Each & every machine requires maintenance after a given period of time. 3d printer nozzle cleaning is one of the similar tasks in the 3D printing niche to keep the workflow smooth. It is important to do these unclogging, cleaning, and refurbishing processes from time to time otherwise they may lead to some major part failure.

But first, let’s address a straight question in your mind i.e. How to clean Filament off nozzles? One of the best and simplest methods is to use a needle, you just need to heat the nozzle to the melting point and then force the needle from the nozzle’s opening. This will remove the clogged filament up to a certain level. There are other ways to remove the more harsh clogging, they are given in the article further.

3d printer Nozzle clogging is not much common, they last long unclogged for years but if you do not carefully use your printer it may cause nozzle clogging. Let’s look deeper into the process to understand it more clearly.

In The Post:-

- Types of Nozzle Clogging

- Nozzle Unclogging & Cleaning Solutions

- Causes Of Nozzle Clogging

- Nozzle Clogging & Associated Problems

- FAQ

- Conclusion

Types of Nozzle Clogging

Before going for solutions let’s segregate the nozzle clogging a little bit. 3d printer nozzle clogging is of mainly two types. The first one is a partially clogged nozzle and the second one is a completely clogged nozzle.

Partially Clogged Nozzle

In Partially clogged nozzle derbies of the clogging material is stick to the wall of the hot-end or they come continuously from other sources which cause the problem. In this, the flow of the molten plastic is slow down and the problem of extrusion occurs frequently. This happens due to dust accumulation in the hot-end or using contaminated filament or working dusty environment.

Completely Clogged Nozzle

The completely clogged nozzle is not able to extrude the molten filament because the clogged material forms a large size which is now large than the nozzle tip diameter so the molten plastic is not able to push it out of the nozzle.

3d Printer Nozzle Unclogging & Cleaning Solutions

When we search for 3d printer nozzle cleaning nozzle blockage on the internet we found multiple methods which are used for removing the blockage from the nozzle so here we tell you about some of them which are mostly use and effective.

- Using Acupuncture Neddle

- Deep and shaking bath of the dissolve chemical

- Cold Pull

- Using Brass Brush

- Hot Air gun Or Blow Torch

Using Acupuncture Needle

The easiest and fastest method for removing a clog from the nozzle is to use an acupuncture needle to break the clog into small pieces thus it comes out through the flow of the melted plastic. The acupuncture needle is flexible and strong enough to break the clog inside the nozzle when you have done it in the correct way. For this method follow the below methods to remove a clog from the nozzle.

- First heat up the nozzle to the filament melting point.

- Now take accupuncture needle which has smaller diameter than the nozzle tip internal diameter.

- When the hotend reach at the set temperature take needle and push it into the the nozzle through tip.

- After inserting the needle in nozzle push it up and down and rotate it to remove and break the clog.

- When clog break and you did not feel more clogging inside the nozzle, send comand to printer to extrude the some amount of the filament.

- When hotend extrude you can see the clogged material broken by the needle coming out of the nozzle.

From the above steps, you can unclog the nozzle using an acupuncture needle but if you do not have an acupuncture needle then you can also use a guitar string or any thin Single strand wire (Which has only one metal wire) with the lesser diameter of the nozzle tip.

Dissolving In Chemical Solution

In this method, you need to disassemble the nozzle from the hot-end. When you unscrew the nozzle from the heat block then use chemicals to dissolve the plastic of the nozzle.

The choice of choosing chemical depends on the filament material type which was stuck inside the nozzle. Mostly Acetone is used as a dissolvable chemical because it can solvent a wide variety of polymers but it is better to check the chemical for material solvent.

To use this method follow these steps below:-

- First heat up the hotend to 200oC then turn off the printer (this step is to remove the nozzle quickly without much effort).

- Now use two wrench, grab the heatblock from one of the wrench and use another wrench to rotate the nozzle in counter closk wise direction to unscrew the nozzle.

- When nozzle come out then lefave it to cool down.

- Put actone in glass jar of cup now drop the nozzle in it.

- Acetone starts the dissolving process of the polymers but for more fast reaction you can also shake the jar.

- After 10 minutes take out nozzle and observe it, if any clog is left then reapet the process untill every small plastic is clean.

- Screw the nozzle back in heatblock when cleaninig is done.

NOTE:- You can use this method for mostly polymers filament. But when you use acetone to make sure you are in an open environment because acetone release fumes also catch fire easily which causes injury or accident.

Cold Pull

In the Cold pull method for 3d printer nozzle cleaning, we use the slipperiest and less brittle filament. It is also known as the Atomic Pull method. This method does not require to disassemble of the nozzle.

Mostly nylon is used as the nozzle cleaning material for the cold pull but if you do not have nylon or any nozzle cleaning filament then use the slipperiest and less brittle filament from your inventory.

