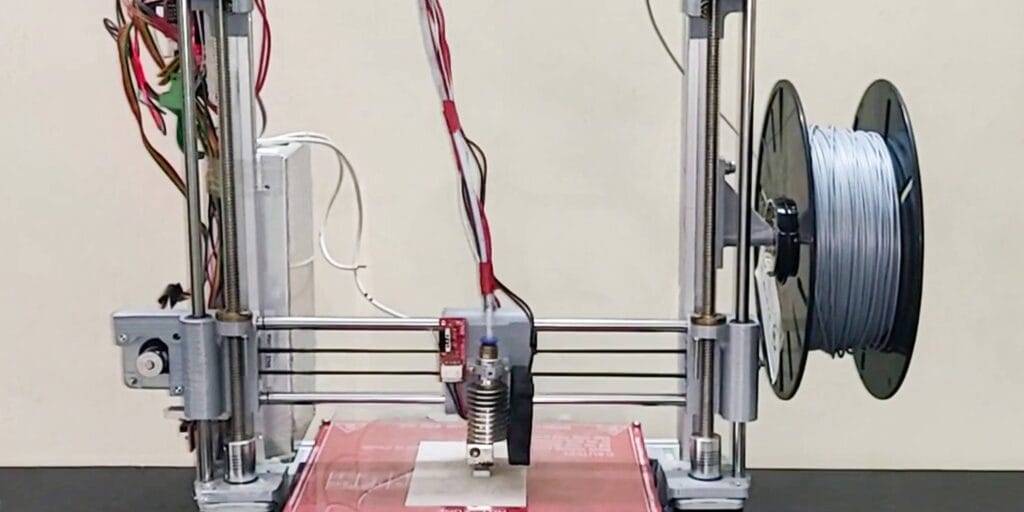

3d printer bed is an essential accessory. As the name suggests that it is a bed that became hot for ease of 3D printing. They are used as a build platform in 3d printers or use as a platform for build platforms. In the market, there are multiple types of 3d printers heat-bed and choosing the right one for you is a difficult task. It becomes easier if you know about the most common 3D printer beds and their uses. So to make your choice easier we are going to discuss some major types and their respective uses.

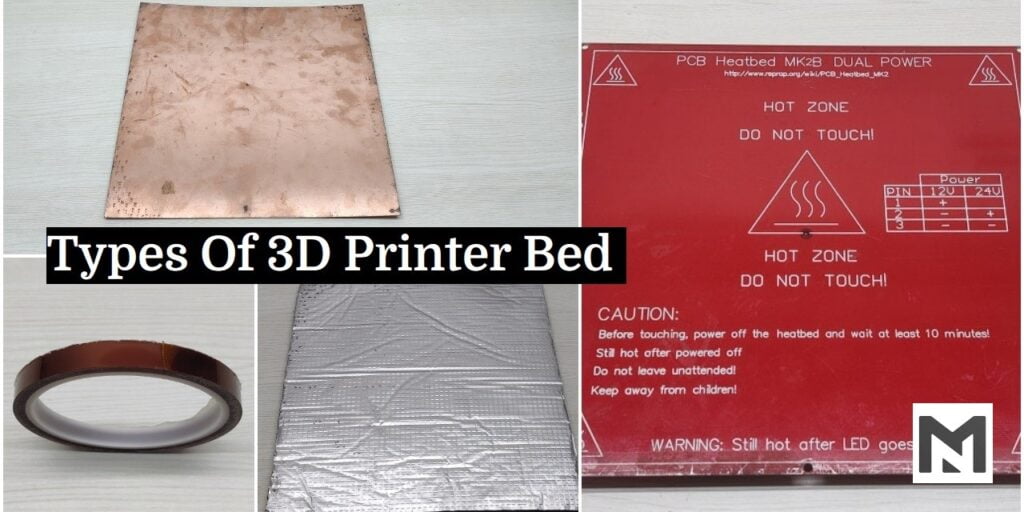

What are the most common heat-bed types? The most common heat-bed types are PCB, Kapton, and Almunium Clad Heater all of them several types depending upon the accessories you use with them. There are many other types of heating beds and some of them are discussed below in the post.

