Looking to start SLA printing? Having trouble recognizing the perfect resin printer? Or finding difficulty in handling supports? Don’t Worry !! In the article below, there are some of the tips and tricks discussed on the know-hows of SLA printing.

SLA printing is one of the major forms of additive manufacturing techniques. But, it has some unique strengths, that make this technology stand out. However, the SLA printing is a little more convoluted, mainly for those who have no 3D printing experience. It is harder to react as the problem does not have immediate reactions.

What are health-related problems associated with SLA 3D Printing? The most common health-related problems associated with SLA Printing are chemical allergies, skin exposure, ingestion of fumes, and eye exposure. These problems are all related to the chemical resin used in the SLA printing technology. We have discussed them, and also discussed other important best practices in SLA printing to be followed for best results.

In The Post:-

- SLA Printing Best Practices In Short

- Precautions For Chemicals In SLA Printing

- Best Practices To Be Followed

- FAQ

- Conclusion

SLA Printing Best Practices In Short

SLA printing is best suited for some minute detailings and miniature prints. The layers that are but 50 microns thick are supported in the pace to the rougher layers in FDM, which measure within the many microns. Safety is the foremost aid that one needs to take into consideration. Therefore, being cautious can prevent many tragedies or disasters of the same. Here, you can take a look at some of the safe operations for SLA printers are :

- Printers should be kept in well-ventilated areas of limited occupancy.

- Make sure to wear protective clothing to avoid any skin damages.

- Consult Safety DataSheet (SDS) – This datasheet provides a detailed information regarding the pros and cons of some hazardous chemicals. And prevent you from toxicity , flash pointn or exposure controls etc.

- Wash your hands frequently.

- Avoid any eatables around the corner. Or handle cosmetics and get in touch with lenses in your designated 3D printing area.

- Store your airtight containers in a cool place.

- While working with prints, avoid using items or tools other than the resin printing materials.

- Avoid splashing resin.

- Change your gloves frequently.

Although SLA printers sound dangerous, they are quite safe when they are handled cautiously. Let us dig deeper into the essentials of SLA printing. Below are five common health problems linked with SLA printing, so understand them correctly and follow proper precautions.

Precautions For Chemicals In SLA Printing

Chemicals are dangerous and cause irritation. You need immediate medical assistance if the exposure is too much. Therefore, always wear latex gloves, protection glasses, or a respiration mask.

While working with prints, the resin releases some kind of fumes, that causes infuriation. You should avoid letting any of the fumes into the respiratory system. The best one can do is place our resin printer in a good ventilated room.

Cover your work surface with paper towels or plastic sheets to avoid creating any mess. As resin is highly reactive and it may leave some permanent stains on your desk or floor.

The best one can use are plastic sheets, as they can be reused after washing. Clean the equipment and workstation regularly.

Skin Exposure

- Wash the skin with soap and water.

- Remove any contaminated clothing and clean it before use.

- Avoid exposure to UV light.

- Wear long sleeved pants and shirt to avoid any exposure of your skin.

- Put on protective footwear with closed toes.

- Take any medical assistance for instant reliefs.

Eye Precautions

- In case of infuriation, hold eyes open and continuously wash with a gentle stream of clean water for atleast 15 minutes.

- If the irritation is due to the vapors, reduce the exposure.

- Avoid exposure to UV light.

- In unavoidable situations, take medical assistance immediately.

Ingestion

- Do not induce vomiting. Drink water or milk.

- Avoid mouth to mouth breath to an unconscious person.

- Seek medical attention immediately.

Inhalation

- Seek for fresh air , in case of excessive vapors.

- Seek medical attention if further irritation develops.

- Make sure the printing is done in ventilated areas to prevent any kind of disasters.

Sla Printing Best Practices To Be Followed

Air Bubbles

Always shake the resin bottle before use. But, shaking the bottle upside down may create some air bubbles in the bottle. A better approach is to either whirl the bottle between hands or swirl the bottle around. It may avoid excessive bubbles inside the bottle and prevent creating any accidents.

Leveling Build Plate

The distance between the glass and build plate should be as thick as the size of a sheet of paper. Tighten the screws to hold the build plate in place.

The build plates have different textures on the bottom of their prints such as materials like glass, PEI, or Kapton tape have a smooth surface; while the glue on the polycarbonate sheet has a matte finish.

