What are the major differences between SLA printers and SLS printers? This question arises in the mind of every 3D printer enthusiast. Both of them have their own merits and demerits and their own applications. To give you a detailed idea of them we will discuss the practical things in this post. We will willingly skip the specifications and other theoretical details which you can find on their respective official web pages.

What is the main difference in the working mechanism of SLA and SLA printing? In SLA printing we use liquid resin, made of polymers which becomes solid when exposed to UV light, while in SLS printing we use powder of polymers which are sintered (bind) together with the help of high power laser. This is the major technological difference between the SLA printer and the SLS printer there are many other differences which we will discuss in the post below.

To get a complete difference we are going to look at all the major aspects of both printing technologies

- Printing Methodolgy

- Post-Processing Methods

- Recycling

- Applications

- Cost of Printing

- Miscellaneous Differences

- Conclusion

Printing Methodology

Both SLA and SLS printers use additive manufacturing processes to create 3d models from materials. Although they use the same technology the methods of application are different.

SLA Printer

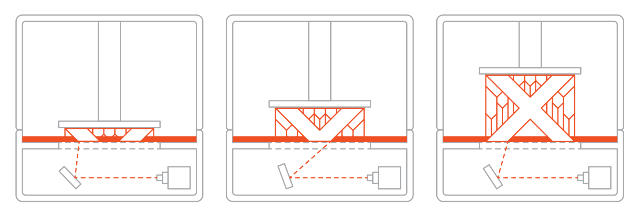

SLA printers use light-sensitive resin, when the resin is exposed to UV light it becomes solid. The SLA printer has a transparent monochrome LCD with UV light under it. A transparent tank is placed upon the LCD which consists of resin.

Its build surface is a flat metal plate that is only movable on Z-axis(up and down). When a user starts to print the Build platform comes down and submerged into the tank to its bottom after that transparent LCD creates a negative image then UV light under the LCD display glow.

UV can pass through LCD where the pixel is not activated thus that area resin became solid. For the next Layer build platform increase, its height is according to the required layer height and LCD creates the next layer image. After that UV light turns on again and solidifies the resin. This whole process repeats until the complete 3D model is created.

You can visit our blog for Best SLA Printing Practices for Perfect 3D prints.

SLS Printer

SLS printer is known as Selective Laser Sintering printer. The working of an SLS printer is pretty straight, polymers powder are used as an additive material for the manufacturing process. These powder particles are bound together with help of a high-power laser. The SLS printer has a flatbed and roller with nozzles that spread and level the powder all over the printer bed. At top of the build chamber, it has a high-power laser whose pointer is controlled by two motorized mirrors.

Also, it has a heater in the bed for pre-heating the polymer powder. For printing, the heater pre-heats the powder, this preheating makes sure that warping is minimal. It also makes powder stable when a high-power laser dumps energy on it.

After pre-heating a roller applies polymer powder all over the bed if the bed is empty in preheating then apply powder on it. Next, a high-power laser traces the layer on the polymer powder. This laser melts the polymer’s particles and binds them together.

For the next layer again roller level the bed surface and spread the even coat of powder on it then laser draw the layer image on it. This process repeats until a complete 3d model is created.

Visit the following link to know more about SLS Printer Working in Detail.

Post-Processing Methods

SLA printing vs SLS printed parts both require different post-processing after print. This post-processing method depends on the material type used for the process and surface finish type. They are very necessary for strength, finishing, etc.

SLA Print

SLA printed parts need to be cleaned before use or they require some additional process to make them useful. This additional process depends on the material type which is used in the printing. If you are using regular resin then you need to wash them with water and isopropyl solution. After that, you need to cure them under UV light or you can also use sunlight for this.

If you use some industrial resin-like Ceramic one then after a print you need to vaporize the resin and bind the ceramic particles together. To do this you need a temperature control furnace that performs a thermal cycle. After this cycle, your print is a solid piece of ceramic but decreases in size because the resin is vaporized and ceramic is only left.

If your printed model has support then you need to remove the support material after this if you need an even surface finish then you can use sandpaper for this, although SLA printers already have very smooth 3D prints.

SLS Print

In the SLS printer, 3d printed model is between unfused (unbind) polymers powder so when you take out your print you need to clean the excess powder. This excess powder can be removed with the help of a vibration table or with air blasting. But if you use air blasting then you will just waste some of your excess powder. In the vibration table, you can collect excess powder and reuse it. This vibration can be also ultrasonic type.

Due to being covered with unfused polymers particles during fusing by laser. This 3d printed model surface became grainy. So you can use medium Plastic bead blasting or medium tumbling to make the surface smooth.

As we tell you the SLS printed part has inherent water resistance but the additional coating can enhance it. Silicon and vinyl acrylates have been shown to provide the best result but for complete waterproof coating, the dip method is best. You can also electroplate your SLS printed 3d model as your requirements.

Note:- Model with fine details can not be used with medium tumbling.

Recycling

SLA Printed Part

Currently, no exact method exists which can recycle your SLA printed part back to liquid resin. There is heavy resin going in the direction and we will update as soon as any significant procedure some out.

The main problem with SLA printing is that most of the resins are thermosetting polymers thus they can’t be easily reversed back.

SLS Printed Part

SLS printed part also cannot be recycled but excess powder degrades could be used but after some refinements and adding additional elements. We can also use excess powder without any refinements but this will decrease the 3d model’s mechanical and thermal properties so to keep these properties the same we need to do these refinements.