In The Post:-

- 3D Printer Bed Short Intro

- PCB 3D Printer Bed

- Kapton Film Heater 3D Printer Bed

- Aluminium Clad 3D Printer Bed

- 3D Printer Bed Based on Accessories

- DIY Printer Beds

- FAQ For 3D Printer Beds

- Conclusion

3D Printer Bed: Short Intro

When extruder extrudes melted plastic on build surface so due to temperature difference it suffers thermal shock which leads to bad adhesion between printed object and builds surface and also layers are not merged completely. When your model suffers thermal shock so it shows you multiple structural problems which directly affect your model’s physical properties. Sometimes it wraps from the corner and they lift up thus your print is failed.

To overcome all of these problems we use a heat-bed that provides a heated surface for the build the platform so your model is above the heat-deflection point so molten plastic did not suffer thermal shock. Also, it keeps our whole model warm thus adhesion between layers is better.

Some materials require an additional tool with a bed to work best. Frost glass, PVA glue, Paper glue stick, Kapton tape, and Painter’s tape are the additional tools which used with heat-bed for better result.

First, we know about the different types of 3d printer beds.

Types of 3d printer Heatbed

- PCB Heatbed

- Kapton Film Heater

- Aluminium Clad Heater

PCB 3D Printer Bed

PCB heat-bed is the most simple and easy-to-use. It is most common and popular amongst the many types. MK2 heat-bed is mostly referred to as PCB bed commonly. They come with labeled surfaces and soldered less which shows their operational working.

Their structure is very simple. They have fiber sheets with copper traces that form the heating pattern all over the bed. Also, you can also use another material sheet (aluminum, copper, etc.) to build a platform to put it over the heat bed.