Evade the usage of spray to remove prints. You can try experimenting on different surfaces and adhesives to see which method not only works best with your setup but also leaves a finish that complements the print. A three-point leveling technique is considered the best.

Carefully Slice Your Model

Slicer converts a 3D model into the instructions that drive a printer, and it is one of the most important SLA printing best practices.

It controls the printer’s temperatures and movement, whether additions like supports or rafts are printed, and countless more factors about the printing.

The packaging of good resin printers comes in its own slicer software. This allows the printer to divide the model into very thin “slices” which determine exactly where the concentrated light will hit the resin vat. Make sure that you have a quick fix for your neat prints i.e., it should have “fine” or “hyper” quality settings. The results are worth being patient enough of.

Printing Flat Surfaces

For an inclination of about 10-20 degrees, the success rate of large, flat surfaces increases but this isn’t fixed. The surface area of each layer decreases, with the amount of contact the print has with the tank. It actually tells us that the print is subject to less force as the build platform raises every year.

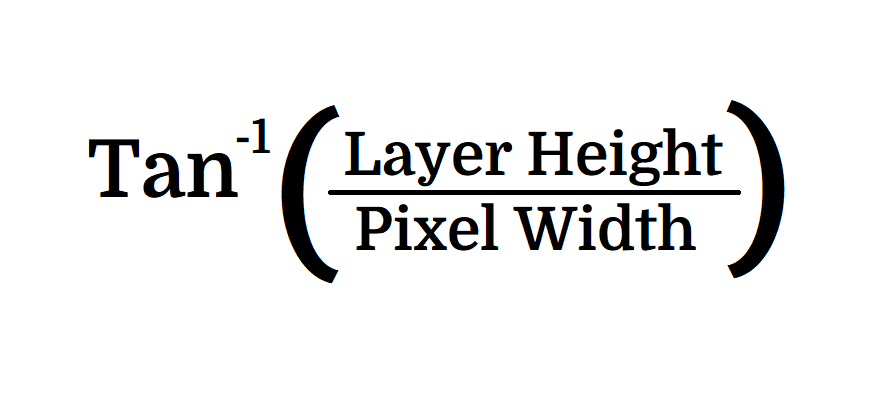

For best Flat surfaces see our blog on SLA Printing Flat Surfaces, overall we can suggest using the following formula for determining the inclination of the flat surface from the bed axis. Check it before printing the actual model by using our XYZ calibration Cube (FREE) or other 3D printable STL files.

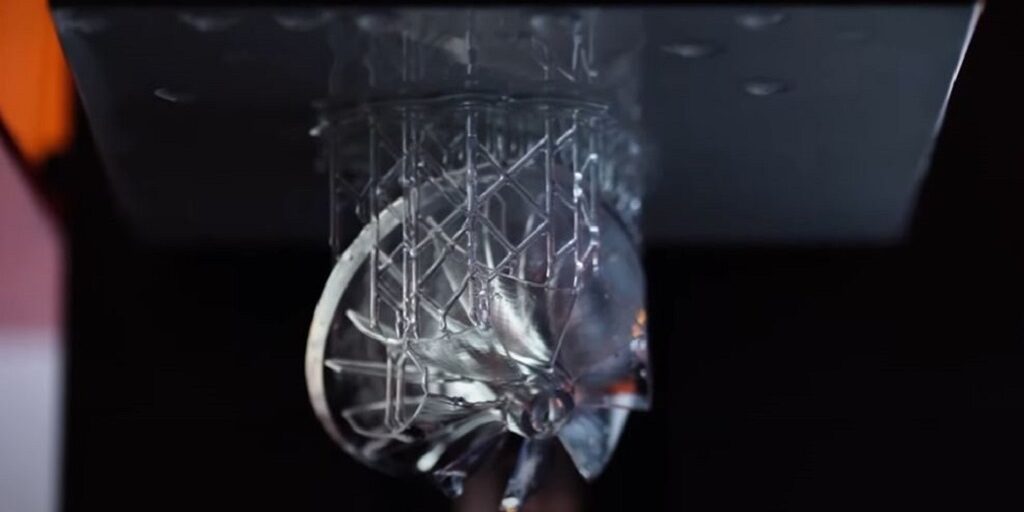

Support Removal

It is quite burdensome to print designs with support. But, they are the prime requirement in designing 3D prints.