Applications

SLA Printer

Most SLA printers use for modeling, casting, and for prototyping. As the resolution of the LCD increases the fine detail print you can get from the SLA printer. They are most popular for their ability to print miniatures in great detail. You can easily print 3D models of a few millimeters without any difficulty.

Also, they are famous for their smoothness thus they are mainly preferred for presentation purposes.

SLS Printer

SLS printers are used for End-use production in batches. If you want to start your own manufacturing unit so you choose an SLS printer because it can do the job with robustness. You do not need to waste your raw material as support because unfused power in the SLS printer provides the support for parts.

The 3D models made are very sturdy and it is mainly preferred for industrial prototyping, i.e. those prototypes which are used for performing tests and experiments.

Cost of Printing

SLA Printer

Desktop SLA printer comes in a wide variety of price range. This price range depends on the type of printer and the type of area where it has to be used. If you are a beginner or just want to print some experiment stuff or project stuff then you got an SLA printer of 300$ with a small print platform. Professional SLA printers start from 3500$ and if you increase print platform size then it would go to 10,000$ and more. Industrial SLA printer which can print on a large scale without and break can cost up to 80,000$.

For the SLA printer, you need Resin from which your 3d model was created. Normal use resin will cost you 40$ per Kg it’s mechanical and thermal properties are good but it does not give you a high-quality surface finish. For good quality resin, you have to spend 140$ – 160$ per Kg. While Industrial resin will cost you more.

SLA print required cleaning after print because the resin is sticky which sticks all over your print. For cleaning resin print there are multiple ways. Also, you can find special tools in the market which automated this process if you want but increase the cost of the print. Some resin print also needs post-processing after print thus it will increase the print cost but this process depends on the material type.

SLS Printer

How budget-friendly are SLS 3D printers? SLS printers are not for hobby works because they have large sizes and are heavyweight. Also, it is not possible to work with an SLS printer in a closed area because when the powder is fused by laser it generates fumes so it needs ventilation to eject these fumes. Benchtop industrial systems start from 18000$.

Polymers powder comes in medium-range in comparison to high-quality SLA resin. But SLS does not have much variety for more variety you can try their mix. But in SLS printing, your prints do not require support so your powder is not going to waste you can reuse your excess powder. To reuse excess powder you need to add some fresh material incorrect ratio, this ratio is defined by the manufacturer. Reusing the powder is a reason you have cheap SLS prints.

If you have SLS printed part you can see that its surface is not smooth it feels grainy for the smooth surface you need blasting with plastic beads or tumbling which makes its surface smooth. This process will cost you both time and some money.

Miscellaneous Differences Between SLA printing & SLS Printing

Mechanical Properties

SLA Print result of solidification of the part because of exposing of light. SLA part mechanical property performance depends on the material type although it is brittle. But you can also find expensive engineering resin which gives you maximum engineering properties. Some resin gives you a highly flexible print. While Ceramic resin print after post-processing gives your printability to withstand high-temperature flame.

SLS print surface is grainy which feels brittle but it’s only at the surface while the print is strong and good for mechanical works due to the strong bond between layers.

Complex Designing

Yes, we can print complex designs in SLA 3d printer but it is also true that if you need complex internal geometry then we should accept some difficulties, sometimes because when your design has support internally so it becomes impossible to remove them from their else if this support is in the internal hollow tube then it causes a problem. When you slice your 3d model at that time you can check whether the part required support on which areas.

SLS printer uses their unfused powder as support so when you slice your 3d model for SLS printer then it does not show or need any support for the model. This also helps when your print model has an internal hollow tube or any other type of internal structure, when the print is finished you can remove the unfused powder from it, and this is a cumbersome task on its own.

Variety Of Material

SLA printer is cheap but its resin is expensive. Although they come in a wide variety of the type, surface finish, Color, Mechanical properties, thermal properties, flexibility, castable property and yes also quality type. A good quality resin with a resolution SLA printer gives you high detail print with a smooth surface finish. Some SLA 3d printer manufacturers sell their brand resin for better work.

SLS printer uses polymer powder which does not have multiple types most of the time Nylon polymer powder is used for manufacturing but sometimes their composite also be used. Nylon 11 and Nylon 12 mostly use materials in SLS printing.

Conclusion

As you read different aspects about SLA Vs SLS both printing technology is useful in their field of application. SLA Printer provides you high detailed print with a smooth surface finish with some mechanical limitations while SLS print provides you the ability to design complex geometrical shapes with good mechanical performance.

When you have designed some translucent or transparent object SLA printer fulfills your dreams without any hesitations. Ceramic resin or castable resin is able to withstand in front of high temperatures after post-processing. SLA provides a higher resolution than SLS that’s by is used by the dentist for mold forming.

With an SLS printer, you directly print your product’s final version for physical checkups in design. SLS gives your print injection molded part strength because of the good bond between layers. Due to being submerged in polymer powder the surface of the print gives a grainy effect but after some post-processing, you can make your part smooth.

SLS printers are used as mass production devices because of their robustness and high throughput. In the SLS process, you do not waste any material you are able to use the unfused material in the next print with some addition of fresh material. This decreases the cost of each print.

I hope this sums up the topic, if you have any questions please ask in the comment box below. Thank You