Resin printing is also known as stereolithography (SLA). Resin Printing is the first additive manufacturing method that lays the foundation of 3d Printing. Different from other methods resin printing uses a Light-sensitive chemical that becomes solid when expose to a particular wavelength of light. Like some chemicals are UV sensitive while some are sensitive to regular visible light. This is a simple process of making parts but people often ask why is resin printing is expensive.

Due to the use of different technology in resin printing, the cost of resin printing is higher than FDM printing. Also, Resin that is used as an additive material is expensive. Most cheap resin printers use a UV laser to form a 2d image of the model. This method is cheap but does not give high detail print while other high detail resin printers use a high-resolution LCD for a 2d image with a UV light source below them.

In The Post:-

- Stereolithography: Working

- Causes of Expensive Resin Printing

- Different Methods of Resin Printing

- New Initiatives

- FAQ

- Conclusion

Stereolithography: Working

How does an SLA 3D Printer work? In stereolithography, we use a light-sensitive chemical and a constant source of light. When these chemicals expose to UV light so they create a long chain of polymers which results in the solidification of the liquid. This reaction outcome depends on the mix of the chemical or which types of light rays are used with it.

Resin Printer uses a light source to form a 2d image of the model. This image is formed in the light-sensitive chemical on the platform which is dip into the light-sensitive chemical tank. We use a UV laser to produce a 2d image of the model on the platform or use a Transparent LCD with UV Light under it to form a complete 2d image.

With an LCD mask, we form the model image at once on the platform is in the chemical tank. For each layer, we pull up the platform according to the required layer height. Doing the same process multiple times for every layer in end we get a 3d model of our virtual 3d model.

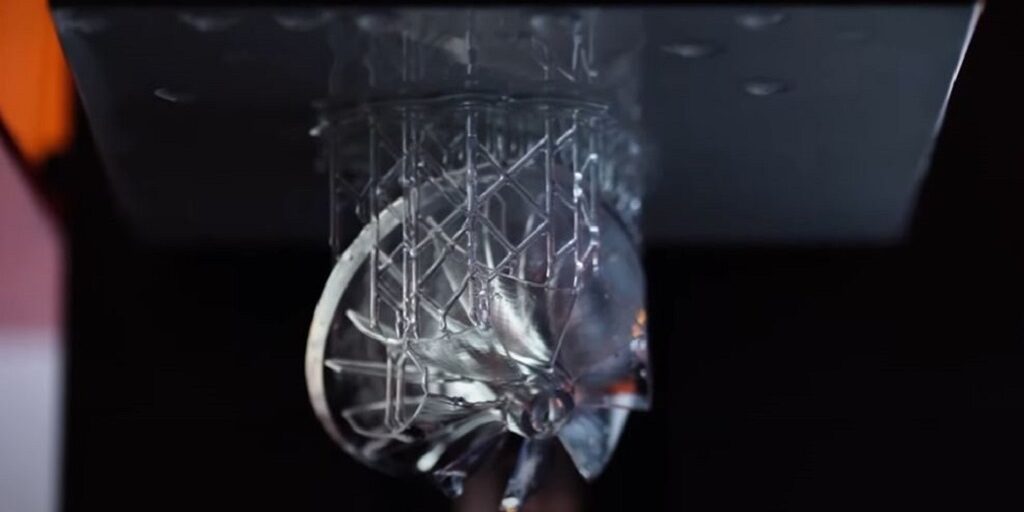

With resin printer, we create a complex design part which is not possible with current methods, for example, we can see that a car company create high-speed brake calipers with 3d printing which has a unique topology for better absorption of the braking force. Also, we can create parts that have internal designs varying on the different heights of the part.

Causes of Expensive Resin Printing

Technology is one factor that increases the cost of the resin printer but there are many more factors that increase the cost of the resin printer.

- High quality resin are expensive

- Required multiple time Post Processing after print

- Resin print are not recyclable

Expensive Resin

Resin is expensive because their raw material is expensive but also their manufacturing process is complex. SLA resin comes in a wide variety of the material. They have different thermal and mechanical properties. Also, some have other properties like Magnetic, non-electric-conducting, and anti-static while they also come in a mix of multiple elements to full fill your desire. Like:- Metal printing resin, Ceramic printing resin, and flexibility. These resin give you a complete feel of true elements but they require post-processing.

Resin printer output quality also depends on the resin which you use with it. Most of the cheap resin does not give you satisfactory results. But high-grade resin with a good resin printer gives you the perfect print. Currently, medium grade resin cost you 40$ or high-grade resin cost you above 150$. These are for only regular resin but there are more types of resin which are used in Engineering, Medical and Industrial field cost higher than regular ones. So you know resin printing is expensive because also resin is expensive.