You can remove the support structures by fully curing the resin. That means the support structures will get softer and should be snipped off easily. Pliers or small knives are the best tools for this job.

Moist your 3D prints for a better way or wash them directly to the curing station before you attempt to remove any support structures. The supports are going to be stiffer, but their removal is going to be less likely to disturb the print’s desired geometry. That said, you must be very gentle on this step, particularly if the print contains weak and spindly segments.

Filling The Build Plate

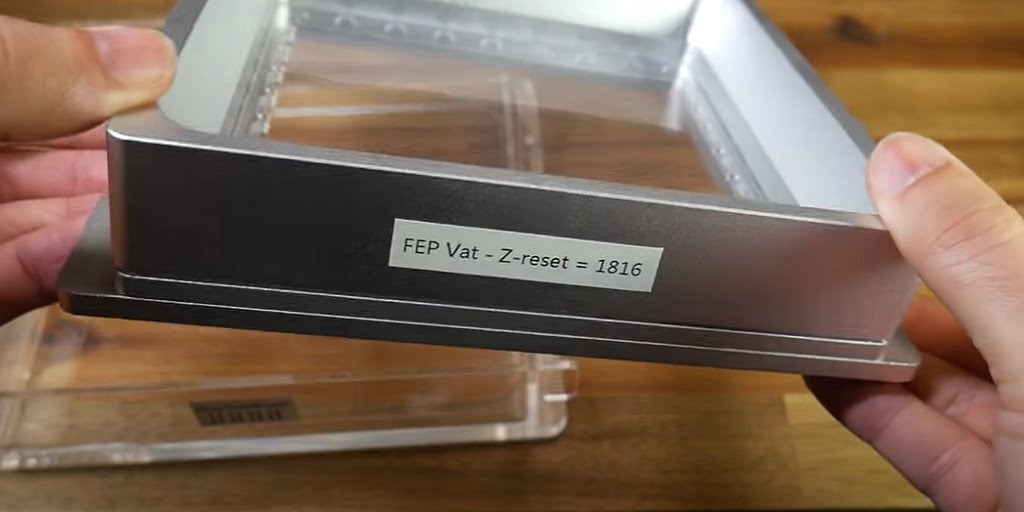

You can print as much as possible on a single build plate or fill up your build plate with the same items. Also, the FEP and LCD filter will wear off less quickly.

Adjusting Prints For Better Speed

If the material to print is flat, then you will have to print fewer layers which will faster the prints and also.

A print speed calculator has been developed to help you choose the right setting based on experimental values.

After Print Cleaning Procedure

Post-Processing is very important in SLA 3D printing and it is good to make it a habitual SLA printing best practice to follow. Wear nitrile gloves while separating and rinsing your 3D model. It will protect your hands from getting exposed to the resin.

The excessive resin can be drained back into the resin tank. Another best way is to squeegee the excess resin off.

Hose out the model in isopropyl alcohol. In the case of a model which is hollow and has drain holes, allow the alcohol to relatively fill the model. Enfold the drain holes, and then gently shake the model to clean on the inside.

It is best to keep the duration very brief. Therefore, circumvent leaving your model for not longer than 10 minutes

Read Instructions Carefully

Give a read to the manufacturer’s manual. The instructions play an important role in the right building, designing, or handling of the prints. Either visit the website or Facebook page to have the best results for your print.

It is very grinding to find the optimal settings for any resin–to–printer pair. A lot of trials and errors are performed. This takes an abundance of time due to several parameters that you can play around with, including the layer width, exposure time, curing time, and special settings for the bottom layers.

Generally, all the data or information comes pre-built into the resin printers

Room Temperature

The high viscidity of resin makes it less runny. So, a temperature between 20-21 degrees Celsius is much favorable. It is best to keep the temperature low only, as it prevents other limitations too.

The layers of a model contract while printing. It causes the bottom edges to move from the build plate. In case of warping, the bed temperature is too low, thus you should take a look at your bed adhesions. An observation was made that if your bed temperature is too high, your model will be like a tortoise plant. It is advisable that you turn down the bed temperature for the next print.

Spare Parts & Resins

As FEP and LCD are considered consumables, then one needs to replace them. The best one can do is to replace the spare parts of these two consumables.