To Perform the cold pull follow the given steps:-

- First remove the old filament and bowden tube from the hotend.

- Now after removing old filament and bowden tube heat up the nozzle to printing temprature of the nylon or of your cold pull filament.

- After reaching the printing temprature feed the cold pull filament through hand and push it until the old material come out from the nozzle. When you see clear cold pull filament coming out from the nozzle then cool the hotend to 60oC – 50oC while keep the pusing force on the filament.

- When hotend reach at 50oC then release the pressure from the filament.

- Now set the hotend temprature to 100oC – 120oC.

- Reaching on the set temprature use force for pulling out the filament from the hotend.

- When the filament came out you can see the clog particle stuck with the filament and filament has negative image of the nozzle internal.

- Cut the dirty filament and repeat the process untill you get clean filament fron the hotend.

Using Brass Brush

Sometimes nozzle is too low to the build platform or accidentally crashes in the print which causes the molten plastic to stick to the nozzle all over and around it. This also causes the nozzle to clog from the outside.

But removing this clog is very easy you just need a brass brush to clean the nozzle. To do this follow the below steps:-

- First Heat up the nozzle to material printing temprature.

- Now use Brass brush and rub it on the nozzle.

- You can also use shrap blade to remove the stucked plastic from the nozzle.

Note:- In this method do not use steel brushes with brass nozzle because brass is less hard material in comparison with steel. Thus using a steel brush causes a scratch on the nozzle or damages the nozzle’s outer surface.

Hot Air Gun Or Blow Torch

Be careful while using this method and follow every safety precaution.

In this method, you need to use a hot air gun or blow torch to clean the clog from the nozzle. This method requires the disassembly of the nozzle. After disassembling the nozzle follow the given steps to perform this method:-

- Now put the nozzle on the ceramic sufrace or in the groung or any surface which can withstand extreme heat.

- Use hot air gun or blow torch for heating up the nozzle first use the hot air gun or blow torch at half of their power.

- After heating the nozzle use plliers to grab the nozzle and use twezzers or needle to clean the nozzle.

- If nozzle is not clean then increase the temprature of the hot air gun or blow torch.

- Repeat this process untill you clean the nozzle.

In this method, sometimes people heat up the nozzle until all the plastic is burned. But sometimes excess heat damages the nozzle.

NOTE:- Do not use this method with ruby tip nozzle or with assembled nozzle because in extreme heat ruby crystal got damage or in the case of assembled nozzle they bent or got deformation in their structural dimensions due to use of different material in their construction because different material expands on a different rate.

Causes Of The Nozzle Clogging

- Bad assembly of the Hotend.

- Contanimated Filament.

- Dust acumulate on filament.

- Unclean Hotend After Filament Change.

- Moisture absorve By Filament.

- Nozzle Life Period is Over.

Bad Assembly of the Hotend

Hotend has multiple parts which screw and tighten to each other. If you assemble your hot-end by yourself so there is a chance that you do not screw the nozzle completely in the heat block or you do not screw the heartbreak completely in the heat block.

Thus, this causes the gap between the heartbreak and hot-end in heat block which is not seen by eyes. while printer operation this gap filled with melted plastic.

This plastic keeps sticks there because it does not get the push from the new arriving filament. After long use, this struck plastic degrade into some sticky plastic which increases with the use of the printer and then it clogged the nozzle completely or partially.

Contaminated Filament

As we know most sellers sell filament on a weight basis. Some non-authorized manufacturers use contaminated material to make filament heavier and increase their profit. Thus this contamination is come in our nozzle with filament and does not melt. With the regular use of the contaminated filament, this contamination keeps growing into the nozzle which lastly blocks the nozzle or damages it internally.

Dust Accumulate on the Filament

When we use filament with dust accumulate on it without cleaning out the dust because we think that it has very small particles so it cant block the nozzle but in reality, these small particles also cause the blockage in the nozzle.

Dust particles are not melted in the hot-end and keep going in flow with melted plastic but when any large particle or any small particle of dust is stuck in the nozzle so from there this particle starts growing by adding more and more small particles and grew enough large to bock the nozzle.

Unclean Hotend After Filament Change

Sometimes we forget to clean the nozzle before the filament material changing. We remove the old filament then it left some very little amount in the hot-end which mix with new different material and form the mix of the two materials which shell have higher melting point than we use so this also causes the nozzle blockage.

But there is one thing that if we use a new material that has a higher melting point than the previous filament material so the leftover old filament starts cooking in the excess heat which makes it stick or brutal which can also able to block the nozzle.

Moist Filament

3d printer Filament mostly which is used by new ones are very sensitive to moisture. when you unpack them their melting point are approx same as describe in the product manual but after some time lying open they did not melt perfectly on the refer melting temperature by manual this is happening because filament absorbs the moisture from the environment thus its melting point is now higher than the reference by the manual.

