With SLS (Selective Laser Sintering) 3D printers getting cheaper daily, everyone is thinking about buying one of them. But are they really that affordable or are there some hidden costs that you should know about? Let’s discuss all these things in this post on SLS 3D printing and exactly how Budget-friendly it is?

When this technology was new the SLS 3D printers were mainly made for industrial-level 3D printing. Their cost was easily above $ 30,000 but now with the advancement in technology many more desktop SLS 3D printers are available in the market with their price being in the 10,000 range. This price drop opens us a path towards SLS 3D printing but there are indeed many other costs involved with their 3D printer like maintenance, raw material, labor, etc. We will discuss all these points one by one.

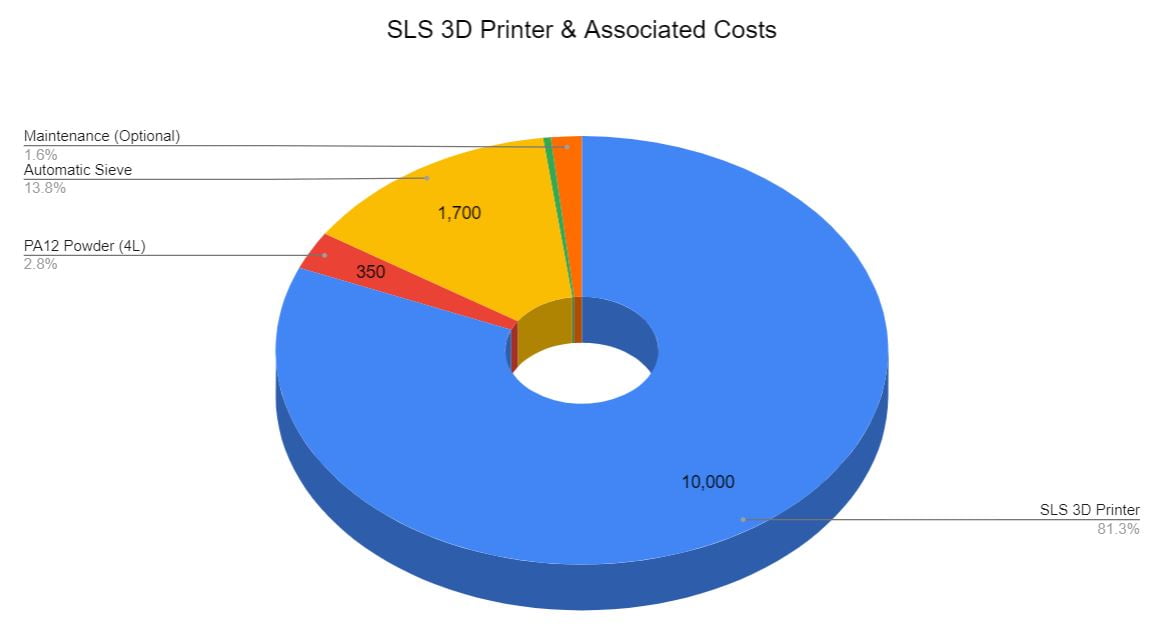

What is the Rough cost of owning an SLS 3D printer? Just owning an SLS 3D printer will cost around $11,000 this is only including the cost of the printer and its raw material the other costs may vary as per the use. This price is for the cheapest SLS 3D printer in the market with normal quality PA-12 Powder as raw material.

SLS 3D printers are material friendly as they don’t require supports and hence don’t waste any material. A PA-12 powder bottle costs around 350 dollars this will be used for making many models and thus can be considered not much expensive.

Other costs that are associated with the SLS 3D printing are our maintenance and labor costs. Maintenance is always required whether it’s an SLS printer or an FDM 3D printer. The only difference is that the FDM printers are very cheap when it comes to maintenance and you can do most of it by yourself. While SLS 3D printers require some expertise while handling them.

Initial Cost of SLS 3D Printer

Acquiring an SLS 3D printer mainly includes two things first one is the SLS 3D printer and the other is the Raw Material commonly known as a powder in SLS 3D printing.

Desktop SLS 3D Printer

Just 2 years ago buying an SLS 3D printer for a hobby printing was out of the question. Then the cheapest SLS printer was easily over 30,000 dollars, but now with expanding technology and increase in the competition has brought down the prices significantly.

Now the cheapest SLS 3D printer can be brought in 10,000 dollars or so. They have also become much smaller in size and can be easily categorized as desktop 3D printers.

Currently, Formlabs Fuse 1 is the best SLS printer which is not too expensive although it lies in starting of 10,000 dollars range, it’s justifiable according to its quality and reliability.

Formlab Fuse 1 Details-

- Price – $ 9,999

- Build Volume – 165 x 165 x 320 (mm)

- Company Origin – USA

You can check more details and prices here.