Disposing Off The Waste Liquid

All the residuary uncured resin should be treated as hazardous waste. It includes the surplus resin left in your VAT after printing, support structures that you simply removed, and therefore the not cured resin rinsed off during cleaning.

Plastic sheets, paper towels, empty bottles of resin, failed prints, or gloves contaminated with uncured resin, all of these should be treated in the same manner.

Discard the liquid resin, by eliminating any of its reactive properties simply by curing them fully. Lay all these objects out in the sun and let them fully harden before disposal. It takes about 1-2 days to fully curing the print, depending on the volume of resin in the tank. Cast out the trash according to the local segregation rules.

To get rid of the excessive chemicals is to either wash out or drain them down.

Gaps In Prints

There are various gaps in a 3D print. It’s often due to the over or under extrusion. Make sure to keep notes of the flow rate. Change its value with very small adjustments followed by a test print with each change. Multiple gaps are caused due to insufficient perimeters.

While printing details, some small holes appear around the top and sides of the print. Issues like these can be resolved by slowly increasing the amount that the perimeter overlaps with the infill.

Another problem while producing the infill is the high speed. It will not let the extruded filament stay with the perimeter as the nozzle is moving too quickly for the filament to form a bond. All that you can do is reduce the print speed.

Just don’t go too far, as other problems may arise. There is a possibility of re-orienting your 3D model to ensure it drains correctly during 3D printing, depending on the geometry.

FAQ

The most common problems associated with SLA 3D printing chemicals are allergies, skin exposure, ingestion of fumes, and eye exposure.

Few common things to look for are air bubbles in the resin, bed leveling, filling the build-plate, room temperature, waste liquid disposition, and post-curing of the printed models.

CONCLUSION

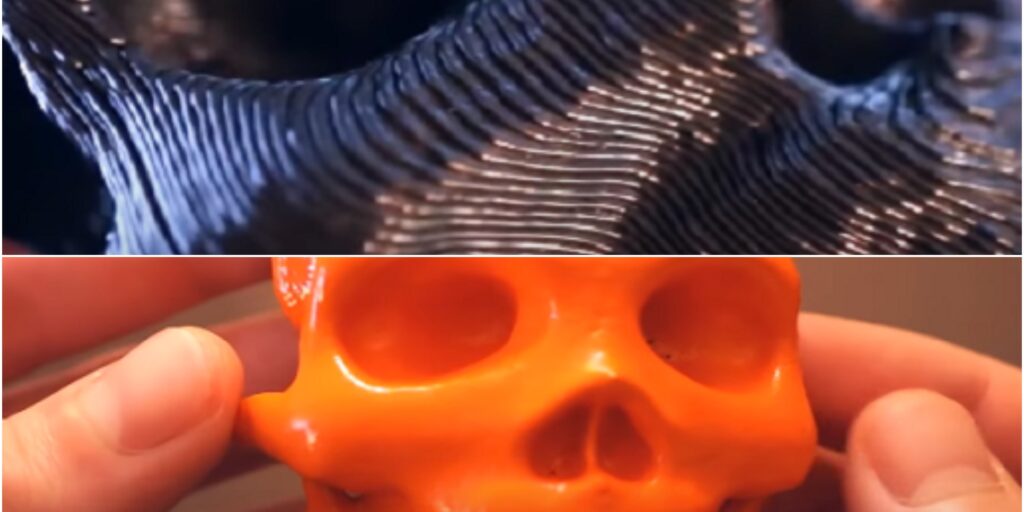

Even though resin printing gives a smoother finished product than filament-based printing, still it is not popular. Besides the higher costs associated with the hardware and the material, the quadric for resin printing is also a lot steeper. While trying with resin printing, it becomes a menace, for those who have no prior knowledge of 3D printing.

There are definite risks associated with using an SLA printer. But all of them are avoidable if you’re taking the proper precautions. And, of course, only use your printer according to the manufacturer’s guidelines. An SLA printer maybe a cool tool to possess for therefore many reasons. And its dangers are far outweighed by its uses, as long as you are diligent and practice safe usage every time you print.

As with any new trade, the simplest thanks to being good at resin printing is to only enter there and provides it an attempt. With the tips we have outlined here, we are hoping that your first time won’t be a catastrophe. Remember, every print is a learning opportunity.