This moist filament also causes the problem of nozzle blockage. When we use moist filament without dry out in a heater or oven then this filament loses water vapor inside the nozzle where the filament melt. This water and Melt Plastic create a mix of sticky plastic which hard to extrude from the nozzle which causes a block in the nozzle.

Nozzle Lifespan Is Reduced

Sometimes we use 3d printed regularly for years without checking it part working time given by the manufactures. When your 3d printer nozzle life span is over then this also causing the problem of nozzle clog.

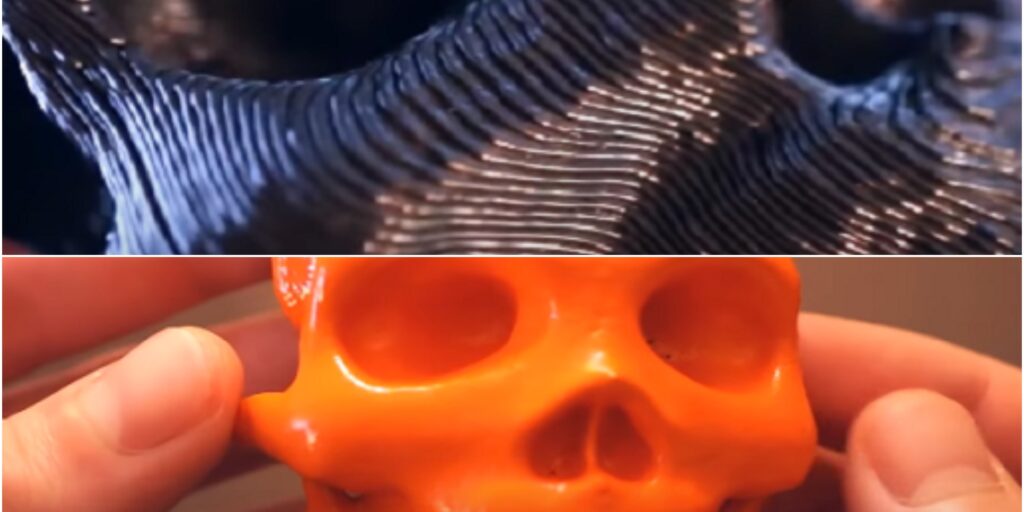

Nozzle Clogging & Associated Problems

When the nozzle is clogged so it shows the same identical symptoms as we see when our extruder is not working correctly so it is better to check the extruder before going for the nozzle. Here are problems that start occurring if we do not perform 3d printer nozzle cleaning.

Nozzle blockage shows these symptoms:- extrusion

- Under Extrusion

- Missing Section in Print

- Nozzle Pick Up Printed Material

Under Extrusion

When the nozzle is clogged your print suffers from an under extrusion problem in which the hot end is not able to extrude the consistent amount of the melted filament so you can see gaps and voids in your print.

Missing Section in Print

Sometimes when the nozzle has blockage it stops extruding the filament but when the pressure reached certain levels due to the pushing force of the extruder then the clog pushes out from the nozzle and thus nozzle is now able to extrude the molten plastic. This Event causes the missing section in the print. This missing section will be anywhere in the print it should be a complete layer or it should be infill in the print.

Nozzle Pick Up Printed Material

This problem mostly occurs in Partially clogged Nozzle. When the Nozzle gets clogged Partial so the flow of the molten plastic is not straight but it comes out at an angle from the nozzle. Sometimes this angel is too large and the molten plastic is starting sticking to the nozzle and block the nozzle.

Incorrect bed leveling and wrong z-offset height also cause this problem.

FAQ

What are some common methods of unclogging a nozzle?

Some of the easiest methods for unclogging a 3d printer nozzle are using an acupuncture needle, chemical solutions, and cold unclogging methods.

What are the problems caused by the clogging of a 3d printer nozzle?

If the nozzle of a 3D printer is clogged then it may result in Under-Extrusion, missing sections in print, and tangling of printed material.

Conclusion: Nozzle Unclogging/Cleaning

From above we know about various types of events that cause the problem of the nozzle blockage and we also discussed the methods of unclogging the nozzle. Amongst all the cleaning methods provided in the article, it depends on your nozzle type and your work type which method you want to use.

3d printer nozzle cleaning is one of the easiest tasks to do and if you do it in the correct manner with all precautions. Some important precautions for the long life of your nozzle are below:-

- Always Clean the nozzle before using different material filament or changing to new chosse filament.

- Correctly Level your Build plate and set correct z-offset.

- Use Piece of foam around filament before entering in to the extruder. This foam clean the dust from the surface of the filament so dust particle are not arrive in hotend.

- Keep clean your nozzle from outside using brass wire brush.

- Choose nozzle type according your filament material type.

- Beware of using contanimated filament.