Pros and Cons

| Pros | Cons |

|---|---|

| Easy to use | Slow Heating Time. |

| Even Heating | Heat Area is not Controllable |

| Use any other material over it. | |

| Cheap |

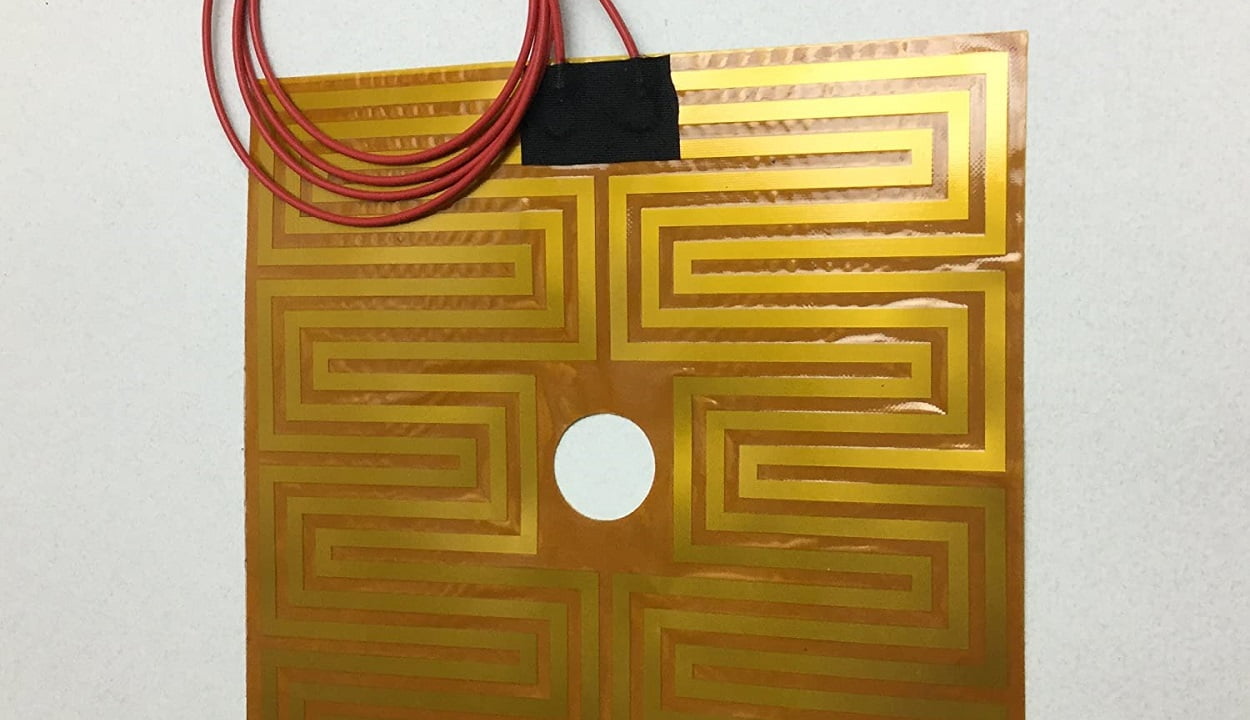

Kapton Film Heater 3D Printer Bed

In Kapton tape Film Heater heating element is a Sandwich between Kapton tape. It provides a high heating rate and uses at higher temperatures. Kapton film heater hotbeds can be found in different variety of shapes. They are very thin and have adhesive below so we can stick them on any build platform

Pros and Cons

| Pros | Cons |

|---|---|

| Fast Heating. | Can not be used raw. (need a secondary plate for solid build platform). |

| Reliable. | Expensive. |

| Very Thin. | Need more safety precautions because high temperature is possible. |

| Presice in Temprature Control. | |

| Long Life Span. |

Aluminium Clad 3D Printer Bed

Aluminium Clad uses high power resistance as a heating element. This resistance is a screw-on aluminum plate. To install this heat-bed it is necessary to use thermal paste between resistance and aluminum plate.

Pros and Cons

| Pros | Cons |

|---|---|

| Controllable Hardware. | Need thermal paste between the clad heater and metal plate. |

| Easy to Customise. | Wiring must satisfy the power consumption limit. |

| The heating rate depends on Power Resister and Input Voltage. | |

| Cheap. |

3d Printer Heat-bed: Accessories

If we use PLA only so we did not require anything with heat-bed because PLA is wrappable but when we use ABS, PC, PTEF, and any other kind of material so we need different bed adhesive for sticking plastic to build the platform. Sometimes people use some accessories and commonly refer to them as a separate 3D printer bed, but they are just above mentioned bed with some accessories. Some of the most common ones used in different heat-beds are.

- Kapton Tape

- PVA Glue

- Painter’s Tape

- Glass

- Metal Sheet

- Ceramic

Kapton Tape

Kapton Tape can handle molten plastic easily. On Kapton tape printed model is easily peeled off without damaging the surface. Also, provide better addition of the model on the bed.

PVA Glue

Regular PVA glue is also useful for increasing your bed surface adhesiveness between model and heat-bed. All you need is to mix PVA glue and Water in a 1:10 Ratio and apply a coat on your bed surface and wait till it dries completely.

But you can also apply a paper glue stick directly on a bed without mixing it in water by just rubbing it on its surface. It is also very easy to clean. If your 3d printed model is stuck on the 3D printer bed then you can use a warm water bath to release the model from the heat bed.

Painter’s Tape

The painter’s tape is coated with wax so applying it on the heatbed provides a better surface grip for the 3d printed model. But it is also not easy to remove the part from the Painter’s Tape surface. Painter’s tape is a cheap and easily available alternative to the Kapton tape. After some prints, you can see that painter’s tape is peeled off in some places so you need to change the tape after some prints.

Metal Sheet

Metal sheets can be used in addition for better results. Most of the metal conducts heat very well thus you got an evenly heated area. But when the metal heats up it expands so if there is no free space for the metal sheet for expanding then it damage your print. When the sheet expands and did not have any free space for expansion then it bowing (Got uneven surface or bends) so it is important to screw only one side of the metal plate forgive free space on another side.

Also, different materials conduct heat at different rates and cool down at different rates which are known as Specific Heat of the Metal. Like Aluminum heat up quicker than Steel and Copper and Cooldown quickly than steel cool because it has low specific heat.