Post Processing

When your resin printer completes the printing process. Then you need to do some more steps for getting a complete usable print. After finishing printing you got your 3d model, but it is wet with sticky resin so you need to clean it before do any other process. In the case of regular resin after print successfully you need to cure your print with isopropyl alcohol or some resin will be wash with water only. Some resins are too sticky. So you need an ultrasonic bath only for some. But you can also use water-alcohol mix and put it in UV light for complete curing.

For some industrial type resin, you need a furnace or sander. In the case of ceramic print, you got a print model which has 30% resin and 70% ceramic powder so you need to vaporize the resin and bind the ceramic powder. For this process, you need a temperature control furnace which able to perform the thermal cycle at the correct temperature. After the complete thermal cycle, you got your complete ceramic print which can withstand in front of high temperatures.

For metal type resin you also need the same furnace but with high temperature because metal required high temperatures. although all the process is same as the ceramic one, at last, you need a sander to sand your print if they required for a glossy finish.

As you see for post-processing you need additional chemical and equipment to cure you 3d printed model these material and machine cost you high which increase your resin printing cost. But they also give you satisfactory results.

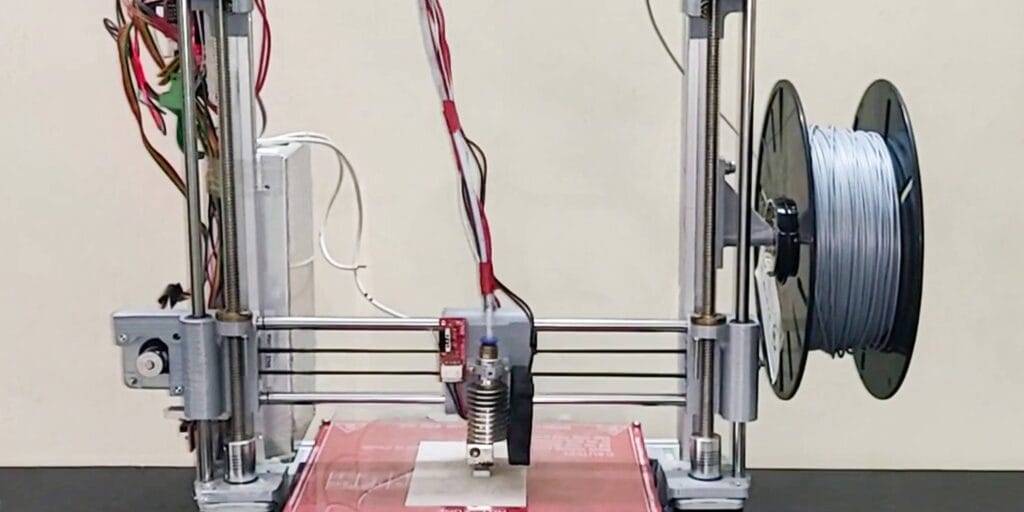

Not Recyclable – Currently

If you want to recycle your resin printed part then you will not find a lot about it because currently no method available which allow you to recycle the printed part. In FDM Printer you can recycle your failed print or finish print. On the internet there are multiple DIY and buy versions of filament extruders, they recycle your 3d print into new filament. For SLA printing Yes there is something that you can do, dispose of your resin after UV exposure also recycle the isopropyl alcohol from curing but the printed part can not be recycled. Many researchers work hard to solve this problem until then use your resin printer only in the necessary situations.

If we were able to make recyclable resin then the price of the resin must be dropped and it becomes quite easy and affordable to create high details and strong with resin print which reduces the resin printing expensive cost.

Different Methods of Resin Printing

SLA printers use multiple different methods to print 3d models from resin. These methods also decide the pricing of the SLA 3D Printer. Here we about these methods below:-

- UV Laser image formation

- Using transparent LCD as Mask

- DLP Light Projector

- High Resulution transparent Display

- Continuous Liquid Interface Production

UV Laser Image Formation

In UV Laser image formation high-power UV laser is used as a light source which is in a form of the point. This laser pointer is reflected by two motorized mirrors are used for moving the laser pointer on the glass tank bed. These motorized mirrors move the laser pointer. Thus they form a single layer 2d image of the model on the bed. Where the laser exposes to the resin that part of the resin becomes solid.

After this build platform rises up a little extra. (They do this to ensure that space between the glass window and the previous build layer is filled by new resin). Then comes back to the next layer’s required height. These steps repeat multiple times to produce a complete 3d model.

Laser image formation is a cheap and simple method so the cost of this type of printer is low. It uses a laser which takes little time to produce a complete image on the build surface. So this method is slow but prints fast than FDM. But it has many things which you have to deal with when you use this. You need to calibrate the motorized mirror before using it.

