so you need to careful when handling or moving the printer from one location to another. Also with time you need to change the parts when their intensity became low.

Weak in Strength

Standard Resin printed parts are week but using advanced resins or hybrid resin you achieve better strength. But advanced resins are costly.

With an SLA printer, you can print high structural, thermal, and mechanical properties part but the only cons are that you need to do post-processing after print it also increases the cost of the print.

Build platform Calibration Needed Frequently

After successful print you need to remove your part from the build platform in this process you decalibrate the build platform which happens with each print so you need to calibrate the build platform after each print.

Conclusion

If we consider all the advantages and disadvantages of the SLA 3D printer then we can say that this is a 50-50 battle. Some of the advantages make it far superior to other printing technologies like its ability to print 3D miniatures, smooth finish, etc. But some of its disadvantages like printer price, resin price, flexibility in printing, etc. put it far behind, even in comparison to normal FDM printers.

Overall we can say that if you are familiar with the 3D printing process and have spent quite a bit with other 3D printing technology printers then you can go with this one.SLA 3D printers are perfect for persons in the small modeling and prototyping industries.

Hope you have liked our post and if you are confused then comment on your requirements we will suggest a 3D printer for you. Thank you