The other option is to use an SLS 3D printer DIY kit. The do-it-yourself kit is much cheaper and it also helps you understand the working of the printer.

Currently, there is only one DIY kit that is reliable enough to be recommended i.e. Sintratec DIY SLS Kit. The downside of the kit is that it has a lesser build volume than Formlab Fuse 1, but its price difference can easily cover up that.

Sintratec DIY SLS Printer Kit Details-

- Price – $ 4,999

- Build Volume – 110 x 110 x 110 (mm)

- Country of Origin – Switzerland

Using a DIY kit will save you a lot of money but it’s advisable to go through this method only if you know SLS 3D printing and its working. If you are keen on learning in the process and have some money to experiment with, you can also go with this method.

Raw Material for SLS 3D Printer

SLS 3D printing uses Nylon as a raw material it is available in two forms Nylon 12 and Nylon 11. Nylon is a thermoplastic material that fixes its position when heated. Thus, it is best for industrial use because it also has high ductility and is perfect for end-user production.

Between Nylon 12 and Nylon 11, Nylon 12 is the most commonly used raw material. As it is more versatile has high detailing properties and it is cheaper than Nylon 11. On the other hand Nylon 11 has high strength and is best for industrial use where ductility, durability, and elongation are required as physical properties of the material.

A normal PA-12 powder (Nylon-12) costs around $ 350 for 4 litres. You can do 8,00,000 mm3 printing with it, but it is an approximate number as some powder will be wasted. Here you should note that there is no need for support structures in SLS 3D printing. Thus the volume of powder is equal to the print volume of the model to be printed.

So it’s safe to say that SLS printer raw material is costlier than FDM raw material but cheaper than the SLA 3D printer’s raw material for the same volume of the model printing.

Thus, the initial cost of purchasing an SLS 3D printer can be approximately $10,350. (Estimate may vary a little bit due to fluctuation in prices)

Maintenance Cost

SLS 3D printing requires more handling and maintenance between the prints. The most tedious part of SLS printing is its powder as it is very fine and could easily blow during the transition process. During printing, the SLS printers require very fine sieved powder if there are any lumps it will result in print failure.

After every print, you have to remove every bit of powder from the feed bed and the print bed. Then you have to put it in a sieve and add some refreshing powder as required (Refreshing powder is not required if you are using Flexa powder).

After sieving, it is required to be kept in an airtight container and stored in a properly ventilated cool place. All this seems to be a very short process but if you are doing it for every new print then it will become tiring. In the case of FDM printers, we have to do nothing for every new print you just give this instruction, and the print is started. In the case of SLA 3D printing, the resin is needed to be changed but that is not also a big task.

So from our experience, we can say that SLS 3D printing required more maintenance than other printing technologies. Although you can do all this by yourself if you are in hobby printing. But, if you are running a business then you will need someone to do all this which will require some amount to be paid. In the long run, this could become a large sum of money that you need to pay for the maintenance of the SLS printer.

Labour Cost

Labor cost is one of the most overlooked costs in the 3D printing industry. It is most significant when you are printing a large batch of models. But in the case of hobby printing, it is not that significant as you will do most of the work yourself and the labor cost will be very low to negligible. Labor could include anything like quality-check for the finished model, giving printing instructions, etc.

For comparison, we can say that SLS 3D printing requires a good amount of labor, as the models are printed in between the powder and you have to each time remove excess powder from the model and clear them. Then the powder is needed to be cleared from the feed bed and print bed and then sieved for the next print. This sometimes becomes a hefty task. But, still, these finished products do not require any more post-printing curing or sanding which is required in FDM printed parts.

On the other side in FDM and SLS 3D printing model removal is very easy and requires very little labor. The exact labor cost of each type of printing technology is not fixed and cannot be calculated as it varies from person to person and on their expertise, it can go from 5 dollars apiece to 50 dollars apiece.

FAQ Related to SLS 3D Printing Cost

What is the fixed cost of purchasing an SLS 3D printer?

Most of the cost is of SLS 3D printer which starts with $ 10,000, after that its raw material costs around $ 350 for 4 Litres. Apart from these things you may also need a sieving machine which also costs another $ 1,700. There are other miscellaneous costs also while printing.

Conclusion

If you calculate the lump sum amount that you need to run an SLS 3D printer then it will easily reach $11,000 for the first print. But after that, the cost is of raw material, maintenance, and labor which is miscellaneous, but we can add $ 500 per month for that in case of a small business with a low number of model printing.

In our view, if you need quality and strength then you should go with SLS 3D printing. Otherwise, you should try SLA printing which is also a great option in quality standards. But, if you are at entry level in 3D printing then you should start with FDM printing as it will give you proper knowledge and experience in working in a 3D printing environment.