When you print on a metal sheet choose the metal type according to your need If you only use standard PLA filament then an aluminum sheet is better but if you try a different filament then use copper or steel sheet because they have high Specific heat than aluminum. LOW Specific heat metal sheet cool down quickly which gives your ABS Print thermal shock which causes wrapping sometimes.

Glass

Glass On heatbed use very much. Normal frost glass is good for 70oC to 80oC but for higher temperatures, you need to use single pane glass which is expensive but also you can heat up to higher temperatures. For more reliability we can use borosilicate glass. Glass has lower heat conductivity so there is always a risk of heat spots which form on glass thus uneven heating glass will crake to overcome this problem we use a metal sheet with glass for spread heat evenly all over the surface of the glass.

Glass has low heat conductivity which is also useful for us. When the heater of the heatbed turns off the temperature does not drop suddenly but decreases slowly which lowers the risk of thermal shock.

Ceramic Tile

Ceramic is a bad heat conductor it works as an insulation material so it is good if you ceramic tile with a Mains Voltage Silicon Heatbed which gives enough heat to heat up the surface of ceramic tile in less time. The use of ceramic tile overcomes the risk of shattering due to uneven heating. Also, you do not need a special cutting tool to work with ceramic tile. Ceramic also does not conduct electricity so it is safe to use with a mains voltage supply heatbed.

High temperatures for a long time can be maintained easily on the ceramic build platform. Ceramic Low Specific Heat makes it an insulation material so after the turn of a heater of heatbed it cools down firmly so your printed part does not suffer thermal shock.

DIY Type 3D Printer Bed

In this curious world, we can see multiple types of single object credits to our curiosity. Some people use DIY PCB heatbed some use Peltier Module while some use modifies cloth iron as heatbed. So now tell about each of them below:-

DIY PCB 3D Printer Bed

Take Normal Copper Clad board use a laser printer to paste heating pattern design on it or use each sketch to draw the heat element pattern on it by hand then use Ferric Chloride with dilute water (For zero contamination of chemical) to the solution of them and watch the copper board. After etching, you can use this as a normal PCB heatbed but you need to cover it in Kapton Tape for better results and for a good safety level.

NOTE:- Use more the 35-micron copper clad board don’t use copper plating for increasing thickness of cooper trace because after the resistance of trace changes all over the board which causes forming of multiple Heat-Spot.

In this option, you can customize the heating pattern according to your need or if you want to do some experiment with it. PCB Heatbed is easy to install and lightweight which does not force the motor to draw more current for moving it.

Peltier Module as 3d Printer Heatbed

When you want energy-efficient and performance together then Peltier module heatbed is best for because in a single heatbed you can add multiple Peltier module and you control which module has to be active and which have to be reactive while printing. This controllable feature saves a lot of energy because in small area print you need to turn only that area Peltier while in large area print you can use all Peltier modules together.

Peltier module has two sides when you power it up one side became cool while the other side became hot. this happens because it pumps heat from one side to another side. Peltier’s Work on the Thermoelectric effect which discovered by Thomas Seebeck and Jean Peltier in the early 19th century.

The Peltier module is best but if you want to control it firmly then you need to create a circuit that powers all the Peltier modules at once or control them for energy efficiency. If you single large Peltier module then you do not need a complex circuit to control it you use printer controller heatbed DC output also to control it for different temperatures.

Normal Clothes Iron

You can also use clothe iron as heatbed but after some modification. Clothes iron are heavy and their temperature control by their dial. For modification of your iron, you can remove its thermostat and use a solid-state relay for controlling its temperature from the printer board.

NOTE:- Removing thermostat creates a risk of fire and accident because clothes can reach up to 300oC to higher so it is necessary to use good conductivity between the metal plate and iron surface and use all safety measures in printer firmware in case of thermistor fail and use additional safety for protecting your self from Mains Voltage and High Temperatures.

Clothes iron heatbed are very heavy which put too much load on motor and driver which cause to overheating of them so it good if you use them with stationary( That don’t move ) build a platform so your motor and driver be cool. Stationery Build platform printers are Delta, SCARA.

CoreXY printer also supports heavy load but only when you use good thread rod because under heavy load thread rod nut slip from threads and cause problems. Even Modified cartesian printers also support heavy load but need to use overpower stepper motor and driver which create complexity in your printer.

