You already know the wonders of using flexible filaments. They exhibit the property of shock absorption and restoration to original shape when twisted. However, printing your designs with flexible filament is relatively difficult. Among many challenges flexible filament is posing, one is the flexible filament warping.

This detailed guide will address the reasons and propose optimal solutions to avoid the flexible filament warping issue. But before discussing it, we must understand what ‘Warping’ actually stands for in 3D printing.

What is Flexible Filament Warping? It is the deformation of shape or a portion of the print. It usually occurs when flexible material shrinks while printing. During 3D print, the material expands at first before contracting upon cooling. If the contraction is too much, then this causes the print to bend up from the bottom.

A Myriad of reasons is responsible for this. Let’s discuss them one by one, along with the best solutions.

In The Post-

- Reasons & Solutions of Flexible Filament Warping

- FAQ | Flexible Filament Warping

- Conclusion

Reasons and Solutions of Flexible Filament Warping

Dryness of Flexible Filament

Reason:

One of the prevalent reasons for flexible filament warping is to start printing without drying the spool of filament. Water pockets in the filament promptly turn into steam as soon as they hit the nozzle. Steam leaves the voids and excessive stringing in design.

Solution:

Use a conventional oven to dry the flexible filament at 135°F for 6 hours. Leave the oven to cool down at ambient temperature. If you intend to use a vacuum oven, dry filament for half an hour to an hour. PrintDry can also be used to keep the filament dry.

There are several other methods that you can use to remove excess moisture from the flexible filament, see our post on How to dry flexible filament?

Initial Layer Settings

Reason:

Flexible filament warping might also occur because of flawed initial layer settings. Three crucial factors are to be checked in settings. First is the initial layer height, second is the initial layer speed, and third is the leveling of the print surface.

Solution:

You may require steps to make your first layer stick to the printing bed. First, level your printing surface. Adjust the Z-offset set to a suitable height. If the material is not sticking, use plenty of Squish to the flexible filament. Also, slow down the initial layer speed to make the filament fixed to the build plate only.

There are various other settings besides initial layer settings that you may have to double-check to have a perfect 3D print with flexible filament without warping. Check out our post on Flexible Filament printer settings for the best 3D print.

Printing on Blue Painters Tape

Reason:

Poor use of blue painter’s tape can also cause flexible filament warping. Designers usually set high bed temperatures. It causes the tape to develop more than desired strong bonding with the printed part. Using the same tape strips repeatedly for tens of prints is equally responsible for warping.

Solution:

Layer the tape strips line up edge to edge. Most flexible filament does a great job at a bed temperature range between 55°C to 65°C. Also, change the tape after every 5-10 prints. Any damaged blue tape strip needs to be replaced before printing. If you face a problem with low stickiness, use a PVA glue stick.

Printing on Glass with Heated Bed

Reason:

Print adhesion becomes weak when we don’t use a clean and smooth print surface. The presence of a minute amount of oil or grease on the surface will lead to poor adherence to printing objects on the plate. It will eventually lead to worsening filament warping.

Solution:

Use the glass bed because it is usually smooth and easily cleanable. You should have a temperature-controlled bed. The recommended temperature is dependent on the type of flexible filament you are using, from room temperature to 110°C. Apply the PVA glue to ensure the stickiness of flexible filaments throughout the 3D printing process.

Extruder Temperature

Reason:

Sometimes, the extruder temperature is set too high. It will leave the strings between the different parts of the print. Conversely, when the extruder temperature is set too low, the filament will not be adequately melted, and plastic will face flowing difficulty. Resultantly, you will get sparse layers that will leave the infill not connected properly with perimeters.

Solution:

To adjust the optimal temperature, incrementally lower it by 5°C if you have set it too high. Similarly, an incremental increase of 5°C is recommended if you have mistakenly set the temperature too low. However, you must ensure that the temperature is high enough to melt the filament sufficiently. Gradually taking the temperature up to 255°C can avoid flexible filament warping.

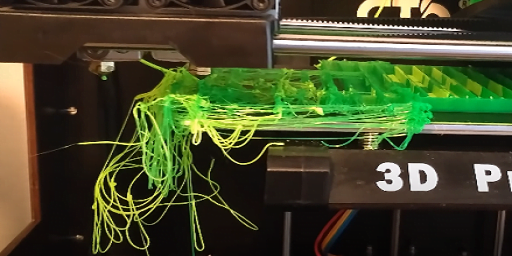

Printing Speed

Reason:

Check the printing speed if you face a warping problem while 3D printing using flexible filament. If the speed is too fast, it will cause under extrusion, and the design infill will look like a spider web. It will also make the material get attached around the nozzle and drag along it on the design surface.

Solution:

There are two possible solutions to ward off this problem. The first is the straightforward way. Just slow down your printing speed. However, if you want to print at a fast pace, you must upgrade your existing extruder to a stronger one. Don’t forget to replace the motor accordingly.

FAQ | Flexible Filament Warping

There are many points to look at if you are facing warping some major of them are extruder speed, bed alignment, printer settings, heat bed settings, etc.

Flexible filament warping could be minimalized by using Blue Painter’s Tape. It is used to stick the base lower to the bed so that further layers above it are stable and warping could be stopped to some extent.

Conclusion

We hope that after reading this guide, you will be able to print the objects using flexible filament without any warping problems. Implement the solutions and let us know how much they are helpful for you.

If you have any queries or suggestions regarding flexible filament warping then use the comment box below. Thank You.