When you use or change to new laser you need to adjust the focus of the laser, if your laser has beam deformation then it produces multiple solidify particle of the resin in the tank which ruins your print also waste your resin.

Transparent LCD MASK

It only has a movable build platform that can do motion only for increasing or reducing height. For image formation, on the build platform, this method uses transparent LCD with UV light below. In the process, LCD creates the image on it. Where the area has to be exposed to UV light their pixel does not activate while the area which has not to exposed to the light their pixel activated.

UV light only goes through the area where a pixel is not activated. When UV light exposes to the chemical then it became solid. After that build platform does a maneuver to increase the height for the next layer. Also, it does an up-down motion to fill the space between the build platform and the glass window.

In this method, the whole image produces at once so the speed is higher than the laser resin printer. Also, it uses an LCD mask which minimizes the light deflection in the resin which does not waste your resin. For a more even finish it use a light diffusion mirror over the UV light source to spread the UV light evenly on the build platform. These printers also have a low cost but it depends on their resolution.

DLP Resin Printing

As we know about the DLP projector has High power light source and transparent LCD. This creates the image which has to be projected then High power light goes through the transparent LCD and multiple lenses to project the perfect image on the projection screen. The same method is used by the DLP Resin printer. Instead of a High Power Light source, it replaces it with the High power UV light source and the display is replaced with monochrome if required.

DLP resin printer has two types. In the first one (1) Image of the DLP projector reflect by the mirror on the build platform while the second kind (2) directly projects the image From the DLP projector. Then this UV DLP projects the image of the single layer on the build platform and repeats the same steps for further process. After that, we got the complete 3d model.

DLP’s working process is the same as the LCD mask process. But the DLP resin printer has more resolution than the LCD mask method. This method increases the surface quality of the print because as higher the resolution we have for producing images as high the surface finish we get.

If we increasing the image size produced by the DLP projector then the resolution decreases but if we decrease the image size produce by the DLP projector then the resolution of the printer became high.

High Resolution Transparent Display

This process is the same as the LCD mask process except it has a high-resolution transparent display which allows the user to print very high details print without compromising with the print area. It gives you a very detailed print. This high-resolution LCD panel is very expensive which is also one of the major causes of expensive resin printing.

Currently, in the market Phrozen, Sonic Mega 8K has a monochrome 8k display. These high-resolution displays have very high costs which increase the overall cost of the resin printer but also give you high-resolution print.

Continuous Liquid Interface Method

It has the same process as the LCD mask printer has but it membrane between the build platform and LCD glass. This allows the resin to fill the space instantly between glass and the build platform when the build platform increases its height. Thus build a platform does not require going up and down to fill the space, this process saves time and increases print speed.

Now Carbon 3D has a patent for this process. Their printer uses this membrane call a dead zone which did not stick the resin to the glass window. So the resin flows smoothly and fills all space which allows the printer to do continuous printing.

New Initiatives

Here is some good stuff that Lawrence Berkeley National Laboratory in California, Researchers seem to discover a way to easily recover thermosets or at least one specific mixture they have devised. They call this a “Closed Loop Polymer Cycle”.

Recyclable Photopolymers

The catch here is that these research resins are not photopolymer resins, which are the specific type of material used in SLA and similar 3D printing processes. These resins are specifically designed to solidify (polymerize) when exposed to certain frequencies of light, typically matching the laser light’s frequency in a 3D printer.

I’m no chemist, but I’m wondering if it is theoretically possible to devise a photopolymer version of this recyclable thermoset resin? If this could be achieved, then we could see a new form of recycling in 3D printing for resin equipment.

Perhaps this is chemically impossible, but if it is possible, it might be an interesting development. While the number of individual resin 3D printers is today relatively small, it’s quite possible we may see the emergence of vast factories full of resin 3D printing equipment in future years. Such operations would generate a considerable amount of waste unless we had a thermoset recycling program based on this research.

FAQ

What is the main factor that makes resin printing expensive?

The main reason behind resin printing being expensive is the cost of the resin itself. They cost around $50 per liter which is a lot for some of us.

What are the factors which determine the cost of running an SLA printer?

The cost of running an SLA printer depends upon the various factors some major of them is the cost of Resin (raw material), maintenance cost, post-processing, etc.

Conclusion

After this long reading, you get to know that why resin printing is expensive. It has many factors that increase or decrease the cost of resin 3d printing. Technology that is used in resin printing or its design also affects its cost. 3d printing is not quite new to this world but it requires more research on it. In previous years we saw multiple innovations in 3d printing also in the field of resin 3d printing. Yes, it is true that it just beginning more work has to do and more innovation has to come.