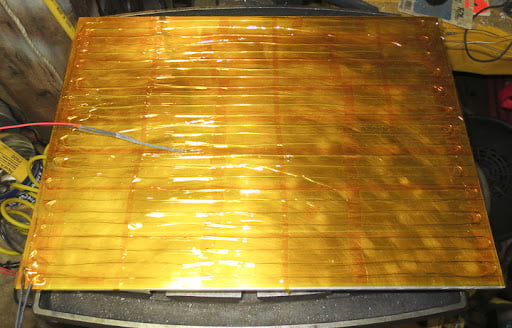

Nichrome Wire Heatbed

Nichrome wire is a popular heating element which mostly uses in clothes iron. we can use a nichrome wire loop and Kapton tape to form a flexible large heating element then place this heating element below the metal plate to complete the heatbed. It is not solderable so you need to make a direct connection with power inputs. We can use a screw terminal connector for connection. While making a sandwich of Kapton tape and nichrome wire make sure loops of nichrome wire will not short themself also measure the resistance of the total nichrome wire. Resistance should not be more than 8 ohms or less than 6 ohms.

If the resistance of the total nichrome wire is very high then separate it into parallel units and use solid single strand wire to power them. Connect steel wire to screw terminal and connect power input cable in screw terminal.

NOTE:- Use of Kapton Tape is necessary to avoid any problem because Kapton tape exile high temperature so it decreases the risk of an accident and fire.

Insulation is Required or Not for different types of 3d printer heatbed?

In the above section, we learned about many different ways to heat up the bedfast now, we will learn about how to keep them there by using insulation.

While printing on one side of the heatbed the other side of the heatbed heater is naked and also became hot as upper surface except for the Peltier heatbed but if we insulate the bottom part of the heatbed thus we can maintain our heatbed temperature more firmly. To do this, we use different methods to insulate the heatbed from below. These methods are using Aluminium Adhesive Mat, Cork Sheet, Plumber’s Felt, Cardboard, or even use Encloser to heat up the whole unit.

Aluminium Adhesive Mat

This is Foam sheet really works well when you need to keep your heatbed temperature stable. This foam can handle 50oC to 150oC heat. It is easy to install it on the bottom of the heatbed heater. First, clean the bottom of the heatbed heater then peel the adhesive backing from the foam and stick the foam on the heater bottom. This insulation decrease the heating time of the heatbed.

Cork Sheet

A cork sheet is a very cheap and effective option for heatbed insulation. It has multiple microscopic air bubbles so it works well as an insulation material. You can add a cork sheet at bottom of the heatbed by the screw or tape it works. For better performance, you can cover the outer part of the cork sheet with an aluminum sheet and Kapton tape.

While Preheating you can use another cork to put it on the upper build platform for fast heating but this method did not work always because when you remove the upper cork sheet the cold air of the room give the thermal shock to the heatbed thus heatbed temperature drop few numbers( It depends on surrounding environment).

Plumber’s Felt Insulation

Whenever people doing metal welding and brazing they use insulation sheet to protect ourself from the extreme heat of the welding machine. Thus it can we also use it as heatbed insulation.

FAQ For 3D Printer Beds

Which is the most common type of 3D printer bed?

The most common type of 3D printer bed is PCB Heat Bed. It is very easy to use and maintenance is also very simple.

What are some major types of 3D printer bed accessories?

Some major types of 3D printer bed accessories are Pelton Tape, Painter’s Tape, Metal Sheets, and Glass Sheet. There are other accessories also which can be used to further categorize 3D printer beds into sub-categories.

Conclusion

In this long article, we tell about different types of heat beds, Which surface is best with it and give the best result in combination but there are a lot more It depends on you for choosing heatbed. If you live in cold areas then ALuminium clad and Silicon Heater heatbed with insulation is best for you but if you live where the weather is warm then PCB and aluminum clad heater is best.

Although if you want to do experiments or want to make some energy-efficient and fast then you can also make Custom Peltier module Heatbed. on which you can control the heating area too for better efficiency.