In this post, we are going to talk about the personal tips & tricks that we acquired and learned over time regarding the safety of working with FDM 3D printers.

3D Printers are the tool through which we can make our imaginations true. These are the tools by which we can literally print our thoughts and expand our creativity. But, with everything, some precautions are necessary.

In FDM 3D Printers there are few things that you should always keep in mind while working with it. If you ignore it, it may give you something (Shock, Burn, etc.) to remember.

FDM printing precautions to be taken are, always ground your FDM printer, keep your kids away from 3D printers, and always use force on scrapers away from your body (explained in the post).

Below are the few most important precautions that everyone should take to make FDM printing safe and enjoyable. Also, always remember to perform calibration printing for the FDM 3D printer if you are using it the first time to know its best printing settings.

Burn Risks (HeatBed, Nozzle)

Hot-End

FDM (Fused Deposition Modelling) basics are based on melting the filament and then depositing it layer by layer making our model. To melt the filament i.e. mainly plastic the hot-end reaches the temperature up to 300 oC. Although the temperature range depends upon the filament being used, the general range of temperature lies between 190 oC- 300 oC.

This temperature is hot enough to easily burn on contact. Our teammates have many times experienced these burns and we could testify that the hot-end is not something you want to play with.

Especially, if you have children around then you should keep it out of their range.

Heat Bed

Another thing that you should be cautious with is the heat bed. In both parts, the name is enough to indicate their functioning. Although the heat bed doesn’t get as warm as the hot-end still it is dangerous enough to be cautious. The heat bed is used to increase the surface temperature and make it perfect for the extruded layer to stick on.

Solutions to Minimize Burn Risks in FDM 3D Printer

To minimize the burn risks you could use the temperature indicators on the screen. This way you can know that whether it’s safe to touch the heat bed or hot-end to do some work. But, this method will not work with your little ones and pets as they understand the risks, the best answer then is to use enclosures.

Currently, there are many 3D printers that are coming with enclosures. The enclosures are easy to remove and then again put on while printing. You can also 3D print an enclosure yourself with your own 3D printer at home. You can print its frame and use Acrylic panels to enclose it. Printing an enclosure at home will be the most budget-friendly option. It is also best if you already have a 3D printer without an enclosure.

If you are thinking to buy an FDM 3D printer with an enclosure you can look into the options given below. We have included the best option for each category i.e. budget-friendly, best overall, and top-selling.

Budget-Friendly: FDM 3D Printer with an Enclosure – FlashForge Adventurer 3 Lite FDM 3D Printer (Amazon.com)

Best Overall: FDM 3D Printer with an Enclosure – UP! Mini 2 (Amazon.com)

Top Selling: FDM 3D Printer with an Enclosure – R QIDI TECHNOLOGY (Amazon.com)

Scraper Blades

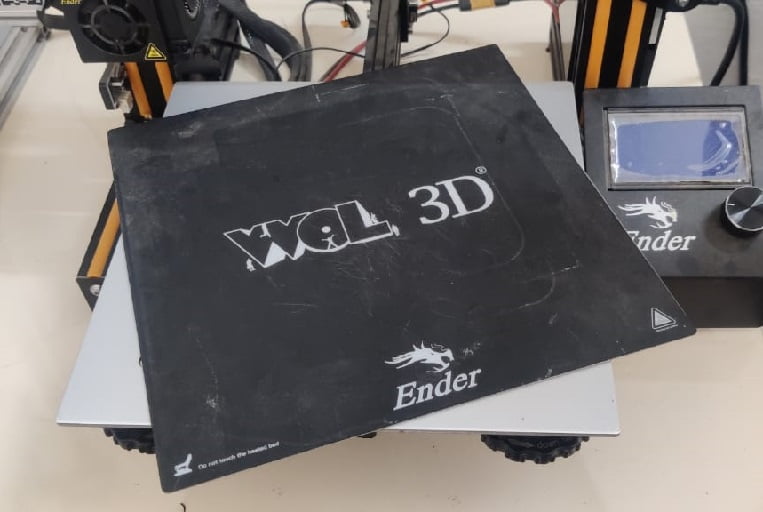

Scraper blades are scary-looking tools that are used to remove printed models from the heat bed. Many 3D printers require these scraper blades as they use a slightly higher temperature for bed layer adhesion on the heat bed. This higher temperature helps in securing the base layer at the position and prevents it from other faults like warping etc.

Although using scraper blades should be quite simple but there are many people who hurt themselves while using them. We can remove the prints from the heat bed by forcing them with the blade.

But, while using the force be alert not to put your other hand in front of the line of force. Many people put their other hand in front unconsciously and sometimes the blade slips and hurt them very badly.

Remember to always use the blade away from you and keeping your hand safe from the slip. There is another alternative that is used in the latest 3D printers i.e. a removable print surface. You can also purchase these print surfaces as an add-on later.

These removable print surfaces are flexible and thus printed model can be easily removed by flexing the surface. We are listing our favorite flexible print surface add-on to buy if you already have a 3D printer.

Creality Original Ultra Flexible Removable Magnetic 3D Printer Build Surface – Heated Bed Cover for Ender 3/Ender 3 pro/Ender 5 3D Printer 235X235MM

Short-Circuit

Every now and then we get the zapping sensation of these electric shocks from our different-different 3D printers. All the time the fault is pretty easy to identify and rectify.

The main cause of getting an electrical shock is that your 3D printer is not grounded properly. We know that 3D printers are electrical equipment and take AC current as an input power source. Although the power unit attached to the 3D printer converts the AC input to DC input for printer parts.

Still, AC input could run through the printer’s body and create a potential difference which when touched could give heavy shocks. Our Homemade 3D printer uses RAMPS 1.4 as the power board which converts live AC current into 12 Volt, 20 Amp DC current, while the 3D printer in the market use 24 Volts as the converted voltage.

The main problem is that most power hub is made of metal and all the wires from AC come into them and then they convert it to DC and transfer to several parts of the printer. During this process, there is the possibility that any live wire gets loose in the future or it may have been loosely tightened. This loose wire could touch the metal body of the power supply and induce a high voltage in the body of the printer.

When there is potential in the printer body and you touch it the circuit gets completed because you are touching the ground also and you experience a shock.

Although nowadays most of the power supply is made of plastic and you don’t need to do anything but if you have that metal body power supply (image below), then please do consider grounding your 3D printer.

FAQ – FDM 3D Printer Safety

There are four major safety precautions that should always be kept in mind while FDM 3D printing i.e. Burns, Shocks, Pinching, and Scraper Blades.

Scraper Blades are the most dangerous things from which you can be hurt very badly. If you don’t use them in the right way then they can cause minor injuries and infections to severe injuries which will require doctor cosultancy.

To keep children and pets safe from burn injuries while performing FDM 3D Printing you will need a 3D printer enclosure. These enclosures are nowadays already provided with most of the 3D printers, but you can still build one easily in your home.

Conclusion

All technologies in the world come with some precautions that should always be followed. Similarly in FDM 3D, you should vary of shocks, burns, etc. You should always do regular checkups for loose wires, nuts, and parts that could break-in time.

Following safety practices is a good printing practice and one should never ignore them.

If you want to know anything else about FDM 3D printers related risks then please use the comment box.

Thank You.